Propargyl ether resin with main chain containing pyridine ring aromatic bisphenol-type terminal and preparation method thereof

A pyridine ring aromatic, terminal propargyl ether technology, applied in the field of high temperature resistant resin, to achieve the effects of good fluidity, high yield and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

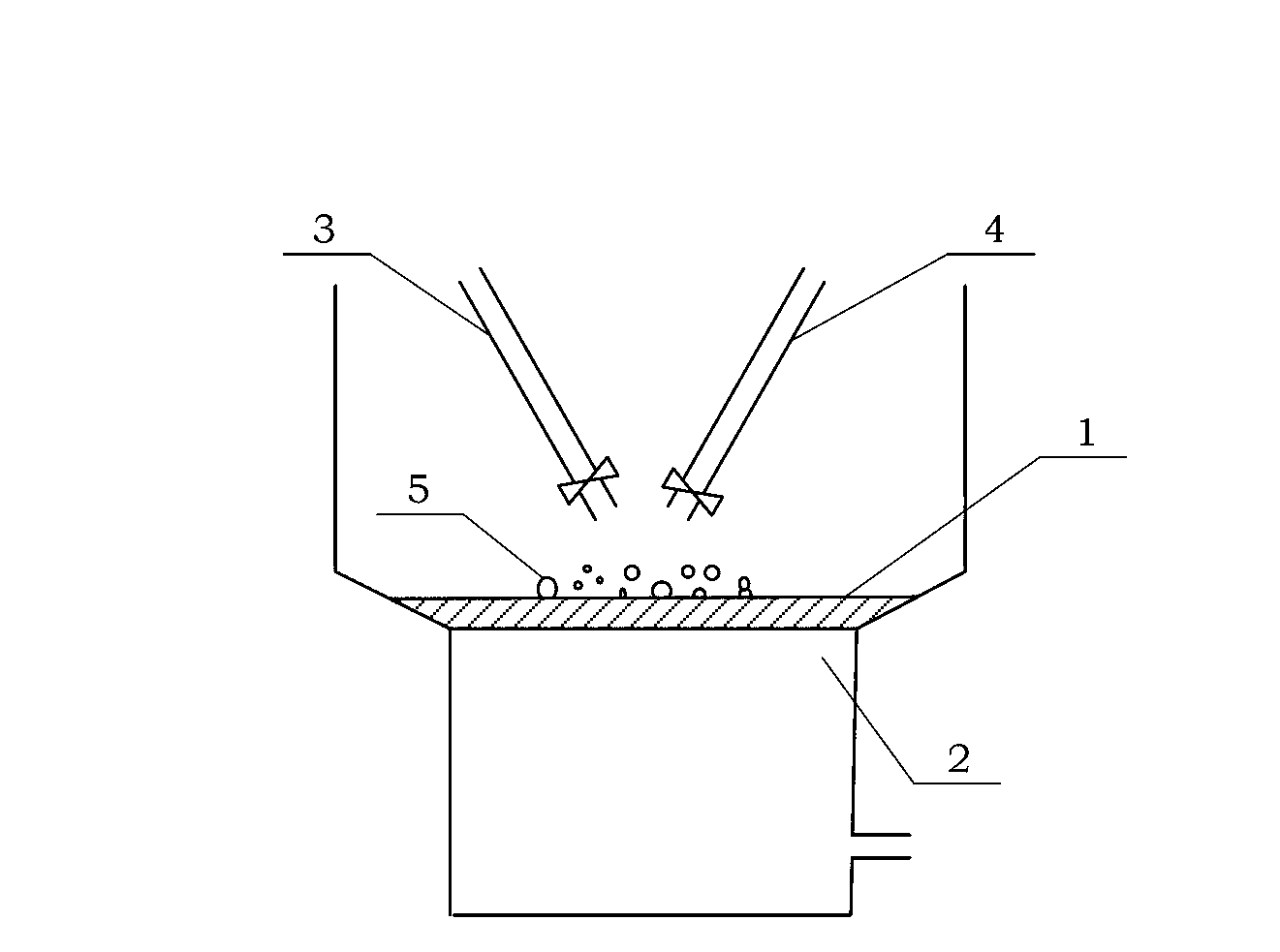

Method used

Image

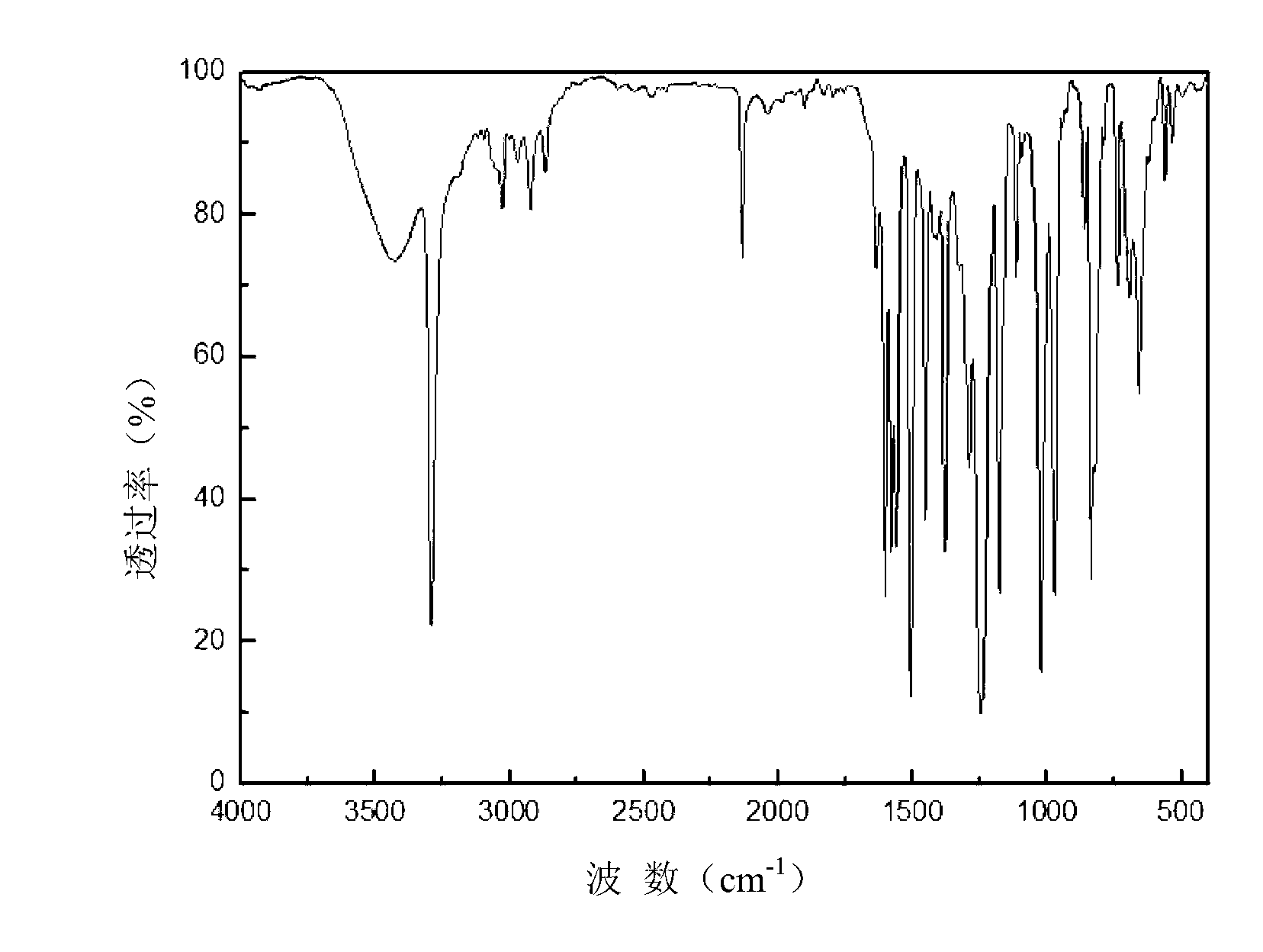

