Synthesis of CeO2-based solid solution nanometer material and application of nanomaterial to catalytic degradation of dye

A technology of nanomaterials and solid solutions, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems affecting sunlight transmission, water color changes, ecological environment, etc. Deterioration and other problems, to achieve the effect of good catalytic performance, adjustable composition, and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 8mmolCe(NO 3 ) 3 ·6H 2 O, 1mmolLa(NO 3 ) 3 ·6H 2 O and 3mmol NaOH were dissolved in 10mL of deionized water, put into the reaction kettle, and reacted in an oven at 240°C for 72h; Dry for 24h to get CeO 2 Based solid solution nanomaterials, denoted as Ce-La-D. Prepared CeO 2 The general structural formula of the base solid solution nanomaterial is: (CeO 2 ) 0.89 (LaO 1.5 ) 0.11 ; The structure of the nanometer material is an octahedron with a uniform shape.

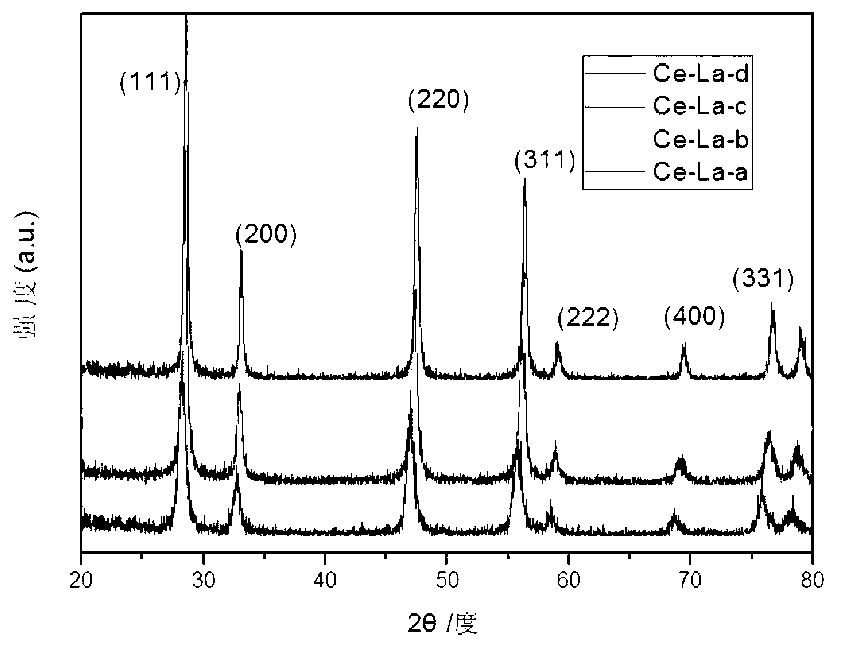

[0023] Adjust the amount of raw materials and prepare CeO with a molar ratio of Ce:La=1:1, 2:1, 4:1 according to the above conditions, that is, the doping ratios are 0.5, 0.33, and 0.2 respectively. 2 Based solid solution nanomaterials, respectively marked as Ce-La-A, Ce-La-B, Ce-La-C.

[0024] The prepared product was qualitatively analyzed by ShimaduXRD-6000 powder X-ray diffractometer, and the morphology of the sample was analyzed by JEOLJEM-2100 transmission electron microscope and high-resol...

