Ultrasonic wave rice immersion device and immersion method

An ultrasonic wave and rice technology, applied in the field of ultrasonic rice soaking device, can solve the problems affecting the quality of rice crackers, high investment in soaking equipment, long soaking time, etc., and achieve the effect of fast and uniform absorption of water, shortening soaking time, and shortening soaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Soaking of Northeast Japonica Rice:

[0029] The first step, at first quantitatively weigh 500kg Northeast japonica rice and carry out two washes for subsequent use.

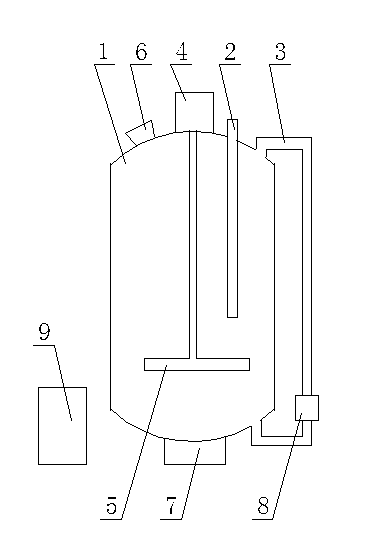

[0030] The second step is to weigh 550kg of soaking water according to the mass ratio of raw rice and soaking water 1:1.1, put the soaking water into the soaking tank 1 of the ultrasonic rice soaking device from the feed port 6, and then wash it twice The last 500kg northeast japonica rice is put into soaking tank body 1 by feed opening 6.

[0031] The 3rd step, when 500kg Northeast Japonica rice is put into soaking tank body 1, open stirring motor 4, and control the rotating speed of stirring paddle 5 at 30rpm, and start pneumatic diaphragm pump 8 simultaneously, so that the Northeast Japonica rice in soaking tank body 1 and Material circulation of soaking water achieves the purpose of evenly mixing Northeast japonica rice with soaking water.

[0032]In the fourth step, after the process ...

Embodiment 2

[0036] Embodiment 2: soaking of indica rice:

[0037] In the first step, 500kg of indica rice (Xinyou 369, early indica) was quantitatively weighed and washed twice for later use.

[0038] The second step is to weigh 500kg of soaking water according to the mass ratio of raw rice and soaking water 1:1, put the soaking water into the soaking tank 1 of the ultrasonic rice soaking device from the feed port 6, and then wash it twice The last 500kg indica rice is put into soaking tank body 1 by feed opening 6.

[0039] In the third step, when 500kg of indica rice is put into the soaking tank 1, the stirring motor 4 is turned on, and the rotating speed of the stirring paddle 5 is controlled at 25rpm, and the pneumatic diaphragm pump 8 is started at the same time, so that the indica rice in the soaking tank 1 is mixed with the soaking water. Material circulation to achieve the purpose of uniform mixing of indica rice and soaking water.

[0040] In the fourth step, after the indica r...

Embodiment 3

[0044] Embodiment 3: the soaking of brown rice:

[0045] The first step, at first quantitatively take 500kg of brown rice and carry out two washes and processes for subsequent use.

[0046] The second step is to weigh 450kg of soaking water according to the mass ratio of raw rice and soaking water 1:0.9, put the soaking water into the soaking tank 1 of the ultrasonic rice soaking device from the feed port 6, and then wash it twice The last 500kg brown rice is put into the soaking tank body 1 by the feed port 6.

[0047] In the third step, when 500kg of brown rice is put into the soaking tank 1, turn on the stirring motor 4, and control the rotating speed of the stirring paddle 5 at 20rpm, and start the pneumatic diaphragm pump 8 at the same time, so that the brown rice in the soaking tank 1 and the soaking water The material is circulated to achieve the purpose of uniform mixing of brown rice and soaking water.

[0048] In the fourth step, after the process of putting the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com