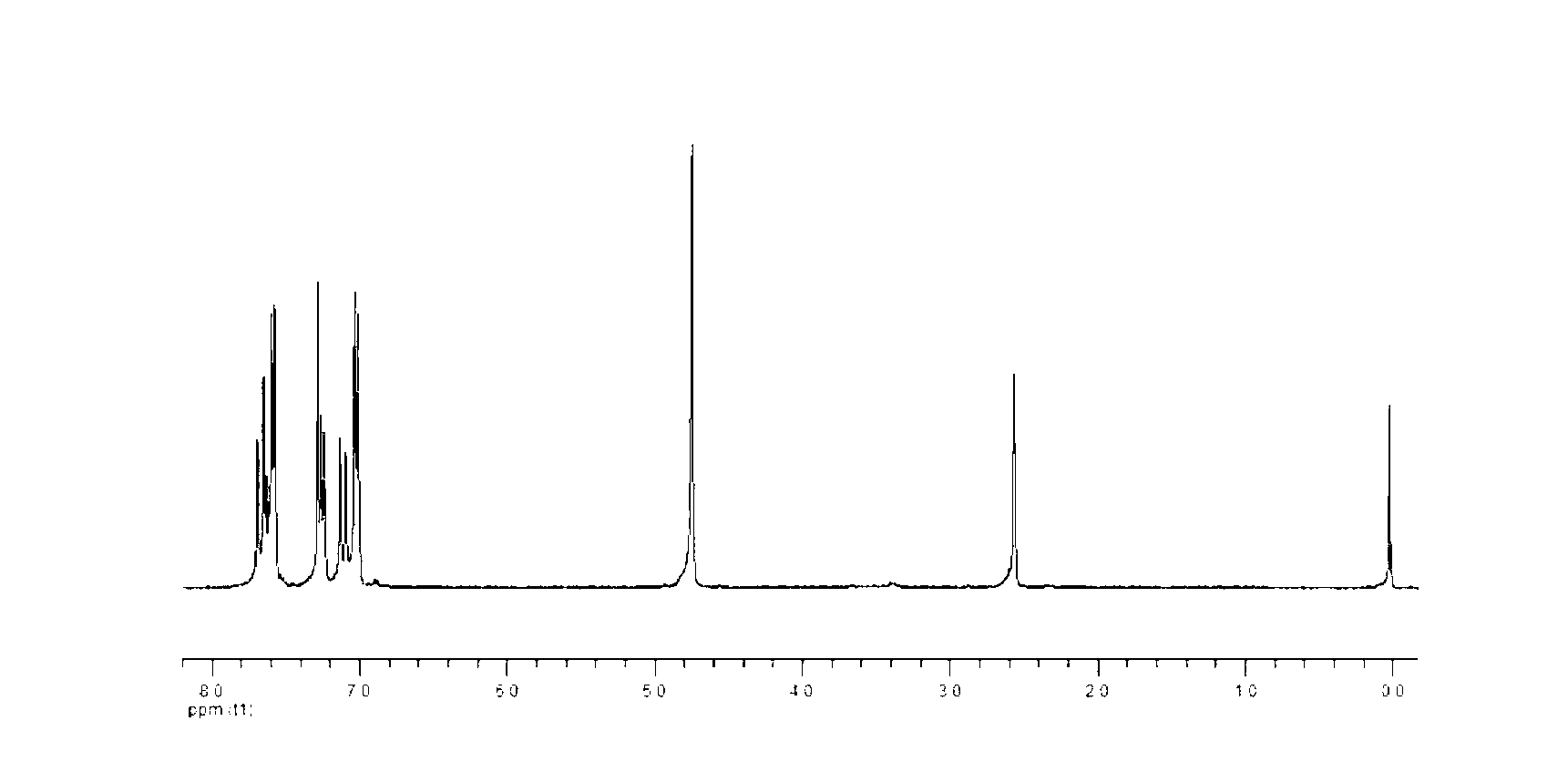

Examples

Embodiment 1

[0068] 2,6-bis(4-propargyl-oxy-styryl)pyridine is prepared by phase transfer catalytic reaction method, the specific preparation steps are as follows:

