Method for producing glass substrate for flat panel display

A flat panel display and glass substrate technology, applied in glass manufacturing equipment, glass forming, glass forming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] (Production of sample glass)

[0121] Silicon dioxide, alumina, boron oxide, potassium carbonate, basic magnesium carbonate, calcium carbonate, strontium carbonate, tin dioxide, and ferric oxide were used as glass compositions shown in Table 1. , Blend glass raw material batch (hereinafter referred to as batch).

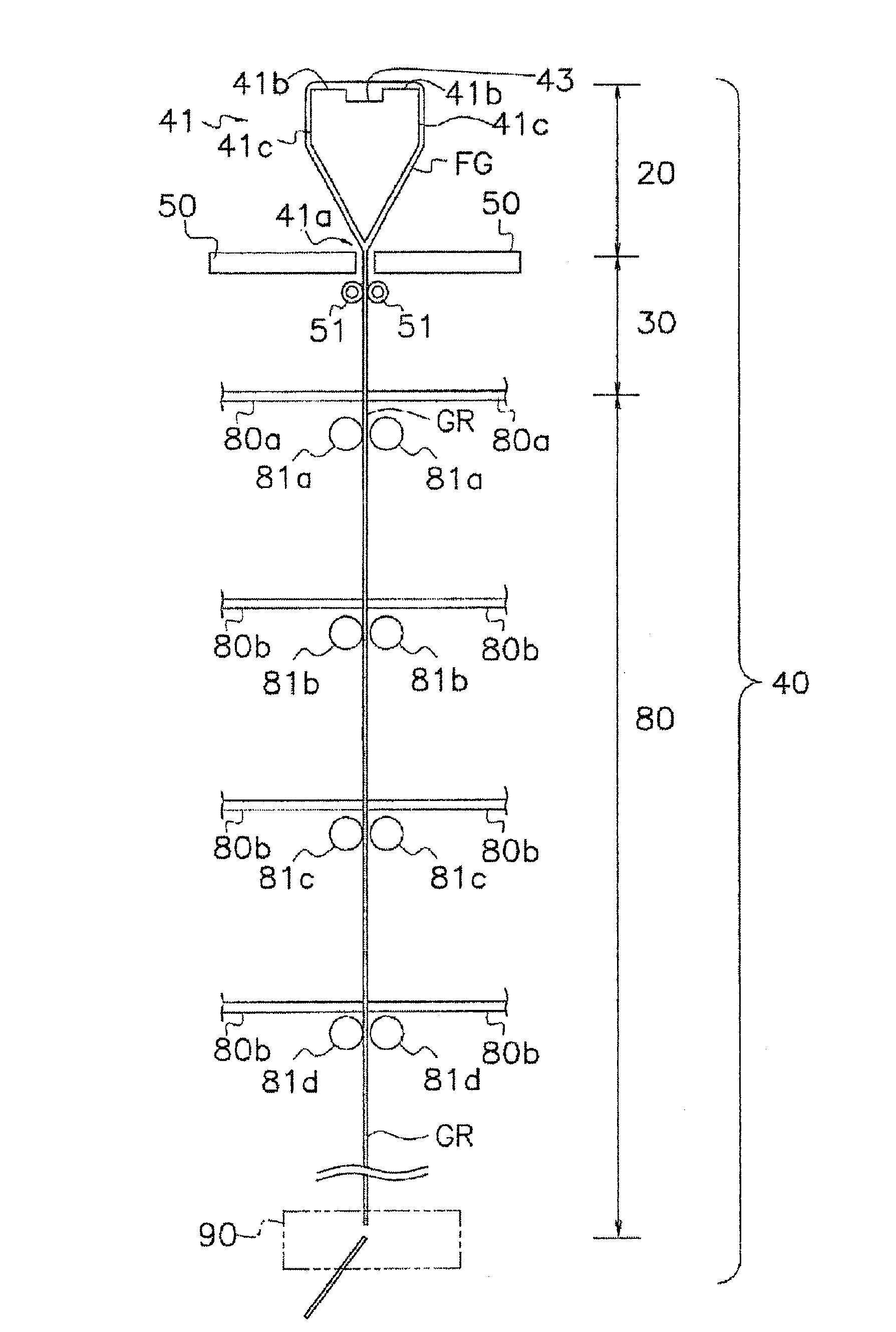

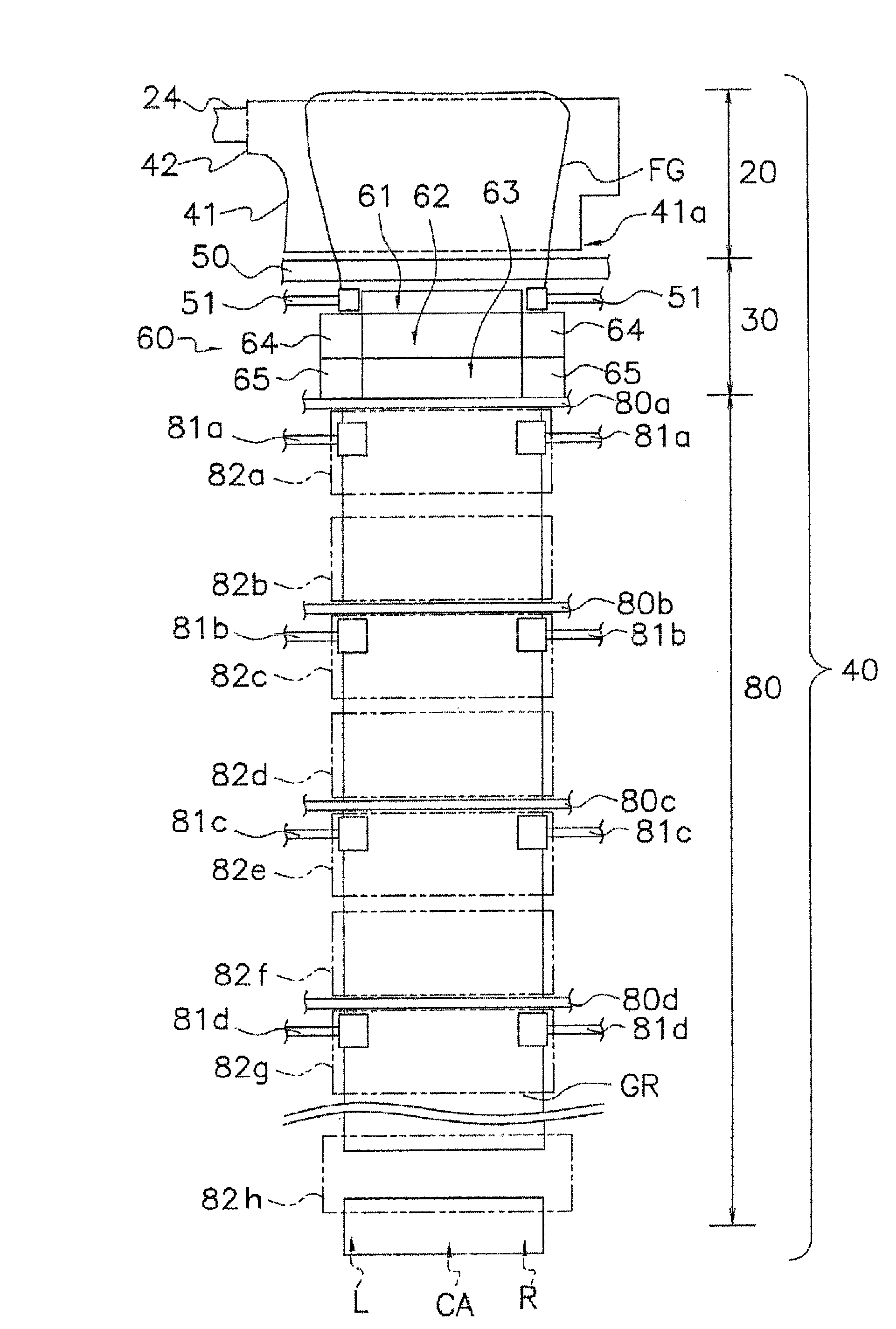

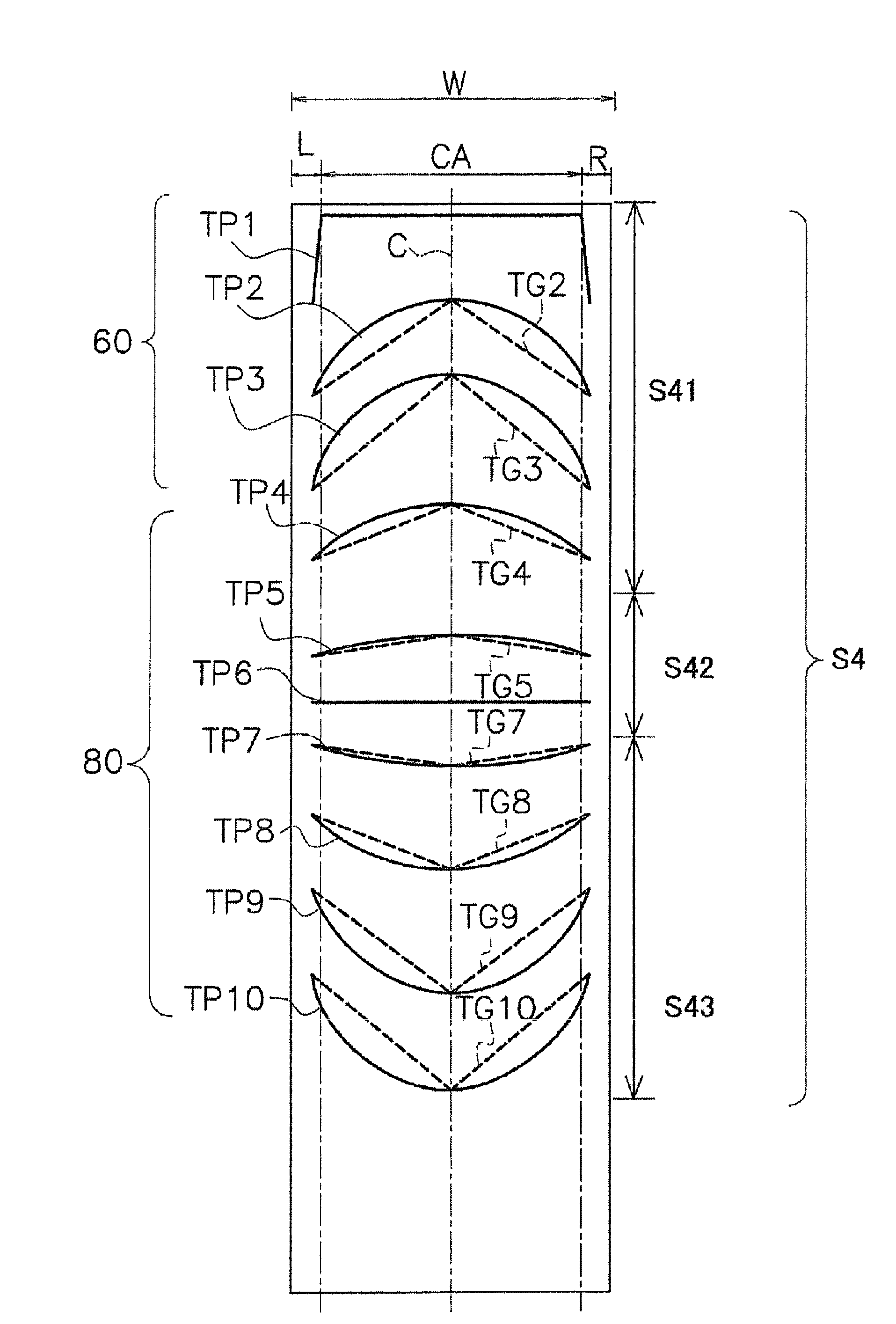

[0122] The above blended batch is melted at 1560-1640°C using a continuous melting device equipped with a refractory brick