Phosphate salt plant growth conditioning agent and application thereof

A technology of plant growth regulators and phosphate ester salts, which is applied in the direction of plant growth regulators, plant growth regulators, applications, etc., and can solve the problems of easy phytotoxicity caused by improper use, high concentration requirements, and difficult compounding, etc. Achieve good synergistic compatibility performance, improve comprehensive functions, and improve safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 15

[0027] Synthesis of example 15-nitroguaiacol phosphate potassium salt

[0028]

[0029] Add 16.9g (0.1mol) of 5-nitroguaiacol and 100mL of chloroform into a 250mL reaction flask, stir to dissolve, add 15.2g (0.1mol) of phosphorus oxychloride dropwise at room temperature, stir at room temperature for 1h, and cool in an ice bath. Warm at 0-10°C, add 0.1mol saturated potassium carbonate aqueous solution dropwise, after dropping, stir at room temperature for 2 hours, thin layer chromatography (TLC) detects that 5-nitroguaiacol has completely reacted, control temperature at 20-40°C, add dropwise 20 % potassium hydroxide solution until the pH of the reaction solution was 7, and the solvent and water were distilled off to obtain 22 g of a white powdery solid with a yield of 71%.

[0030] Can prepare o-nitrophenol phosphate potassium salt and p-nitrophenol phosphate potassium salt according to example 1 method.

example 24

[0031] Preparation of Example 24-Hydroxycoumarin Phosphate Potassium Salt

[0032]

[0033] Add 16.8g (0.1mol) of 4-hydroxycoumarin, 100mL of ethyl acetate and 0.1mol of triethylamine into a 250mL reaction flask, and add 15.2g (0.1mol) of triethylamine dropwise at 0-10°C. The mixed solution of phosphorus oxychloride and 30mL ethyl acetate, after dripping, stirred at room temperature for 2h, thin layer chromatography (TLC) detected that the raw material point disappeared, filtered out triethylamine hydrochloride, and the filtrate was neutralized to pH with potassium hydroxide solution 7, the solvent and water were distilled off to obtain 20 g of a light yellow powdery solid, with a yield of 68%;

example 3 30

[0034] Preparation of Example 3 Triacontanol Phosphate Potassium Salt

[0035] In a 250mL reaction flask, add 8.8g (0.02mol) of triacontanol, 100mL of dichloroethane and 13.8g (0.1mol) of potassium carbonate powder, and dropwise add 3.04g ( 0.02mol) of the mixture of phosphorus oxychloride and 10mL dichloroethane, drop it, stir at room temperature for 2h, thin layer chromatography (TLC) detects that the raw material disappears, neutralize to pH 7 with 20% potassium hydroxide solution, evaporate solvent and water to obtain 15 g of off-white powdery solid.

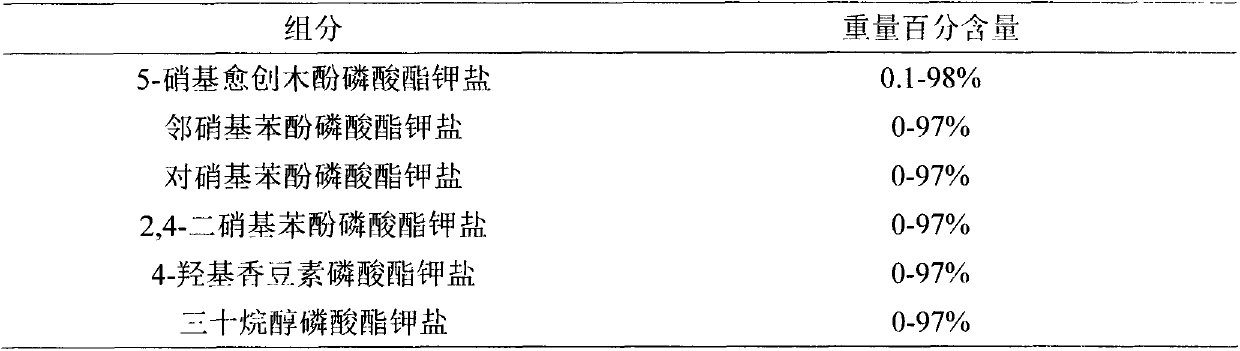

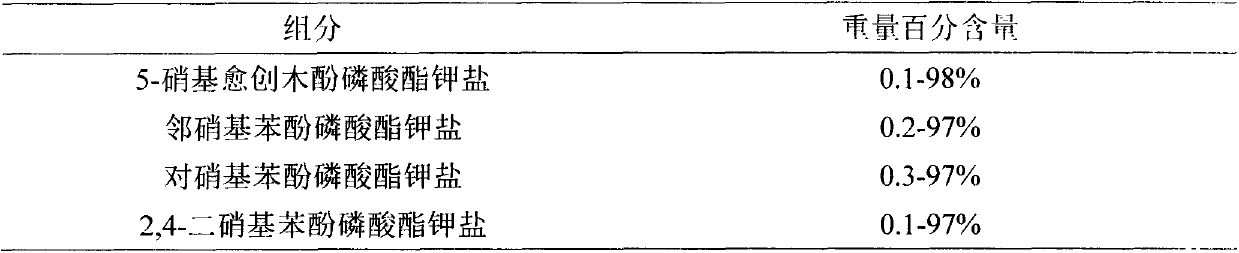

[0036] The melting point of above-mentioned part phosphate potassium salt and 1 H NMR (500MHz, D 2 O, δppm) are listed in Table 1:

[0037] The physicochemical data of table 1 example 1-3 potassium salt of phosphate

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com