Hydrothermal preparation method and application of magnetic ferroferric oxide nanochain

A technology of ferric tetroxide and nano-chain, applied in the field of nano-materials, can solve the problems of surface modification of unfavorable materials, large irritation of tetrahydrofuran, large particle size of nano-crystal clusters, etc., achieves good potential application prospects, novel and simple preparation method, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0027] Specific embodiment one: with 2 mol FeCl 3 6H 2 O and 2 mol of anhydrous sodium acetate were added to a 100 ml three-neck flask, stirred and mixed for 5 minutes, and 260 mol of ethylene glycol was quickly added, and after 20 minutes of mechanical stirring to obtain a cloudy orange-yellow solution, slowly added 60 mol amine surfactant ethylenediamine, and mechanically stirred for 30 minutes to obtain an orange viscous liquid, stop stirring, measure 70 ml of the mixed liquid into a polytetrafluoroethylene autoclave, put it into an iron shell to seal, and put In a constant temperature oven at 180°C, react for 8 hours. After the polytetrafluoroethylene autoclave was naturally cooled to room temperature, it was taken out, ultrasonically cleaned with absolute ethanol several times until the particles were clean, and then dried in a vacuum oven at 60°C for 12 hours to obtain magnetic Fe3O4 nanochains.

[0028]

specific Embodiment 2

[0029] Specific embodiment two: with 2mol FeCl 3 6H 2 O and 7 mol of anhydrous sodium acetate were added to a 100 ml three-neck flask, stirred and mixed for 5 minutes, and 290 mol of ethylene glycol was quickly added, and after 20 minutes of mechanical stirring to obtain a cloudy orange-yellow solution, slowly added 82 mol amine surfactant triethylenetetramine, and mechanically stirred for 30 minutes to obtain an orange-yellow viscous liquid, stop stirring, measure 60 ml of the mixed liquid into a polytetrafluoroethylene autoclave, put it into an iron shell to seal, and place Put it into a constant temperature oven at 170°C, and react for 7.5 hours. After the polytetrafluoroethylene autoclave was naturally cooled to room temperature, it was taken out, ultrasonically cleaned with absolute ethanol several times until the particles were clean, and then placed in a vacuum oven at 60°C for 12 hours to obtain magnetic Fe3O4 nanochains.

[0030]

specific Embodiment 3

[0031] Specific embodiment three: with 2 mol FeCl 3 6H 2 O and 10 mol of anhydrous sodium acetate were added to a 100 ml three-necked flask, stirred and mixed for 5 minutes, and 360 mol of ethylene glycol was quickly added, and after 20 minutes of mechanical stirring to obtain a cloudy orange-yellow solution, slowly added 100 mol of amine surfactant disodium ethylenediaminetetraacetate, and mechanically stirred for 30 minutes to obtain an orange viscous liquid, stop stirring, measure 80 ml of the mixed solution to a polytetrafluoroethylene autoclave, and put it into an iron The shell was closed, placed in a constant temperature oven at 200°C, and reacted for 9 hours. After the polytetrafluoroethylene autoclave was naturally cooled to room temperature, it was taken out, ultrasonically cleaned with absolute ethanol several times until the particles were clean, and then dried in a vacuum oven at 60°C for 12 hours to obtain magnetic Fe3O4 nanochains.

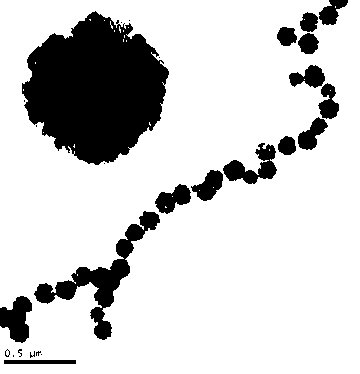

[0032] Such as figure 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

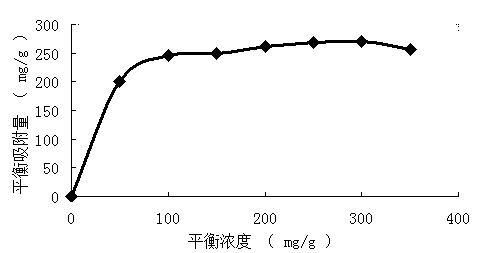

| Maximum saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com