melting tank and a platinum alloy adjusting tank, clarified at 1620-1670°C and stirred at 1440-1530°C. use figure 1 and 2 The manufacturing device of the glass substrate shown is formed into a glass ribbon GR with a width of 1600 mm and a thickness of 0.7 mm by the overflow down-draw method, and annealed under prescribed conditions to obtain glass for liquid crystal displays (for organic EL displays) substrate. The prescribed annealing conditions are shown in Tables 2-6. Moreover, about each characteristic below, the glass substrate f...

Embodiment 2

[0155] Glass composition (mol%), devitrification temperature (°C), annealing point (°C), strain point (°C), average thermal expansion coefficient (×10 -7 ℃ -1 ), density (g / cm 3 ), Young's modulus (GPa), specific elastic modulus, melting temperature (°C), liquid viscosity (dPa·s), Tg (°C) and specific resistance (Ω·cm) are shown in Table 1. Moreover, the width|variety of glass ribbon GR is 1600 mm, and thickness is 0.7 mm.

[0156]Tables 6-7 show the temperature change (degreeC) of glass ribbon GR in cooling process S4, and the actual measurement value of the time (second) required for temperature change, and the average cooling rate (degreeC / second) of center part C of glass ribbon GR. Tables 6 to 7 show values when the average cooling rate (°C / sec) in S42 is 2.1 and 3.0, respectively. Furthermore, Table 8 shows the thermal contraction rate of the glass substrate manufactured when the average cooling rate (degreeC / second) in S42 was 2.1 and 3.0, respectively.

[0157] [...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com