Process and device for electric cracking catalytic oxidation for petroleum drilling wastewater

A catalytic oxidation and oil drilling technology, applied in mining wastewater treatment, oxidized water/sewage treatment, water aeration, etc., can solve the problems of long residence time in the electrolysis process, poor effluent quality, weak oxidation ability, etc., and achieve improved electrolytic oxidation Reducing ability, short residence time, and the effect of reducing equipment energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

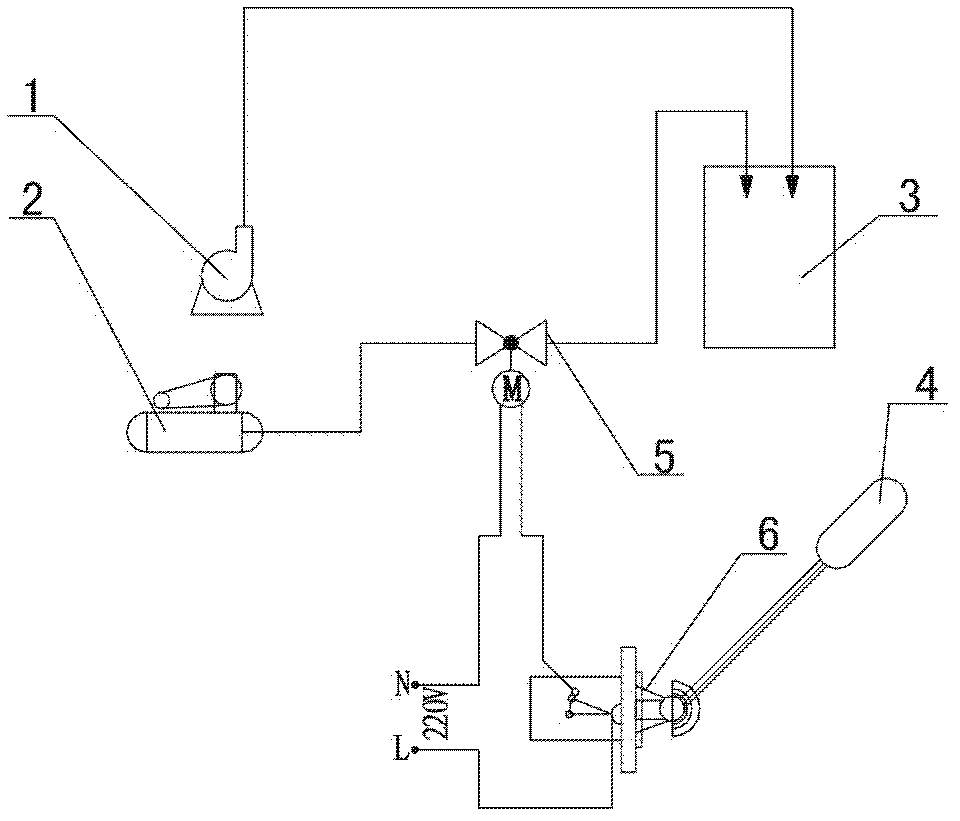

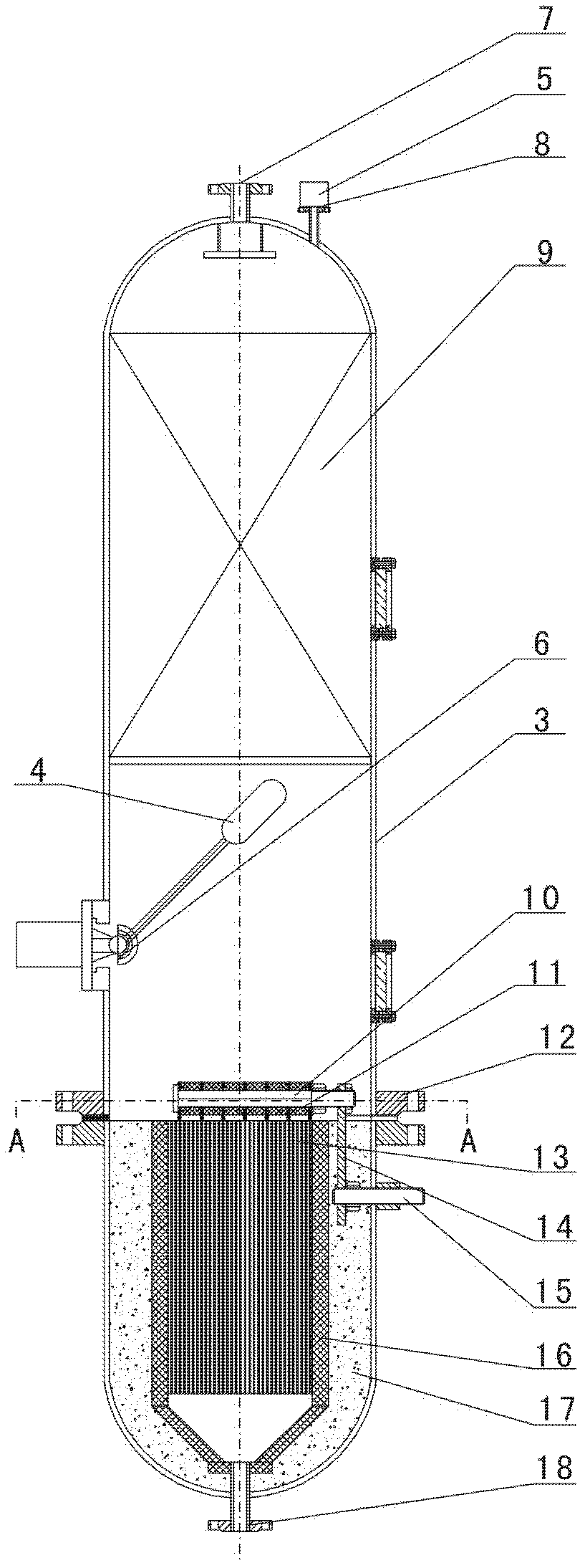

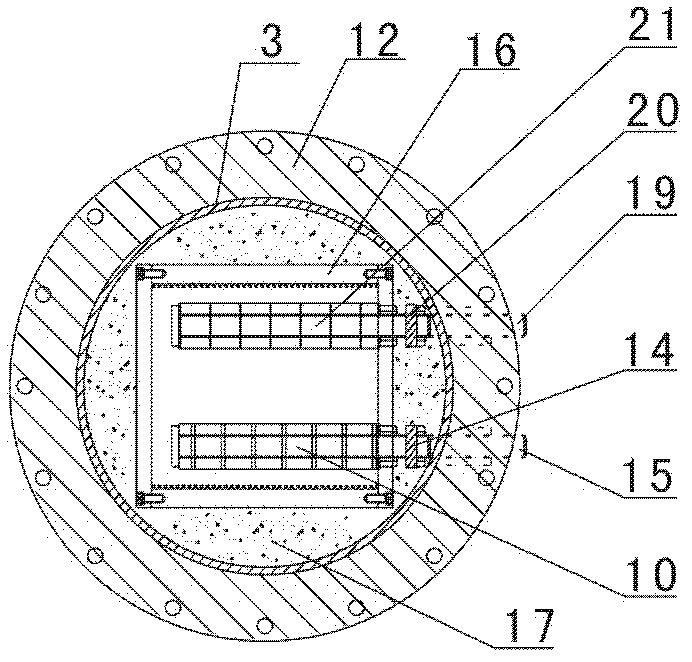

[0031] combine figure 1 and figure 2 The electrolytic catalytic oxidation process of petroleum drilling wastewater according to the present invention includes a gel breaking process, a centrifugal separation process, an electrolytic catalytic redox process and a filtering process, the gel breaking process is the first process, and the centrifugal separation process is the second process. The cracking catalytic redox process is the third process, and the filtering process is the fourth process; wherein, the electrolytic catalytic redox process is carried out in a high-pressure sealed reaction tank 3, and the pressure in the sealed reaction tank 3 is 0.2-0.5Mpa; In the catalytic redox process, the pressure in the sealed reaction tank 3 is realized by delivering high-pressure air to the sealed reaction tank 3 through the air compressor 2; the electrode plate 13 is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com