Embodiment 2

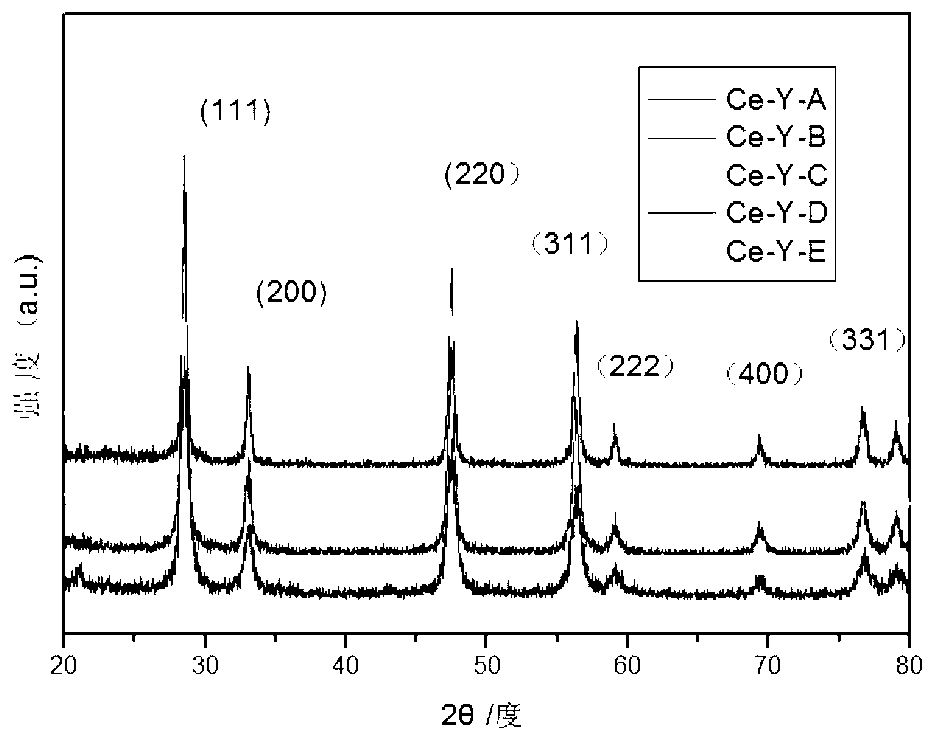

[0033] Weigh 1mmolCe(NO 3 ) 3 ·6H 2 O, 1mmolY (NO 3 ) 3 ·6H 2 O (molar ratio Ce:Y=1:1) and 3mmolNa 3 PO 4 Dissolve it in 10mL of deionized water, put it into a reaction kettle, and react in an oven at 240°C for 72h; after cooling, wash it with deionized water to pH=7, and dry the obtained solid in an oven at 60°C for 24h. That is, CeO 2 Based solid solution nanomaterials, denoted as Ce-Y-A. Prepared CeO 2 The general structural formula of the base solid solution nanomaterial is: (CeO 2 ) 0.5 (YO 1.5 ) 0.5 The structure of the nanometer material is octahedron with uniform appearance, and the grain size is 10-40nm.

[0034] Adjust the amount of raw materials and prepare CeO with a molar ratio of Ce:Y=2:1, 4:1, 8:1, and 9:1 according to the above conditions, that is, the doping ratios are 0.33, 0.2, 0.11, and 0.1 respectively. 2 Based solid solution nanomaterials, respectively marked as Ce-Y-B, Ce-Y-C, Ce-Y-D, Ce-Y-E.

[0035] The same XRD peaks indicate that solid...

Embodiment 3

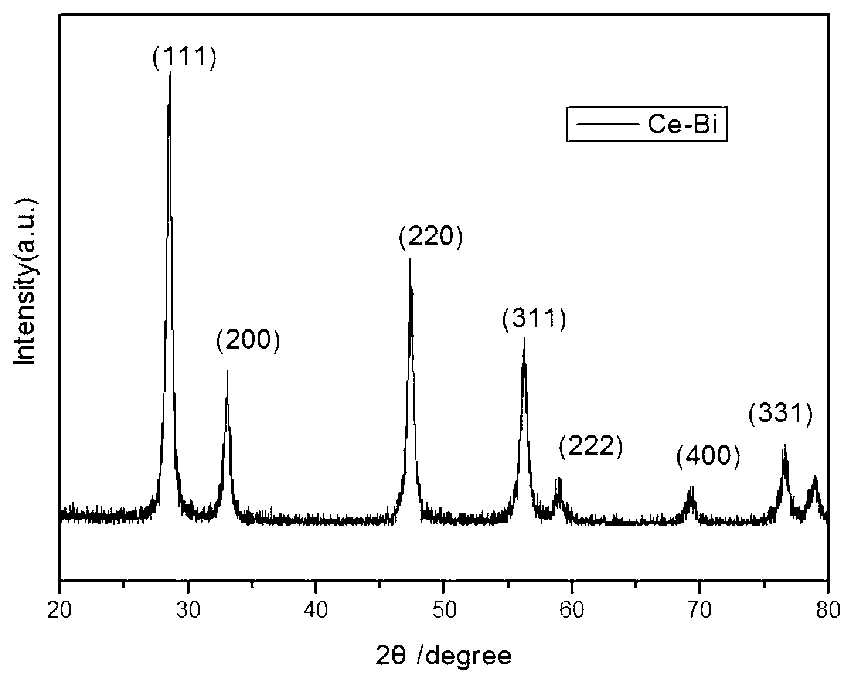

[0038] Weigh 9mmolCe(NO 3 ) 3 ·6H 2 O, 1 mmol BiCl 3 ·6H 2 O (molar ratio Ce:Bi=9:1) and 3mmol NaOH were dissolved in 10mL of deionized water, placed in a reaction kettle, and reacted in an oven at 240°C for 72h; 7. Dry the obtained solid in an oven at 60°C for 24 hours to obtain CeO 2 based solid solution nanomaterials.

[0039] CeO prepared above 2 The general structural formula of the base solid solution nanomaterial is: (CeO 2 ) 0.9 (BiO 1.5 ) 0.1 The structure of the nanometer material is octahedron with uniform appearance, and the grain size is 10-40nm.

[0040] XRD shows that the solid solution (CeO 2 ) 0.9 (BiO 1.5 ) 0.1 .

[0041] The above-prepared CeO 2 Based solid solution nanomaterials are used in the photocatalytic degradation of acid orange 7, the reaction conditions are: take CeO 2 Put 5 mg of base solid solution nanomaterials in a quartz cuvette, then add 3 mL of Acid Orange 7 solution with a concentration of 10 ppm, put it into a visible ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com