Method for extracting methane contained in low-concentration oxygen-containing coal-seam gas

A coalbed methane, low-concentration technology, used in lighting and heating equipment, liquefaction, solidification and other directions, can solve the problems of increasing deoxidation equipment, sacrificing methane recovery rate, increasing equipment investment and operating costs, and improving production efficiency and reducing equipment. effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

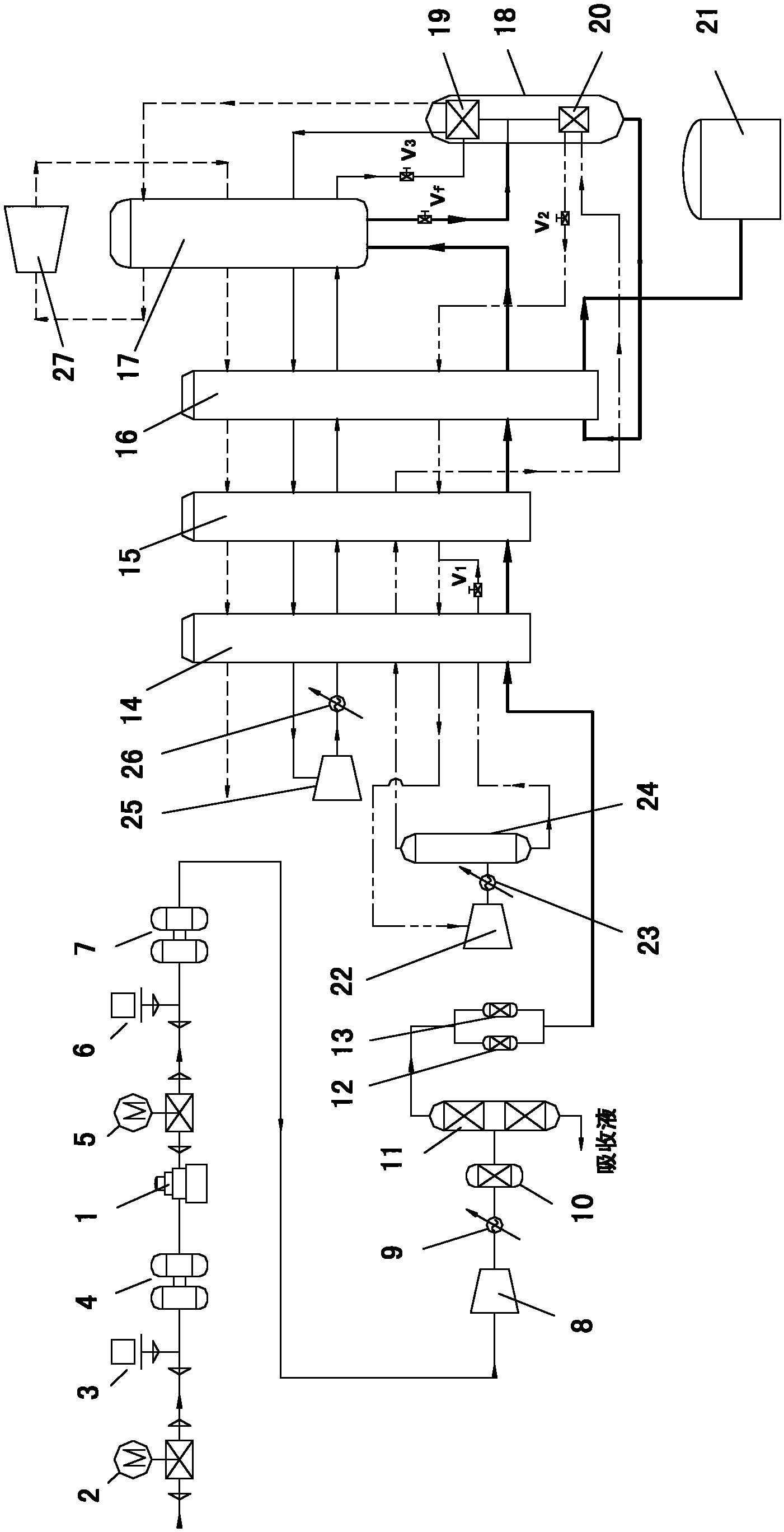

