Method for preparing nano aluminum oxide material modified polymer integral column

A nano-alumina and monolithic column technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of reduced separation efficiency, poor mechanical strength, and analytical application limitations, and achieve simple preparation methods, stable material properties, and improved The effect of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

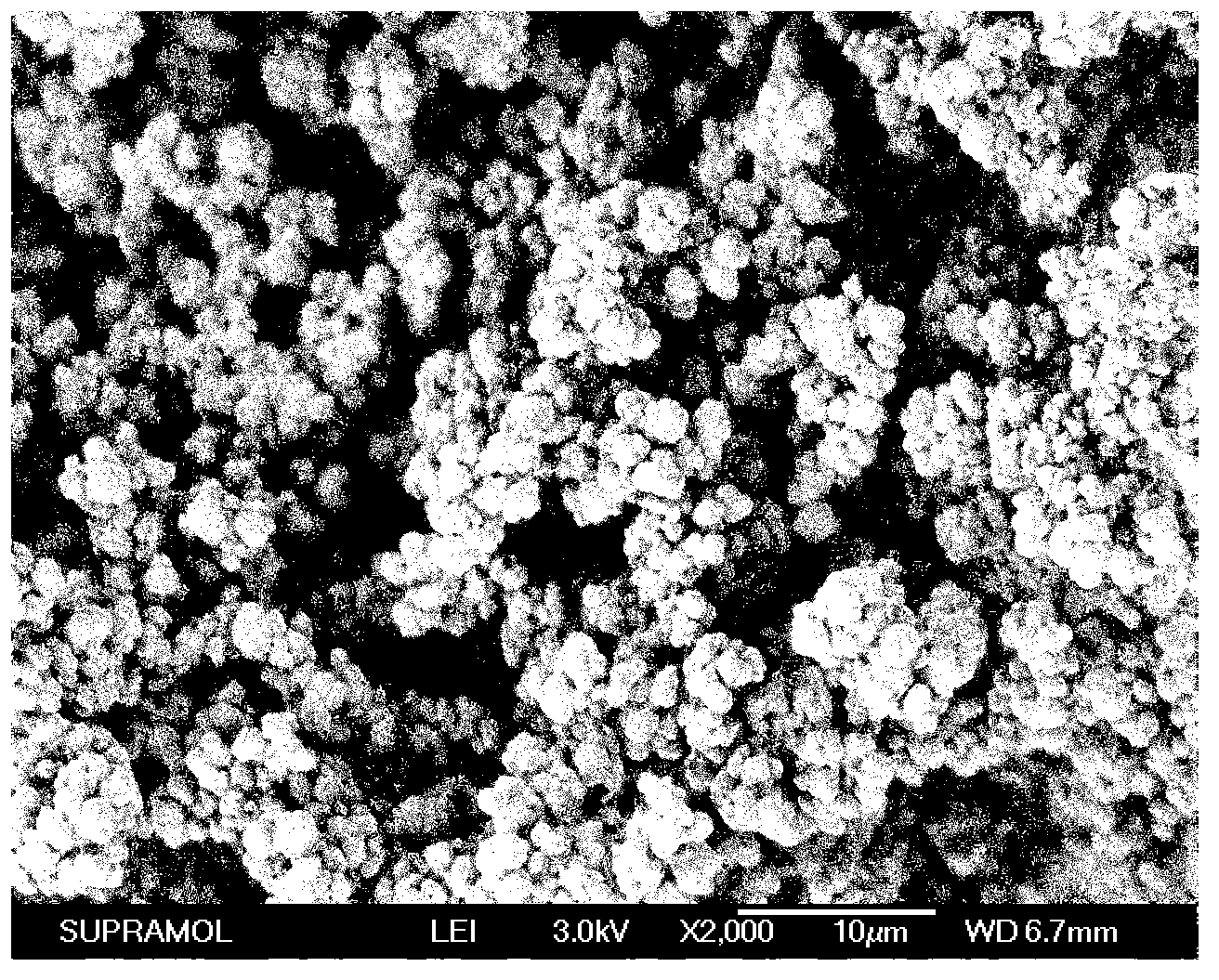

Image

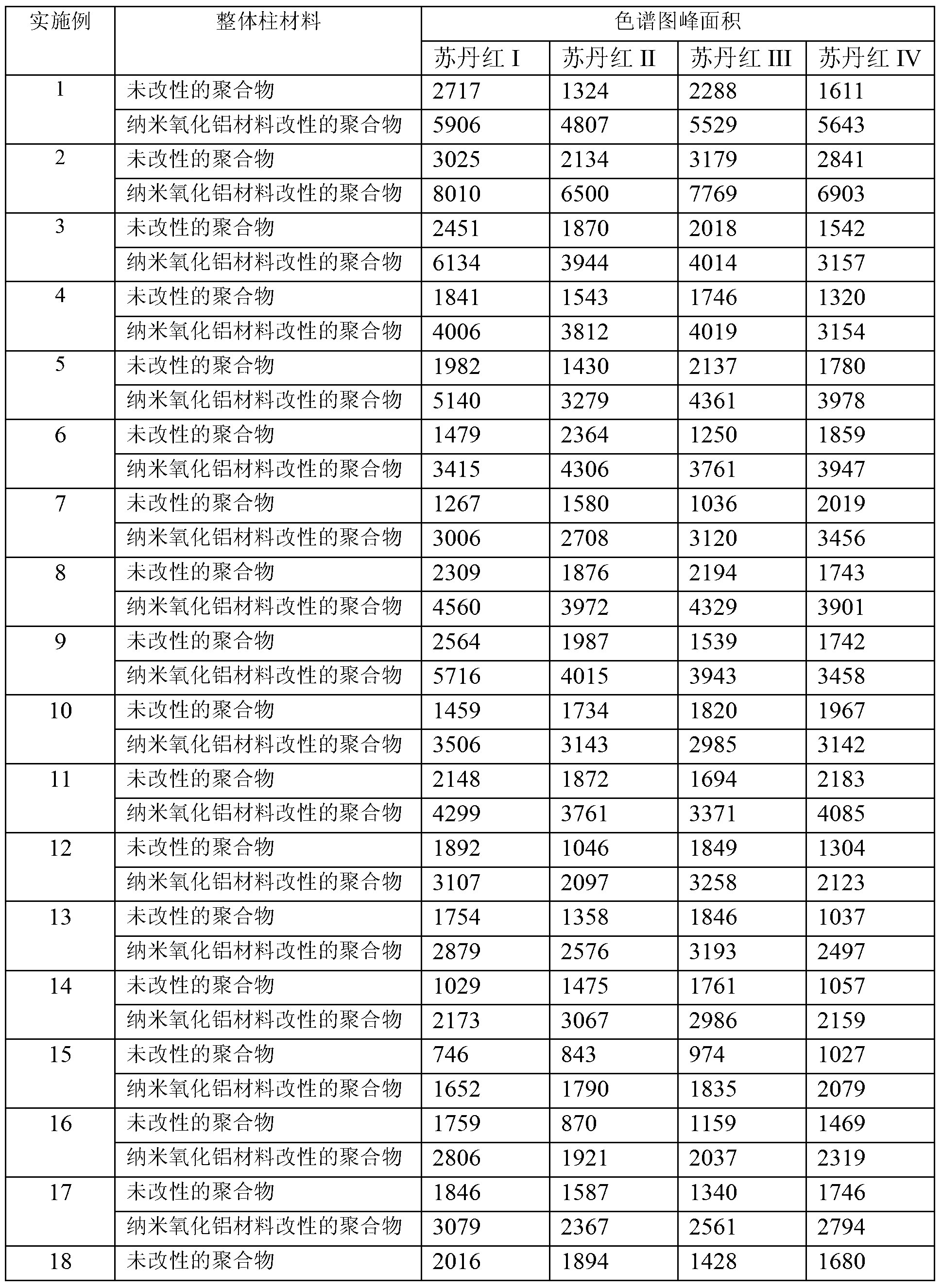

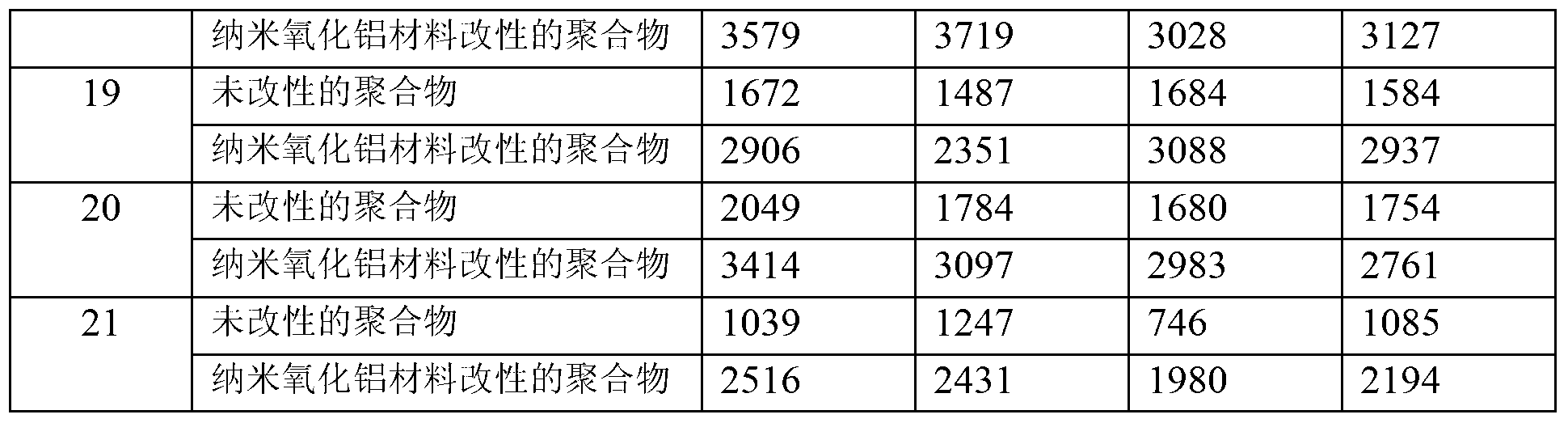

Examples

Embodiment 1

[0020] (1) The functional monomer glycidyl methacrylate, the crosslinking agent ethylene dimethacrylate, the porogen methanol, and the initiator azobisisobutyronitrile are 30.0:70.0:260.0:1.0 according to the mass ratio Mix and stir evenly, inject into silanized quartz capillary, seal, thermally initiate polymerization reaction at 65°C, rinse thoroughly with methanol after completion, and obtain poly(glycidyl methacrylate-ethylene dimethacrylate ester) monolithic column.

