High-speed aircraft large-area interlayer heat protection and insulation structure and forming method thereof

A high-speed aircraft and molding method technology, applied in the direction of layered products, fuselage insulation, etc., can solve the problems of limited use, poor bearing performance, low mechanical properties of aerogel composite materials, etc., to avoid damage, process stability, and benefit The effect of promotion and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

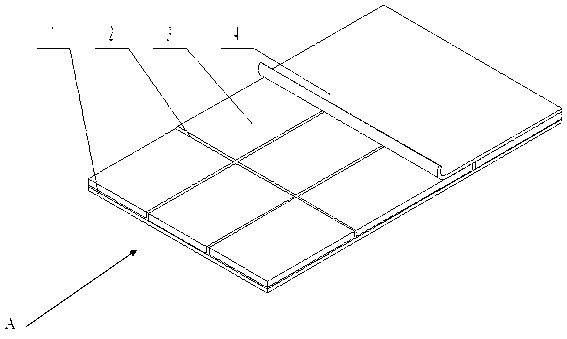

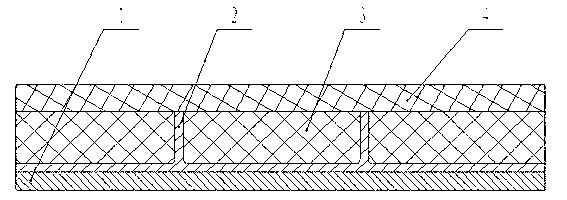

[0061] The high-speed aircraft has a large-area sandwich anti-heat insulation structure, and the grid rib support layer and the outer skin heat protection layer are made of fiber-reinforced composite materials composed of high-silica fiber yarn, fabric and phenolic resin; among them, the grid rib support layer The thickness of the inner skin is 2mm, the height of the ribs of the grid ribs is 10mm, the cross-sectional width of the ribs is 2mm, the shape of the grid surrounded by the ribs is rectangular, and its area is 100×200mm; the heat insulation layer is made of carbon dioxide Silica airgel composite material, wherein, the thickness of the silica airgel composite material is the same as the rib height of the grid ribs; the thickness of the outer skin heat-proof layer is 5mm.

[0062] The forming method of the above-mentioned sandwich anti-insulation structure, the specific steps are as follows:

[0063] 1) Select high-silica fiber yarn and high-silica fiber fabric as high-t...

example 2

[0070] The interlayer anti-insulation structure and the forming method of the anti-insulation structure of the present invention are similar to Example 1, and the same steps will not be repeated. The differences are:

[0071] The high-temperature-resistant fiber yarn and fabric selected in the grid rib support layer 2 and the outer skin heat-proof layer 4 are all quartz fibers, and the ablation-resistant resin is selected from modified phenolic resin; the thickness of the inner skin in the grid rib support layer 2 is 1mm; the thickness of the outer skin heat-proof layer is 4mm.

[0072] The forming method of the sandwich anti-insulation structure is the same as that of Example 1, and will not be repeated here. The differences are:

[0073] The high-temperature-resistant fiber in step 1) is made of quartz fiber yarn and quartz fiber fabric, and the ablation-resistant resin is selected as a modified phenolic resin as a raw material for standby;

[0074] In step 2), the base o...

example 3

[0080] The interlayer anti-insulation structure and the forming method of the anti-insulation structure of the present invention are similar to Example 1, and the same steps will not be repeated. The differences are:

[0081] The grid rib support layer 2 and the outer skin heat-proof layer 4 are mixed resin composite materials composed of quartz fiber reinforced polysilazane and benzoxazine. The thickness of the inner skin in the grid rib support layer 2 is 3mm. The rib height of the rib is 12mm; the thickness of the outer skin heat-proof layer is 7mm.

[0082] The forming method of the sandwich anti-insulation structure is the same as that of Example 1, and will not be repeated here. The differences are:

[0083] Step 1) Quartz fiber yarn and quartz fiber fabric are selected as medium and high-temperature resistant fibers; mixed polysilazane resins are used as raw materials for ablation-resistant resin;

[0084] In step 2), the base of the metal bearing structure is cleane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com