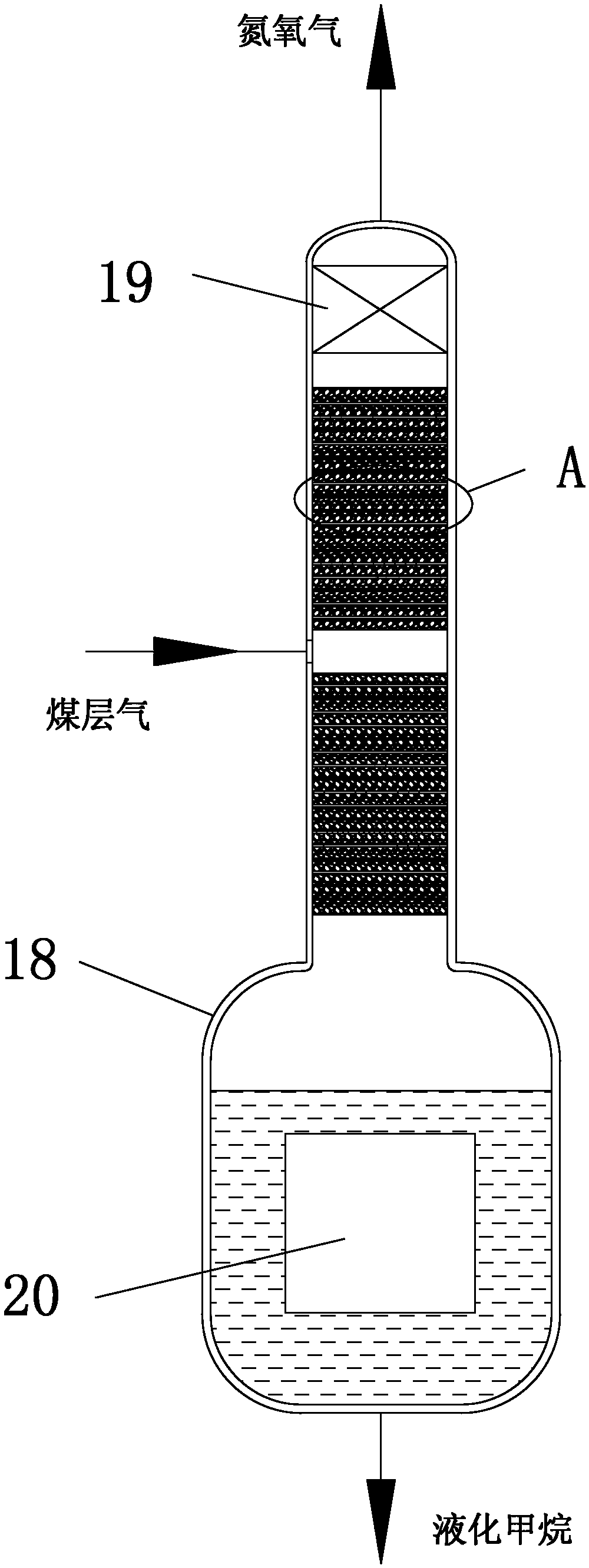

[0038] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

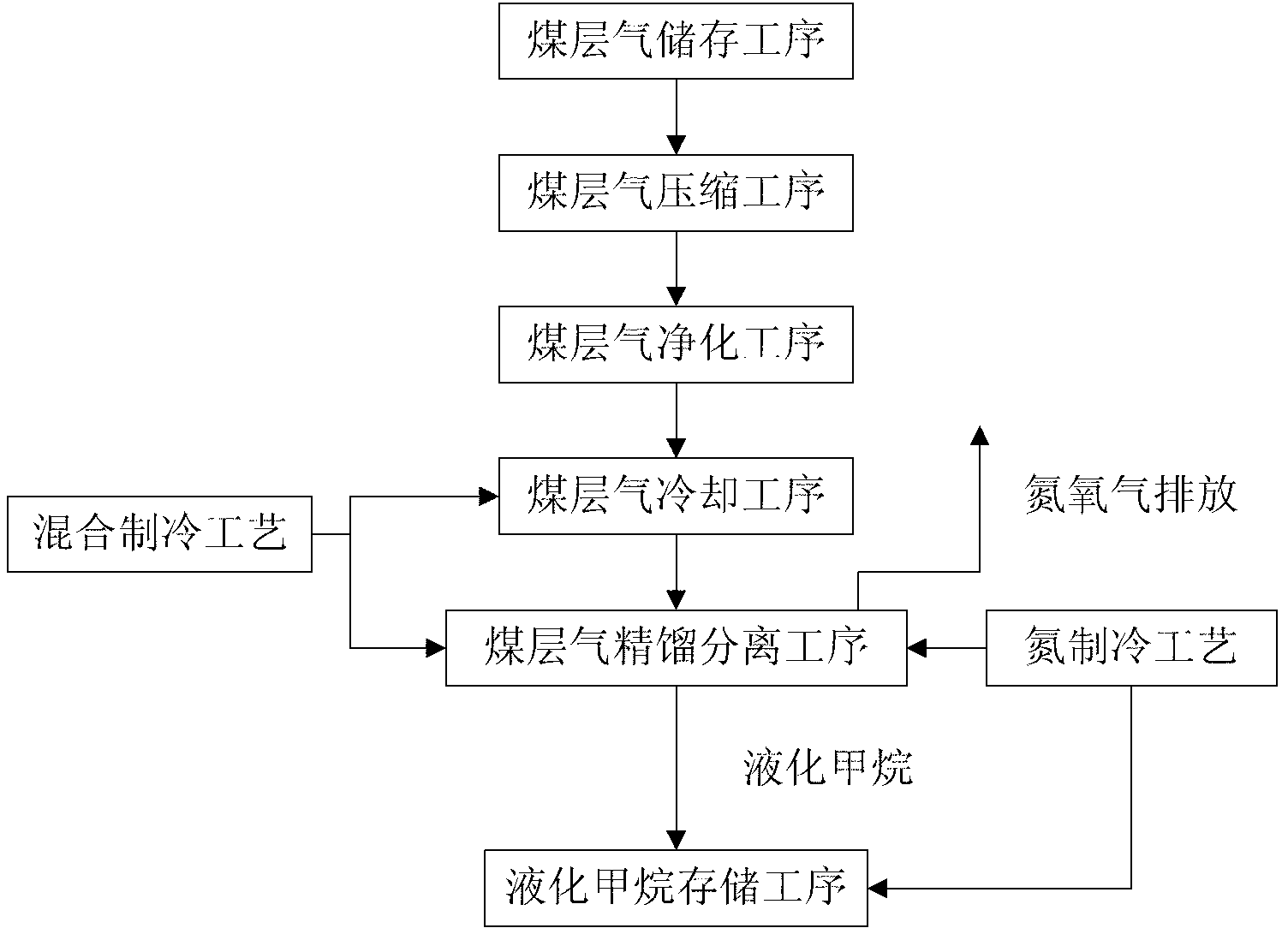

[0039] Such as figure 1 Shown is a process flow diagram of the method for extracting methane in low-concentration oxygen-containing coalbed methane according to the present invention. The method for extracting methane in low-concentration oxygen-containing coalbed methane of the present invention includes the following steps.

[0040] 1) Coalbed methane storage process: use gas cabinet 1 to store low-concentration oxygen-containing coalbed methane, and the storage pressure is 0.001MPa~0.005MPaG. Preferably, the air intake pipeline of the gas cabinet 1 is provided with an automatic explosion-preventing valve 2, a powder spraying explosion suppression device 3 and a water seal fire arresting explosion relief device 4, and the powder spraying explosion suppression device 3 is located before the water seal fire arresting explosion relief device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com