Preparation method of periodic mesoporous organosilica (PMO) magnetic ball Fe3O4@PMO material

A technology of mesoporous organosilicon and organosilicon source is applied in the preparation of microspheres, the magnetic properties of inorganic materials, and the preparation of microcapsules. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 0.2g Fe 3 o 4 100nm nanoparticles were put into a 1000mL three-neck flask, and 600mL of 0.1M hydrochloric acid (HCl) solution was added to sonicate for 30min. Magnet recovery, repeated washing 3 times to remove residual hydrochloric acid. Add 0.5g cetyltrimethylammonium bromide (CTAB), 7mL 0.5M sodium hydroxide (NaOH) and 240mL water (H 2 O), stirring manually every 5min, ultrasonic 30min.

[0025] (2) Move the three-necked flask in step (1) to an 80°C oil bath, and mechanically stir at 480r / min for 10min to make the temperature of the solution in the three-necked flask reach 80°C.

[0026] (3) Increase the mechanical stirring speed to 600r / min, slowly add 2.16mL of 1,4-bis(triethoxysilyl)benzene (BTEB) dropwise into the three-necked flask, and continue the mechanical stirring for 2h.

[0027] (4) Pour the product obtained in step (3) into a 500mL beaker, attach a magnet to the beaker, let it stand for 5min, and pour off the reaction solution. Repeat 6 w...

Embodiment 2

[0032] Weigh 1.2g Fe 3 o 4 0.2g Fe in alternative embodiment one step (1) 3 o 4 , reduce the stirring speed, and keep other conditions unchanged.

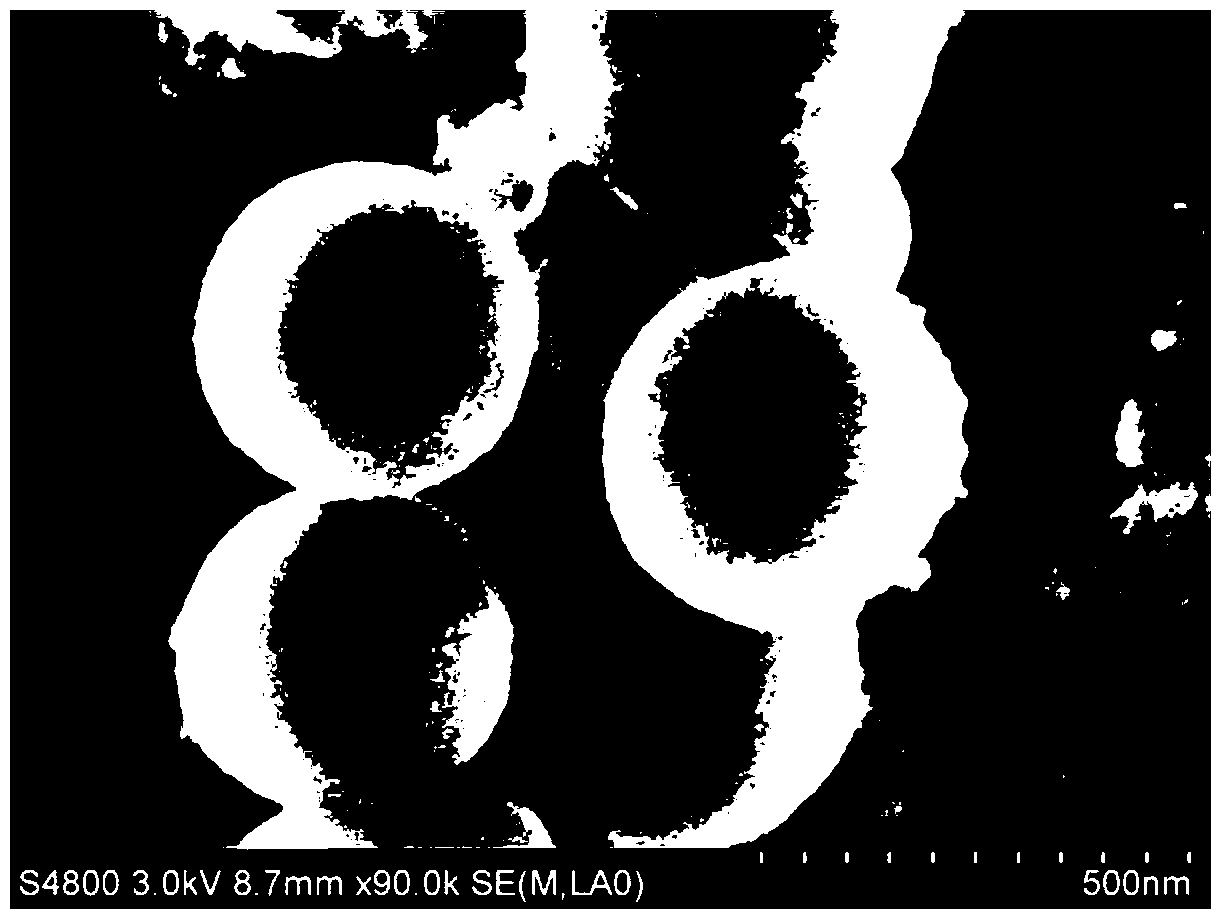

[0033] image 3 For the Fe prepared by Example 2 of the present invention 3 o 4 Scanning electron microscope (SEM) picture of PMO magnetic ball material, by figure 1 It can be seen that the prepared Fe 3 o 4 The agglomeration of PMO magnetic ball materials is relatively severe, and the diameters are different, the small one is about 300nm, and the large one is about 700nm.

