Erbium-ytterbium co-doped tungstate upconversion luminescent material, preparation method and application of material

A luminescent material and co-doping technology, applied in the field of luminescent materials in luminescence physics, to achieve the effects of stable luminescence performance, environmental friendliness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

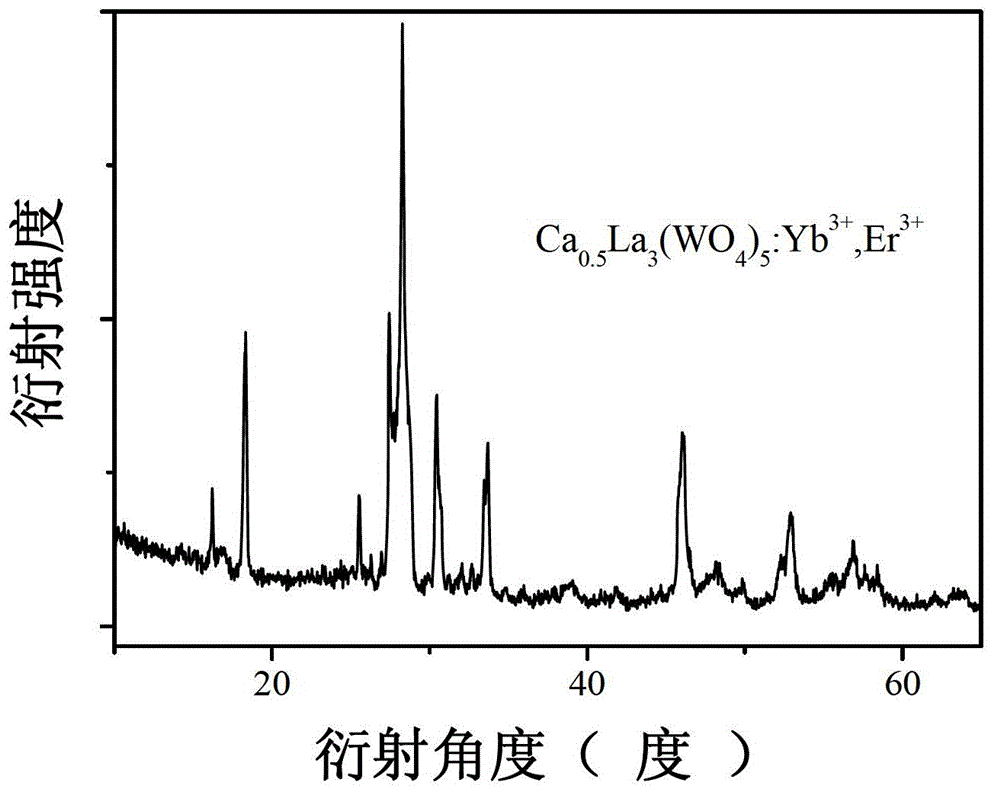

[0034] Preparation of Ca 0.5 La 2.7 Yb 0.2 Er 0.1 (WO 4 ) 5

[0035] According to the chemical formula Ca 0.5 La 2.7 Yb 0.2 Er 0.1 (WO 4 ) 5 The stoichiometric ratio of each element in is weighed separately: ytterbium oxide Yb 2 o 3 : 0.063 g, erbium oxide Er 2 o 3 : 0.031 g, calcium carbonate CaCO 3 : 0.08 g, tungsten oxide WO 3 : 1.86 g, lanthanum oxide La 2 o 3 : 0.71 g.

[0036] After grinding and mixing uniformly in an agate mortar, select the air atmosphere for the first sintering, the sintering temperature is 550 ° C, and the sintering time is 7 hours, then cool to room temperature, take out the sample, repeat the sintering operation, and perform the second sintering.

[0037] After the second sintering, the mixture was thoroughly mixed and ground again, and the third calcination was carried out in an air atmosphere at 750 °C for 9 hours, cooled to room temperature, and the samples were taken out. Then fully mix the mixture again and grind it evenl...

