Automotive brake block with ionic type rare-earth residues as filling materials

An ionic rare earth, automobile braking technology, applied in the direction of friction lining, mechanical equipment, etc., can solve the problems of friction coefficient decrease, oxidation decomposition phenomenon, etc., and achieve the effect of stable friction coefficient, environmental protection, and good thermal fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

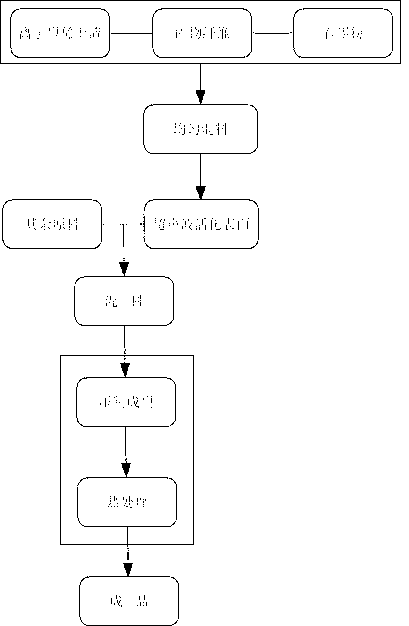

Method used

Image

Examples

Embodiment 1

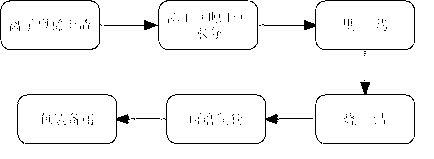

[0011] Embodiment 1: by weight, 12 parts of ionic rare earth slag, 35 parts of mineral fiber, 12 parts of binder, 15 parts of graphite, 3 parts of high-temperature binder, 2 parts of aramid reinforcing fiber, 8 parts of friction-increasing material, 13 parts of modifiers such as friction powder. Among them, the ionic rare earth slag is the waste residue after refining the ionic rare earth in the south, which is made by filtering or drying the surface moisture, baking, heating and sintering, and grinding into powder. Its shape is powder granular; the mineral fiber is silicate Natural inorganic mineral fiber; binder is thermoplastic phenolic resin; graphite is flake graphite; high-temperature binder is metal sulfide, etc.; friction-increasing materials are fluorite powder and alumina. Among them, the ionic rare earth slag is the waste residue after refining the ionic rare earth, which is obtained by filtering or drying the surface moisture, baking, heating and sintering, and gri...

Embodiment 2

[0017] Embodiment 2: by weight, 15 parts of ionic rare earth slag, 35 parts of mineral fiber, 12 parts of binder, 15 parts of graphite, 3 parts of high-temperature binder, 2 parts of aramid reinforcing fiber, 8 parts of friction-increasing material, 10 parts of modifiers such as friction powder. Among them, the ionic rare earth slag is the waste residue after refining the ionic rare earth in the south, which is made by filtering or drying the surface moisture, baking, heating and sintering, and grinding into powder. Its shape is powder granular; the mineral fiber is silicate Natural inorganic mineral fiber; binder is thermoplastic phenolic resin; graphite is flake graphite; high temperature binder metal sulfide, etc. Among them, the ionic rare earth slag is the waste residue after refining the ionic rare earth, which is obtained by filtering or drying the surface moisture, baking, heating and sintering, and grinding, and its shape is in the form of powder particles, such as ...

Embodiment 3

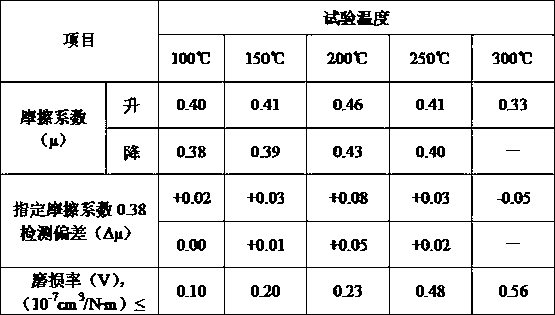

[0023] Embodiment 3: by weight, mineral filler contains 12 parts of barium sulfate of 98%, 35 parts of mineral fiber, 12 parts of binder, 15 parts of graphite, 3 parts of high-temperature binder, 2 parts of aramid reinforcing fiber, friction increasing 8 parts of materials, 13 parts of modifiers such as friction powder. The mineral fiber is silicate-type natural inorganic mineral fiber; the binder is thermoplastic phenolic resin; the graphite is flake graphite; the high-temperature binder is metal sulfide; the friction-increasing material is fluorite powder and alumina. After the mineral fiber and graphite raw materials are evenly mixed, ultrasonic treatment is used to mechanically activate the surface of the particles to enhance the contact force between the particles; and then mixed with the rest of the raw materials and solidified into brake pads through compression molding and heat treatment.

[0024] According to the above formula design, the product samples are processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com