Preparation method of wheat germ instant powder with long shelf life

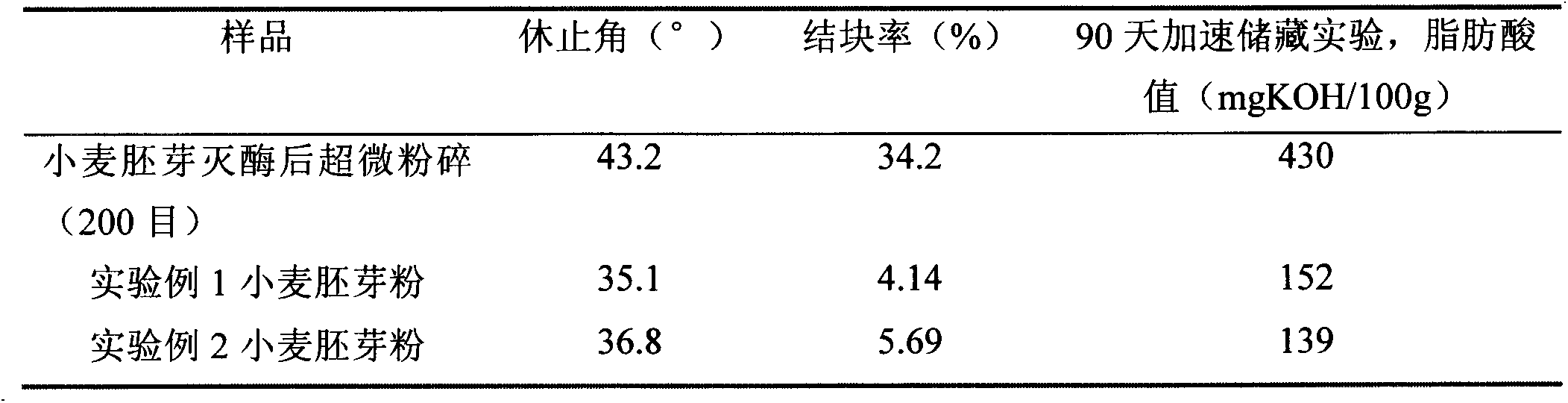

A wheat germ, shelf life technology, applied in the field of food processing, can solve the problems of easy re-aggregation, lower brewing quality of wheat germ powder, difficult storage of wheat germ powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] Example 1. The industrial production of instant wheat germ nutritional powder includes the following steps in sequence:

[0007] (1) Pass 300 kg of fresh wheat germ through a 40 mesh and 80 mesh vibrating sieve to remove impurities such as bran and flour mixed in the wheat germ.

[0008] (2) Put the wheat germ into the tunnel-type atmospheric steaming treatment: the material layer is about 0.5cm thick and steamed for 15 minutes; then the wheat germ and water are mixed and stirred at 1:7.5 for 20 minutes, and then crushed twice with a colloid mill, then The wheat germ suspension was pumped into the enzyme reaction tank and stirred for 3 minutes to make the wheat germ suspension uniform.

[0009] (3) Adjust the pH of the wheat germ solution in the enzyme reaction tank to 4.5 with a 0.4mol / L solution prepared with food grade citric acid. Steam the heating coil in the enzyme reaction tank to raise the temperature of the wheat germ solution to 55°C.

[0010] (4) At the same time, a...

Embodiment 2

[0013] Example 2. The laboratory preparation of wheat germ nutritional powder includes the following steps in sequence:

[0014] (1) Pass 5 kg of fresh wheat germ through a 40 mesh and 80 mesh vibrating sieve to remove impurities such as bran and flour mixed in the wheat germ.

[0015] (2) Put the wheat germ in a steamer for steaming treatment: the material layer is about 0.5cm thick and steamed for 15 minutes; then the wheat germ and water are mixed and stirred at 1:7.5 for 10 minutes, crushed twice with a colloid mill, and then The wheat germ suspension was poured into the enzyme reaction tank and stirred for 3 minutes to make the wheat germ suspension uniform.

[0016] (3) Adjust the pH of the wheat germ solution in the enzyme reaction tank to 4.5 with a 0.4mol / L solution prepared with food grade citric acid. The heating interlayer of the enzyme reaction tank is added with heat-conducting water to raise the temperature of the wheat germ solution to 55°C.

[0017] (4) At the same t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fatty acid value | aaaaa | aaaaa |

| Fatty acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com