Preparation method for metallic oxide spherical cascade structure

A cascade structure, oxide technology, applied in oxide/hydroxide preparation, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve low pollution environment, time-consuming output, hydrothermal, hydrolysis The method and steps are complicated, and the equipment requirements are not high, the time required is short, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

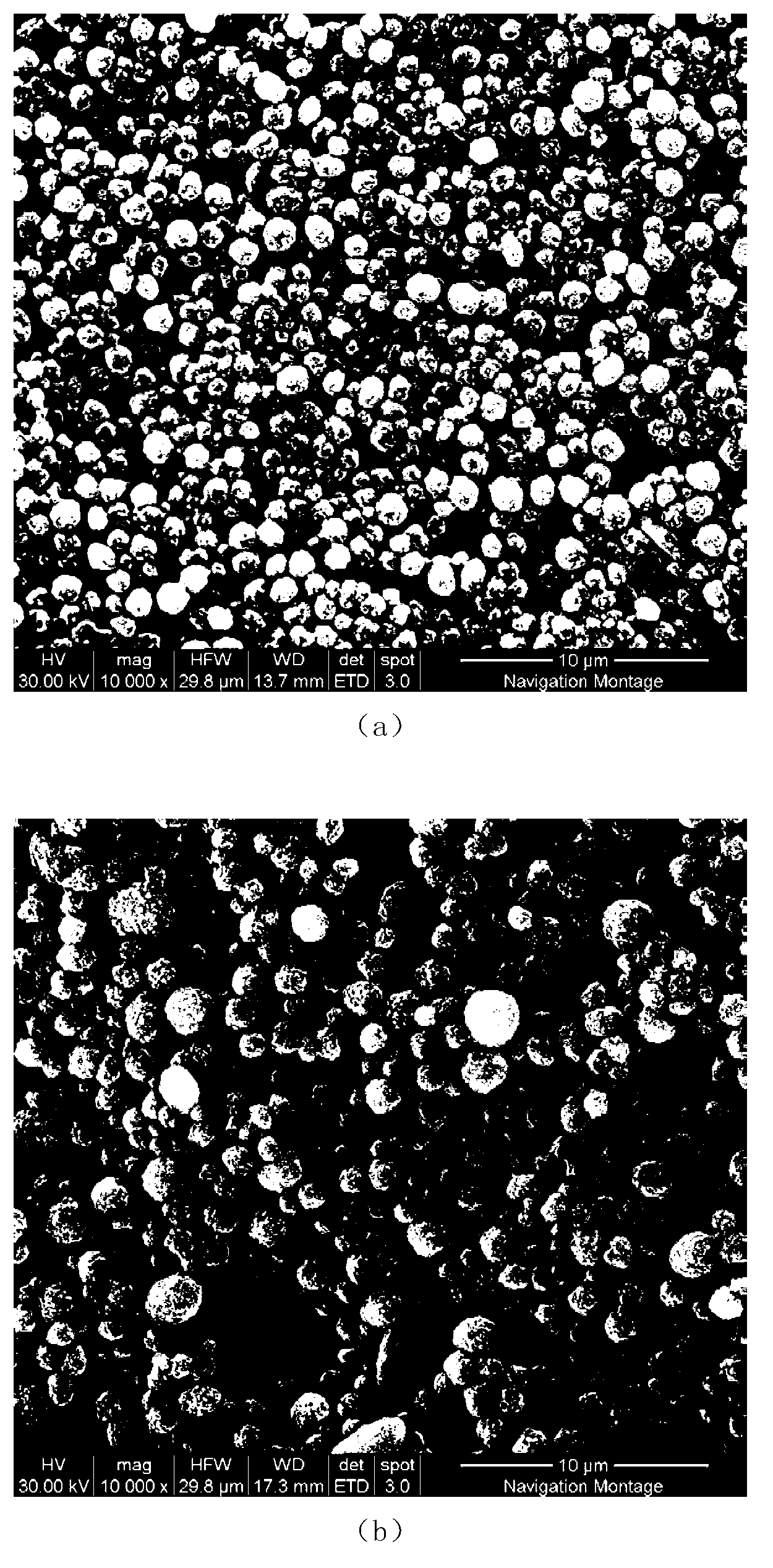

[0017] Mix titanium dioxide powder with a particle size of about 25 nanometers and polyethylene glycol with a molecular weight of 20,000 according to a mass ratio of 3:1 by ball milling to obtain a mixed powder of titanium dioxide and polyethylene glycol; use water as a solvent to prepare slurry material, after stirring evenly, use the coating method to coat the substrate; remove the organic matter through the sintering process to obtain a titanium dioxide spherical cascaded film, see figure 1 (a).