[0021] (2) Disperse nano-alumina in a sodium hydroxide solution with a concentration of 0.035mol / L, the concentration of nano-alumina in the sodium hydroxide solution is 4.5mg / mL, and then add nano-alumina-sodium hydroxide solution Excessive injection of poly(glycidyl methacrylate-ethylene dimethacrylate) monolithic column, sealing both ends, heat-initiated polymerization reaction at 65°C, fully rinsed with methanol after completion, to obtain nano-alumina Poly(glycidyl methacrylate-ethylene dimethacrylate)...

Embodiment 2

[0023] (1) The functional monomer glycidyl methacrylate, the crosslinking agent ethylene dimethacrylate, the porogen methanol, and the initiator azobisisobutyronitrile are in a mass ratio of 36.3:63.7:300.0:1.0 Mix and stir evenly, inject into silanized quartz capillary, seal, thermally initiate polymerization reaction at 60°C, rinse thoroughly with methanol after completion, and obtain poly(glycidyl methacrylate-ethylene dimethacrylate ester) monolithic column.

[0024] (2) Disperse the nano-alumina in the sodium hydroxide solution with a concentration of 0.015mol / L, the concentration of the nano-alumina in the sodium hydroxide solution is 5.0mg / mL, and then the nano-alumina-sodium hydroxide solution Excessive injection of poly(glycidyl methacrylate-ethylene dimethacrylate) monolithic column, sealing both ends, heat-initiated polymerization reaction at 60°C, fully rinsed with methanol after completion, to obtain nano-alumina Materials Modified poly(glycidyl methacrylate-ethy...

Embodiment 3

[0026] (1) The functional monomer glycidyl methacrylate, the crosslinking agent ethylene dimethacrylate, the porogen methanol, and the initiator azobisisobutyronitrile are 40.0:60.0:360.0:5.0 according to the mass ratio Mix and stir evenly, inject into silanized quartz capillary, seal, thermally initiate polymerization reaction at 70°C, rinse thoroughly with methanol after completion, and obtain poly(glycidyl methacrylate-ethylene dimethacrylate ester) monolithic column.

[0027] (2) Disperse nano-alumina in a sodium hydroxide solution with a concentration of 0.055mol / L, the concentration of nano-alumina in the sodium hydroxide solution is 5.5mg / mL, and then add nano-alumina-sodium hydroxide solution Excessively inject poly(glycidyl methacrylate-ethylene dimethacrylate) monolithic column, seal both ends, heat-initiate polymerization reaction at 70°C, and fully rinse with methanol after completion to obtain nano-alumina Materials Modified poly(glycidyl methacrylate-ethylene di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com