Nano-crystalline soft magnetic material high in saturation magnetization intensity and preparation method of nano-crystalline soft magnetic material

A technology of nanocrystalline soft magnetism and magnetization, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., and can solve problems such as improving the soft magnetic properties of Fe-B-based nanocrystalline alloys and reducing the saturation magnetization of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

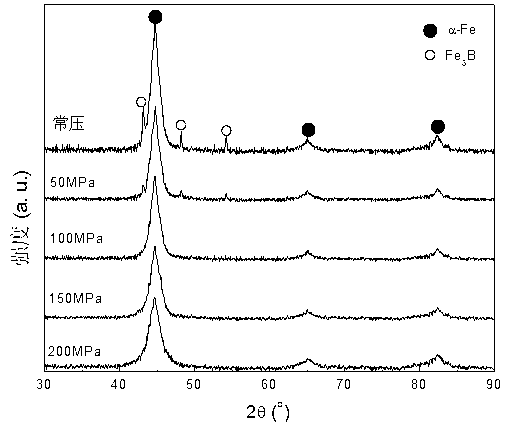

[0014] Weigh 602g of pure iron powder, 17.8g of boron powder, and 8g of copper powder, and prepare Fe by vacuum smelting. 86 B 13 Cu 1 Alloy ingots, and then prepared by single-roll rapid quenching Fe 86 B 13 Cu 1 The amorphous strips are 20 μm thick and 10 mm wide, and are annealed under normal pressure at a temperature of 410° C. for 1 h. Get Fe 86 B 13 Cu 1 The precipitated phase composition of nanocrystalline soft magnetic materials is α -Fe+ a small amount of Fe 3 B (see attached picture), where α - the grain size of the Fe nanoparticles, α -Volume fraction of Fe, Fe 86 B 13 Cu 1 The resistivity, saturation magnetization, coercive force, initial permeability and relaxation frequency of nanocrystalline soft magnetic materials are 22.5nm, 57.8%, 62μΩcm, 1.71T, 3489A / m, 9.8×10 3 and 4.2×10 5 Hz.

Embodiment 2

[0016] Weigh 602g of pure iron powder, 17.8g of boron powder, and 8g of copper powder, and prepare Fe by vacuum smelting. 86 B 13 Cu 1 Alloy ingots, and then prepared by single-roll rapid quenching Fe 86 B 13 Cu 1 The amorphous strip is 20 μm thick and 10 mm wide, and the amorphous Fe 86 B 13 Cu 1 The strip is annealed, the pressure of hot isostatic pressing is 50Mpa, the annealing temperature is 410°C, and the time is 1h. Get Fe 86 B 13 Cu 1 The precipitated phase composition of nanocrystalline soft magnetic materials is α -Fe+trace Fe 3 B (see attached picture), where α - the grain size of the Fe nanoparticles, α -Volume fraction of Fe, Fe 86 B 13 Cu 1 The resistivity, saturation magnetization, coercive force, initial permeability and relaxation frequency of nanocrystalline soft magnetic materials are 17.8nm, 60.2%, 68μΩcm, 1.82T, 900A / m, 1.4×10 4 and 1.9×10 5 Hz.

Embodiment 3

[0018] Weigh 602g of pure iron powder, 17.8g of boron powder, and 8g of copper powder, and prepare Fe by vacuum smelting. 86 B 13 Cu 1 Alloy ingots, and then prepared by single-roll rapid quenching Fe 86 B 13 Cu 1 The amorphous strip is 20 μm thick and 10 mm wide, and the amorphous Fe 86 B 13 Cu 1 The strip is annealed, the pressure of hot isostatic pressing is 100Mpa, the annealing temperature is 410°C, and the time is 1h. Get Fe 86 B 13 Cu 1 The precipitated phase composition of nanocrystalline soft magnetic materials is α -Fe (see attached figure), where α - the grain size of the Fe nanoparticles, α -Volume fraction of Fe, Fe 86 B 13 Cu 1 The resistivity, saturation magnetization, coercivity, initial permeability and relaxation frequency of nanocrystalline soft magnetic materials are 15.0nm, 68.9%, 164μΩcm, 1.88T, 34A / m, 7.7×10 4 and 5.6×10 4 Hz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com