Method for lowering down proportion of by-product produced in fermentation of demethylchlortetracycline

A technology of demethylaureomycin and by-products, which is applied in the field of reducing the proportion of by-products in demethylaureomycin fermentation, can solve the problems of no attention to DMTC, difficult DMTC, low antibacterial activity, etc., and achieve the reduction of by-product demethylation The ratio of base tetracycline, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Under the condition of above-mentioned seed culture, the seed liquid that makes is inserted in fermentor and cultivated according to above-mentioned fermenting culture condition, and the fermented medium in the fermentor in described fermentor except above-mentioned composition, has added the cupric chloride of 150ppm, During the fermentation process, ammonia water is used to adjust the pH value of the fermentation broth, so that the pH value of the fermentation broth is controlled to be 6.4 for 0-50 hours, 6.2 for 51-100 hours, and 6.0 for 101-release tanks.

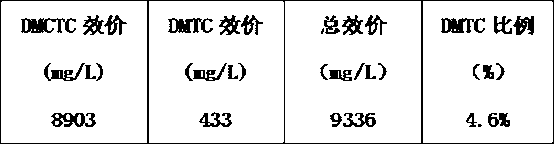

[0030] When the fermentation was terminated, the titer of DMCTC and DMTC was carried out by high pressure liquid chromatography (HPLC), and the results are shown in Table 4.

[0031] Table 2 Results of the fermenter control group

[0032]

[0033] The separation and purification of DMCTC was carried out according to the above method, and the total yield of the product was 73%. Analysis by HPLC showed that the...

Embodiment 2

[0035] Except that the pH value control points are different, other process conditions are the same as in Example 1. During the fermentation process, ammonia water is used to adjust the pH value of the fermentation liquid, so that the pH value of the fermentation liquid is controlled to be 6.3 for 0-50 hours and 6.1 for 51-100 hours. , 101-5.9 when putting the tank.

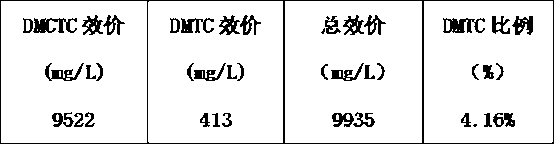

[0036] When the fermentation was terminated, the titer of DMCTC and DMTC was carried out by high pressure liquid chromatography (HPLC), and the results are shown in Table 4.

[0037] Table 3 Results of the fermenter control group

[0038]

[0039] The separation and purification of DMCTC was carried out according to the above method, and the total yield of the product was 76%. Analysis by HPLC showed that the purity of DMCTC was 95.3%, the purity of DMTC was 3.1%, and other impurities accounted for 1.6%.

Embodiment 3

[0041] Except that the pH value control points are different, other process conditions are the same as in Example 1. In the fermentation process, ammonia water is used to adjust the pH value of the fermentation liquid, so that the pH value of the fermentation liquid is controlled to be 6.2 for 0-50 hours and 6.0 for 51-100 hours. , 101-5.8 when putting the tank.

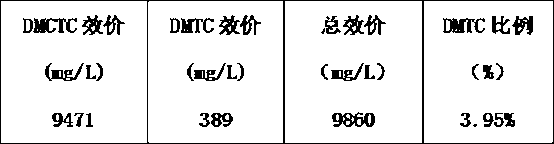

[0042] When the fermentation was terminated, the titer of DMCTC and DMTC was carried out by high pressure liquid chromatography (HPLC), and the results are shown in Table 4.

[0043] Table 4 Results of the fermenter control group

[0044]

[0045] The separation and purification of DMCTC was carried out according to the above method, and the total yield of the product was 71%. Analysis by HPLC showed that the purity of DMCTC was 94.1%, the purity of DMTC was 3.3%, and other impurities accounted for 2.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com