[0069] (A) Prepare an aqueous sodium hydroxide solution with a concentration of 20% by mass;

[0070] (B) Mix 2,6-bis(4-hydroxystyryl)pyridine, aqueous sodium hydroxide solution and tetrabutylammonium bromide to obtain a mixed solution;

[0071] Dosage: Add 1000 mL of sodium hydroxide aqueous solution and 0.1 mol of tetrabutylammonium bromide to 1mol of 2,6-bis(4-hydroxystyryl)pyridine;

[0072] The structural formula of the 2,6-bis(4-hydroxystyryl)pyridine is as shown in formula 3:

[0073] Formula 3

[0074] In formula 3, HO is a hydroxyl group, OH is a hydroxyl group, the hydroxyl group is at the para position of the vinyl HCHC, A is the vinyl HCHC; Y is hydrogen.

[0075] The structure of Formula 3 in Example 1 can be prepared according to the method disclosed in the "NEW STYRYLPWRIDINE-BASED POLYESTERS AND POLYURETHANES" document. ...

Embodiment 2

[0105] The phase transfer catalytic reaction method is used to prepare 2,6-bis(4-propargyl-oxy-benzoyl)pyridine. The specific steps are as follows:

[0106] (A) Prepare an aqueous potassium hydroxide solution with a concentration of 15% by mass;

[0107] (B) Mix 2,6-bis(4-hydroxybenzoyl)pyridine, potassium hydroxide aqueous solution and benzyltrimethylammonium bromide to obtain a mixed solution;

[0108] Dosage: Add 1500 mL of potassium hydroxide aqueous solution and 0.12 mol of benzyltrimethylammonium bromide to 1mol of 2,6-bis(4-hydroxybenzoyl)pyridine;

[0109] The structural formula of the 2,6-bis(4-hydroxybenzoyl)pyridine is as shown in formula 5:

[0110] Formula 5

[0111] In formula 5, HO is a hydroxyl group, OH is a hydroxyl group, and a hydroxyl group is at a carbonyl group. The para position, A is the carbonyl group Y is hydrogen.

[0112] The structure of Formula 5 in Example 2 can be prepared according to the method disclosed in the document "Synthesis and Performance Rese...

Embodiment 3

[0142] The phase transfer catalytic reaction method is used to prepare 4-chloro-2,6-bis(4-propargyl-oxy-styryl)pyridine. The specific steps are as follows:

[0143] (A) Prepare an aqueous solution of sodium hydroxide with a concentration of 30% by mass;

[0144] (B) Combine 4-chloro-2,6-bis(4-hydroxystyryl)pyridine, aqueous sodium hydroxide and tetraethylammonium bromide to obtain a mixed solution;

[0145] Dosage: 500mL of sodium hydroxide aqueous solution and 0.008mol of tetraethylammonium bromide are added to 1mol of 4-chloro-2,6-bis(4-hydroxystyryl)pyridine;

[0146] The structural formula of the 4-chloro-2,6-bis(4-hydroxystyryl)pyridine is as shown in formula 7:

[0147] Formula 7

[0148] In formula 7, HO is a hydroxyl group, OH is a hydroxyl group, and the hydroxyl group is at the para position of vinyl-HC=HC-, A is vinyl*HC=HC-, and Y is chlorine.

[0149] The structure of Formula 7 in Example 3 can be prepared according to the method disclosed in the "NEW STYRYLPWRIDINE-BASED PO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com