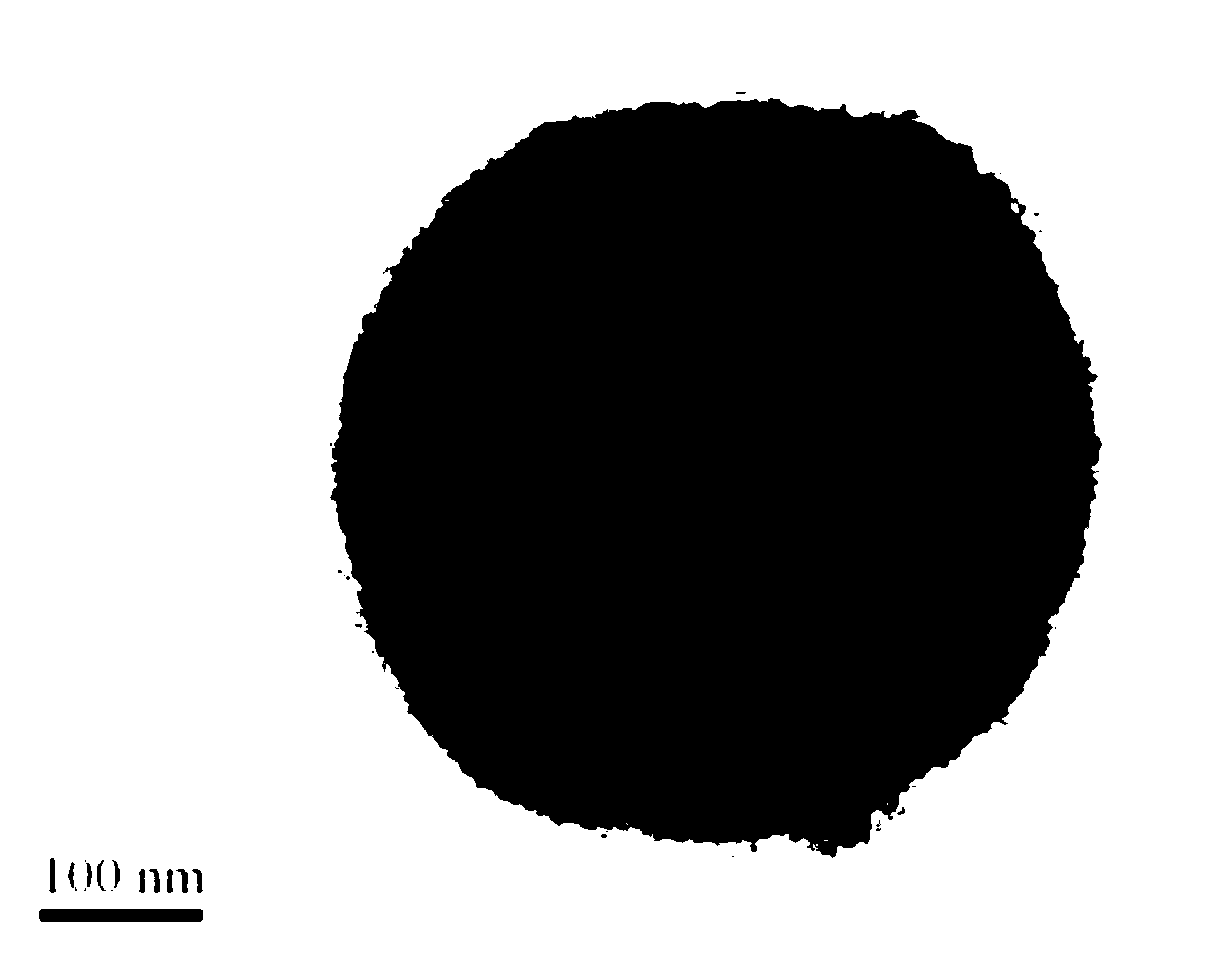

[0034] figure 2 For the Fe prepared by Example 2 of the present invention 3 o 4 Transmission electron microscopy (TEM) of PMO magnetic ball material. Depend on figure 2 It can be seen that the prepared Fe 3 o 4 The agglomeration of iron tetroxide wrapped by PMO magnetic ball material is relatively strong, and the wrapping of phenyl silicon source is also irregular.

