Saline-alkali soil modifier and preparation method and application thereof

A technology of improver and saline-alkali land, applied in the field of saline-alkali land improver and its preparation and application, can solve the problems of high cost, complex production process, and inability to be popularized in a large area, and achieve low application cost, simple production method, and increase production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: produce 100 kilograms of products by weight ratio:

[0019] 23% of biochar, 55% of phosphogypsum, 15% of ammonium humate, 5% of urea, and 2% of citric acid were fully mixed in proportion to obtain a mixture;

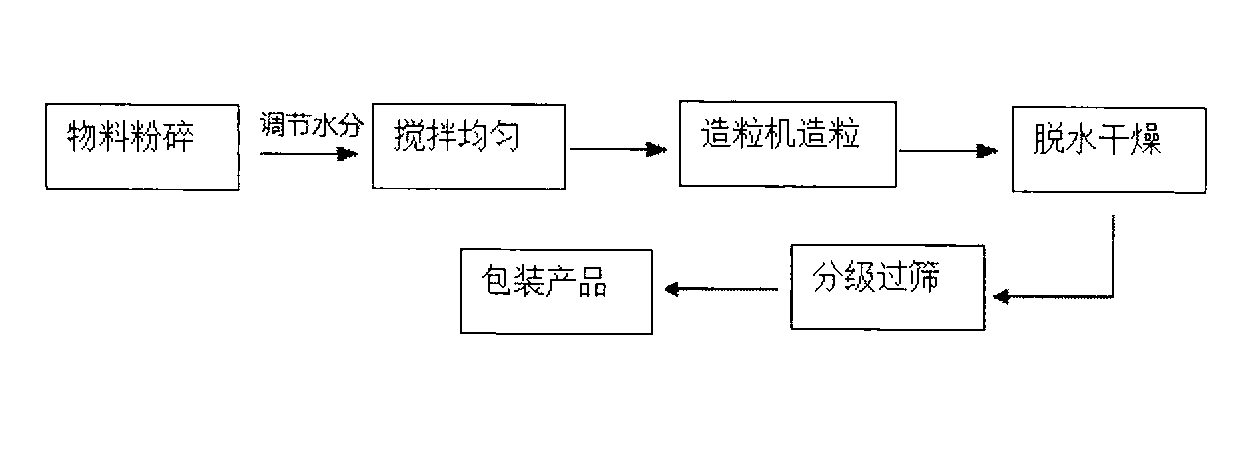

[0020] Then add the mixture to 30% water of the mass of the material and mix evenly, enter the conventional granulator for granulation, and then carry out drying and dehydration. The moisture content of the dehydrated material is 3%, grading, sieving, and packaging to obtain the saline-alkaline soil improver;

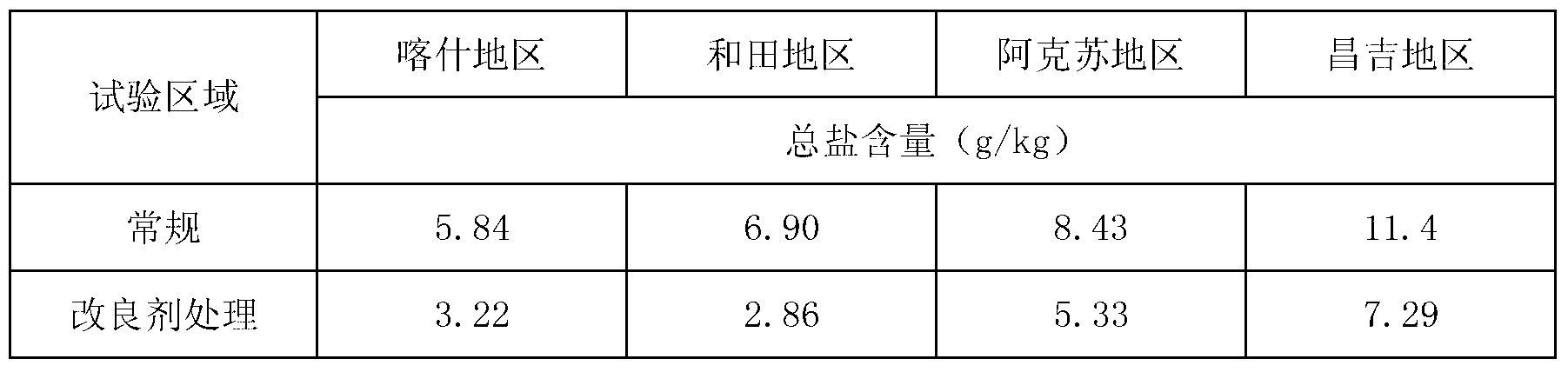

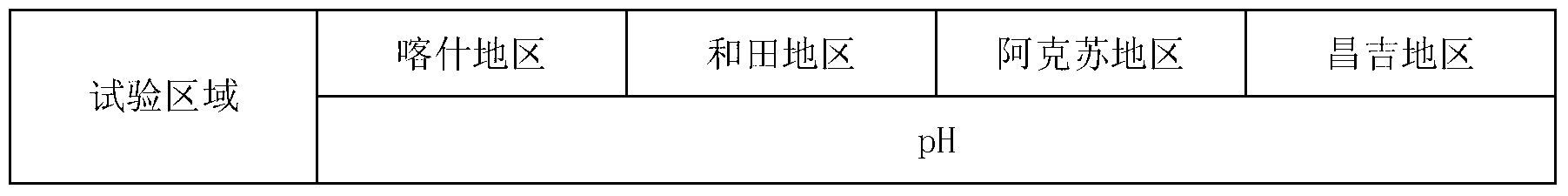

[0021] When in use, according to the total soil salt content of 0.4-0.6%, apply 100-200kg of improver per mu; if the total soil salt is 0.6-1.2%, apply 200-500kg of improver per mu.

Embodiment 2

[0022] Embodiment 2: produce 100 kilograms of products:

[0023] 50% of biochar, 34% of phosphogypsum, 10% of ammonium humate, 5% of urea, and 1% of citric acid were fully mixed in proportion to obtain a mixture;

[0024] Add the mixture to 35% water of the mass of the material and mix it evenly. After being granulated in a conventional granulator, it is dried and dehydrated. The moisture content of the dehydrated material is 5%, graded, sieved, and packaged to obtain a saline-alkaline soil improver;

[0025] When in use, according to the total soil salt content of 0.4-0.6%, apply 100-200kg of improver per mu; if the total soil salt is 0.6-1.2%, apply 200-500kg of improver per mu.

Embodiment 3

[0026] Embodiment 3: produce 100 kilograms of products:

[0027] 60% of biochar, 20% of phosphogypsum, 15% of ammonium humate, 3.5% of urea, and 1.5% of citric acid were fully mixed in proportion to obtain a mixture;

[0028] Add the mixture to 38% water of the mass of the material and mix it evenly. After entering the conventional granulator for granulation, it is dried and dehydrated. The moisture content of the dehydrated material is 8%. It is graded and sieved, and packaged to obtain the saline-alkaline soil improver;

[0029] When in use, according to the total soil salt content of 0.4-0.6%, apply 100-200kg of improver per mu; if the total soil salt is 0.6-1.2%, apply 200-500kg of improver per mu.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com