3D-printing fast forming method of nano composite degradable bone repair material

A nano-composite, three-dimensional printing technology, applied in bone implants, medical science, prostheses, etc., can solve the problems of insufficient mechanical strength and strength retention time, inability to synthesize bone repair materials, and acid degradation products, etc. Fast speed, good effect, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

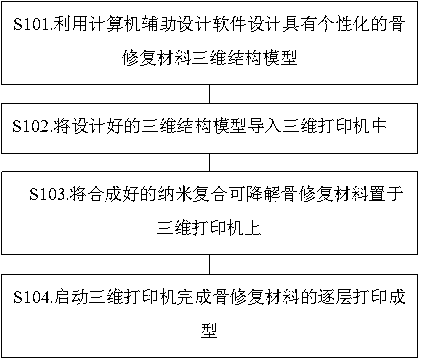

[0036] Such as figure 1As shown, it is a flow chart of a specific embodiment of a preparation method for three-dimensional printing rapid prototyping of a nanocomposite degradable bone repair material in the present invention. see figure 1 The specific steps of the preparation method of a nanocomposite degradable bone repair material for three-dimensional printing rapid prototyping in this embodiment include:

[0037] S101. Using computer-aided design software to design a personalized three-dimensional structure model of the bone repair material; wherein, the computer-aided design software can use solidworks software, and of course other software that can realize the above functions can also be used.

[0038] S102. Import the designed 3D structural model into the 3D printer;

[0039] S103. placing the synthesized nanocomposite degradable bone repair material on the three-dimensional printer;

[0040] S104. Start the three-dimensional printer to complete the layer-by-layer p...

Embodiment 2

[0048] In this example, polylactic acid is used as the degradable bone repair polymer, and a composite material of polylactic acid and nano-hydroxyapatite is prepared by melt blending as follows:

[0049] Nano-hydroxyapatite particles are added to polylactic acid, blended under the condition of 120-150°C higher than the glass transition temperature of polylactic acid, and the nano-hydroxyapatite particles are compounded into the polylactic acid matrix by mechanical force.

Embodiment 3

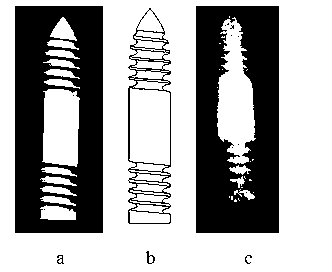

[0051] This embodiment realizes the preparation of a simple solid bone screw, and the specific steps are as follows:

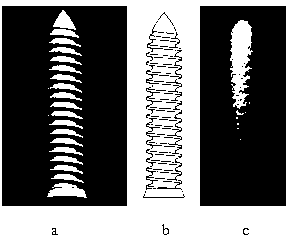

[0052] (1) Design of 3D structure of simple solid bone screw

[0053] Using the computer-aided design software solidworks to design a simple solid bone screw three-dimensional structure model, such as figure 2 As shown in a; during the design, the three-dimensional structure model of the simple solid bone screw is individually configured. For example, the parameters of the simple solid bone screw are set as follows: the screw diameter is designed to be 8mm, the screw length is designed to be 40mm, the pitch is designed to be 2mm, and the thread depth Designed to be 1.5mm.

[0054] Save the 3D structure model of the designed simple solid bone screw as a file in STL format, such as figure 2 As shown in b, it is a schematic diagram of a simple solid bone screw in the engineering drawing format displayed in the STL format file.

[0055] (2) Printing of simple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com