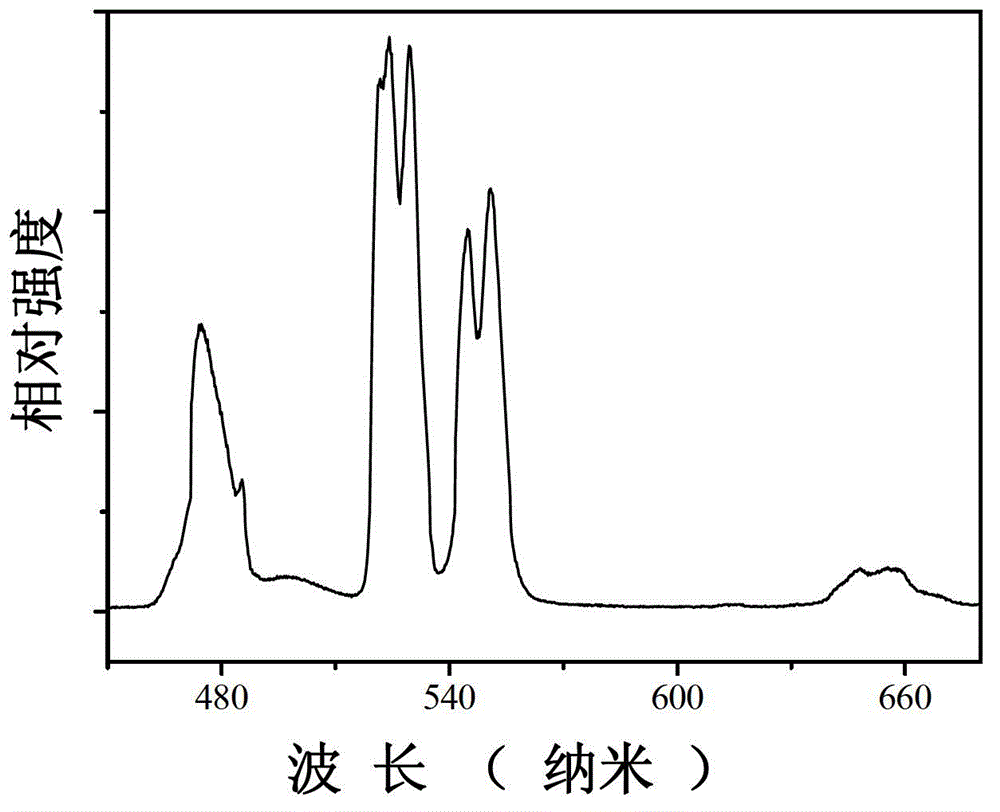

Embodiment 2

[0041] Preparation of Ca 0.5 La 2 Yb 0.7 Er 0.3 (WO 4 ) 5

[0042] According to the chemical formula Ca 0.5 La 2 Yb 0.7 Er 0.3 (WO 4 ) 5 The stoichiometric ratio of each element in is weighed separately: ytterbium oxide Yb 2 o 3 : 0.22 g, erbium oxide Er 2 o 3 : 0.092 g, Calcium Carbonate CaCO 3 : 0.08 g, tungsten oxide WO 3 : 1.86 g, lanthanum oxide La 2 o 3 : 0.52 g.

[0043] After grinding and mixing uniformly in an agate mortar, select the air atmosphere for the first sintering, the sintering temperature is 350 ℃, and the sintering time is 5 hours, then cool to room temperature, and take out the sample. The mixture was fully mixed and ground evenly again, and the second calcination was carried out at 800°C in an air atmosphere for 10 hours, cooled to room temperature, and the sample was taken out. Then fully mix the mixture again and grind it evenly. In the air atmosphere, it is calcined for the third time at 1000°C. The calcining time is 13 hours. Th...

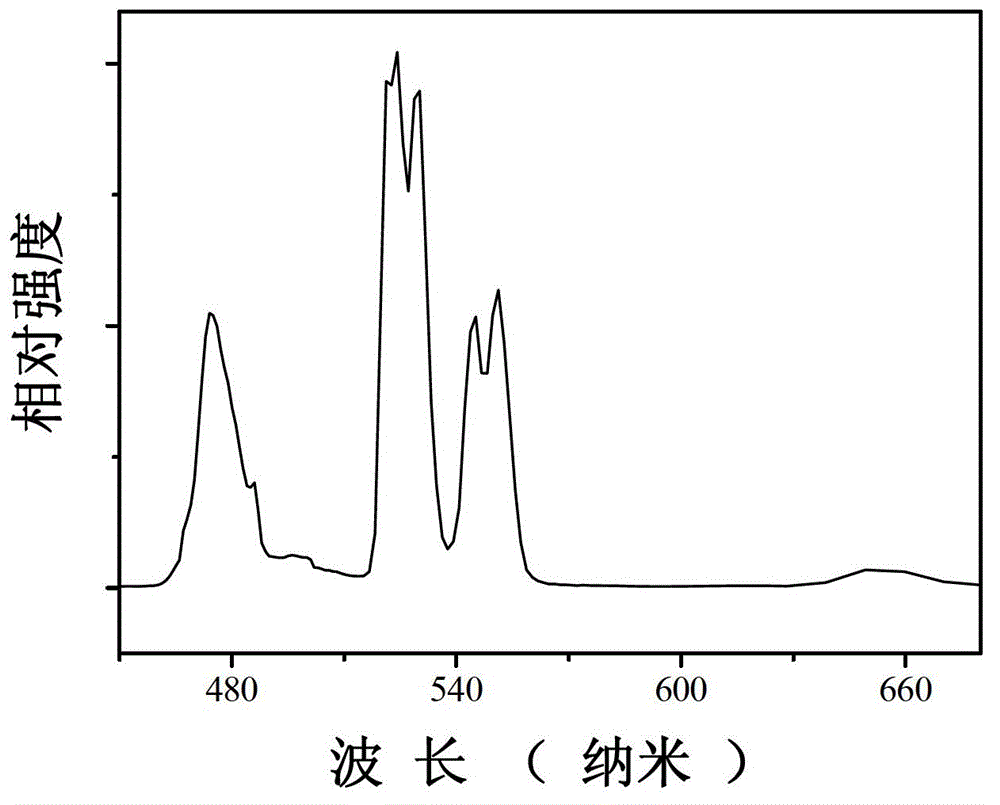

Embodiment 3

[0046] Preparation of Ca 0.5 wxya 1.5 Er 0.5 (WO 4 ) 5

[0047] According to the chemical formula Ca 0.5 wxya 1.5 Er 0.5 (WO 4 ) 5 The stoichiometric ratio of each element in is weighed separately: ytterbium oxide Yb 2 o 3 : 0.98 g, erbium oxide Er 2 o 3 : 0.32 g, Calcium Carbonate CaCO 3 : 0.08 g, tungsten oxide WO 3 : 1.86 g, lanthanum oxide La 2 o 3 : 0.54 g.

[0048] After grinding and mixing uniformly in an agate mortar, select the air atmosphere for the first sintering, the sintering temperature is 250 °C, the sintering time is 4 hours, then cool to room temperature, take out the sample and grind it evenly, repeat the sintering operation for the second time sintering.

[0049] Cool to room temperature, mix and grind the mixture thoroughly again, and perform the third calcination in air atmosphere at 880°C for 5 hours, cool to room temperature, and take out the sample. Mix the mixture thoroughly again and grind it evenly. In the air atmosphere, carry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com