Embodiment 3

[0036] Use 2.16mL 1,2-bis(triethoxysilyl)ethane (BTE) 1,4-bis(triethoxysilyl)benzene (BTEB) in step (3) of Example 1, other Conditions remain the same

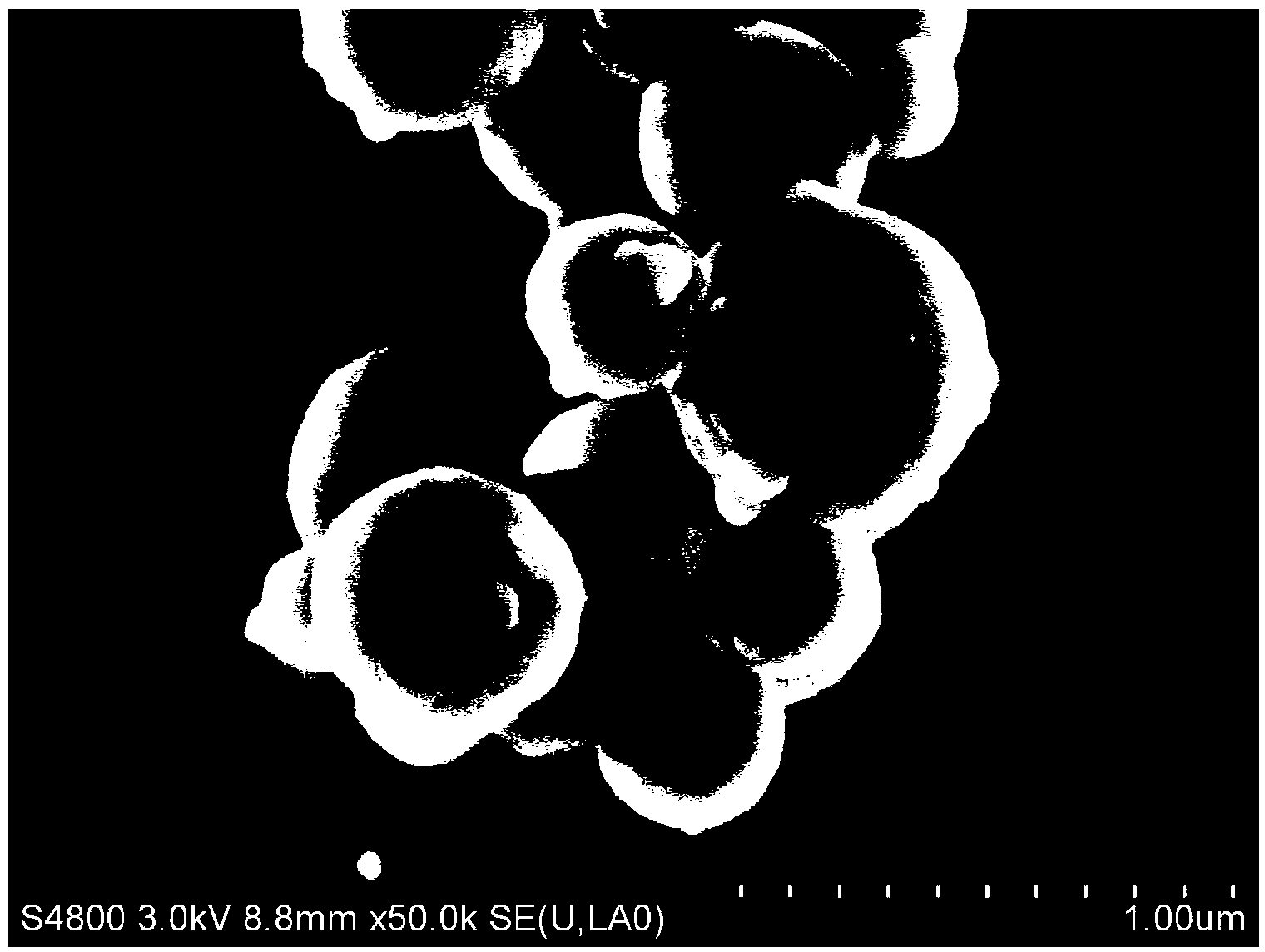

[0037] Figure 5 Fe prepared for Example 3 of the present invention 3 o 4 Scanning electron microscope (SEM) picture of PMO magnetic ball material, by image 3 It can be seen that the prepared Fe 3 o4 The dispersion of PMO magnetic ball material is relatively uniform, and the diameter is about 450nm.

[0038] Figure 6 Fe prepared for Example 3 of the present invention 3 o 4 Transmission electron microscopy (TEM) of PMO magnetic ball material. Depend on figure 2 It can be seen that the prepared Fe 3 o 4 The PMO magnetic ball material is evenly wrapped, and the wall thickness is about 50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com