Embodiment 2

[0019] Mix titanium dioxide powder with a particle size of about 25 nanometers and polyethylene glycol with a molecular weight of 10,000 according to a mass ratio of 3:1 by ball milling to obtain a mixed powder of titanium dioxide and polyethylene glycol; use ethanol as a solvent to prepare slurry After stirring evenly, it is coated on the substrate to form a block; the organic matter is removed through the sintering process to obtain a block of titanium dioxide spherical cascade structure, see figure 1 (b).

Embodiment 3

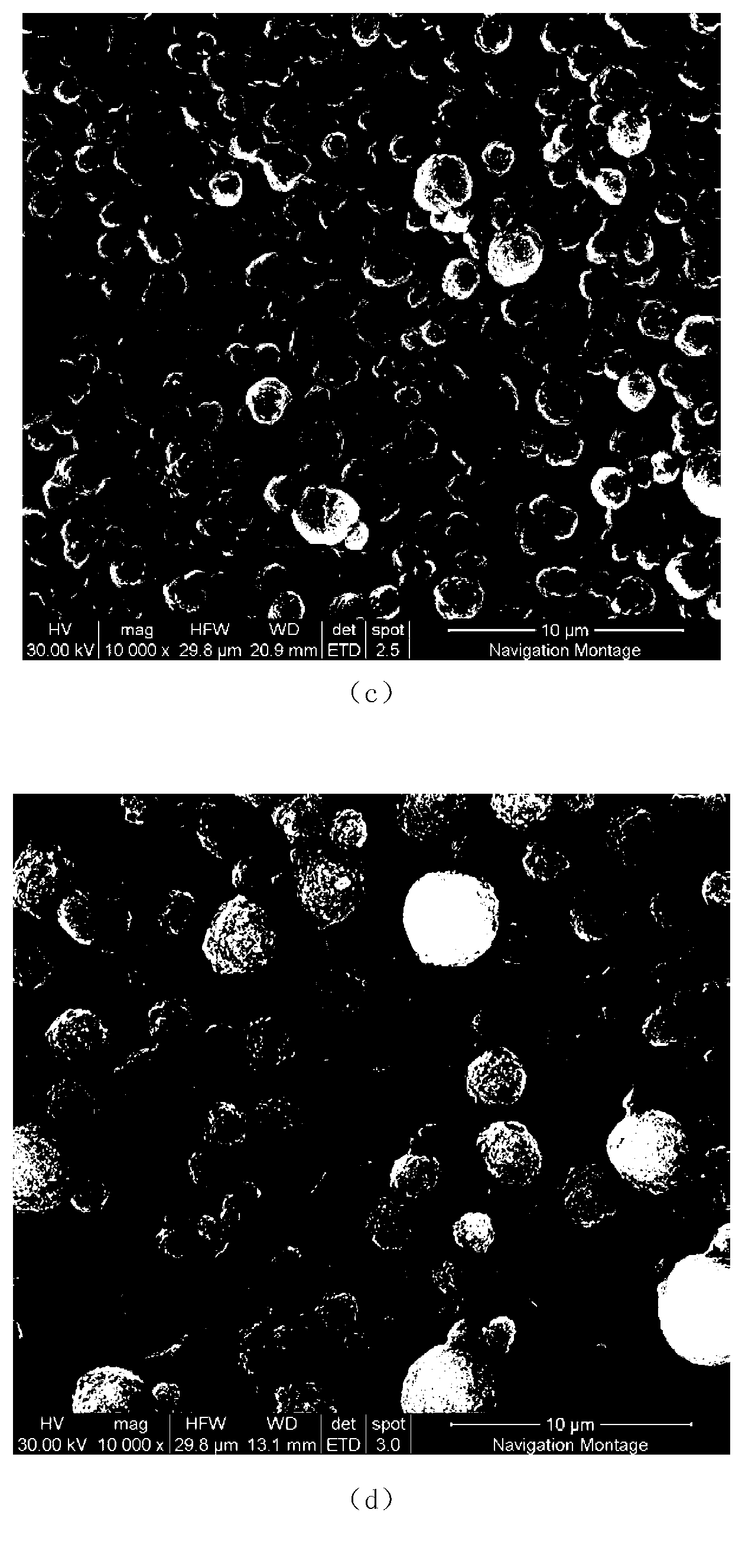

[0021] Mix titanium dioxide powder with a particle size of about 25 nanometers and polyethylene glycol with a molecular weight of 4000 according to a mass ratio of 3:1 by ball milling to obtain a mixed powder of titanium dioxide and polyethylene glycol; use water as a solvent to prepare slurry material, after stirring evenly, the method of spin coating is used to form a film on the substrate; the organic matter is removed by sintering process, and a titanium dioxide spherical cascade structure film is obtained, see figure 1 (c).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com