Sensing device of a fluorescent explosive detector

A sensing device and explosives technology, applied in the field of fluorescent explosives detection, can solve the problems of affecting the sensitivity of the instrument, inconvenient installation, fragile sensing film, etc., to ensure uniformity and real-time performance, and avoid contamination or damage , Improve the effect of sensitivity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

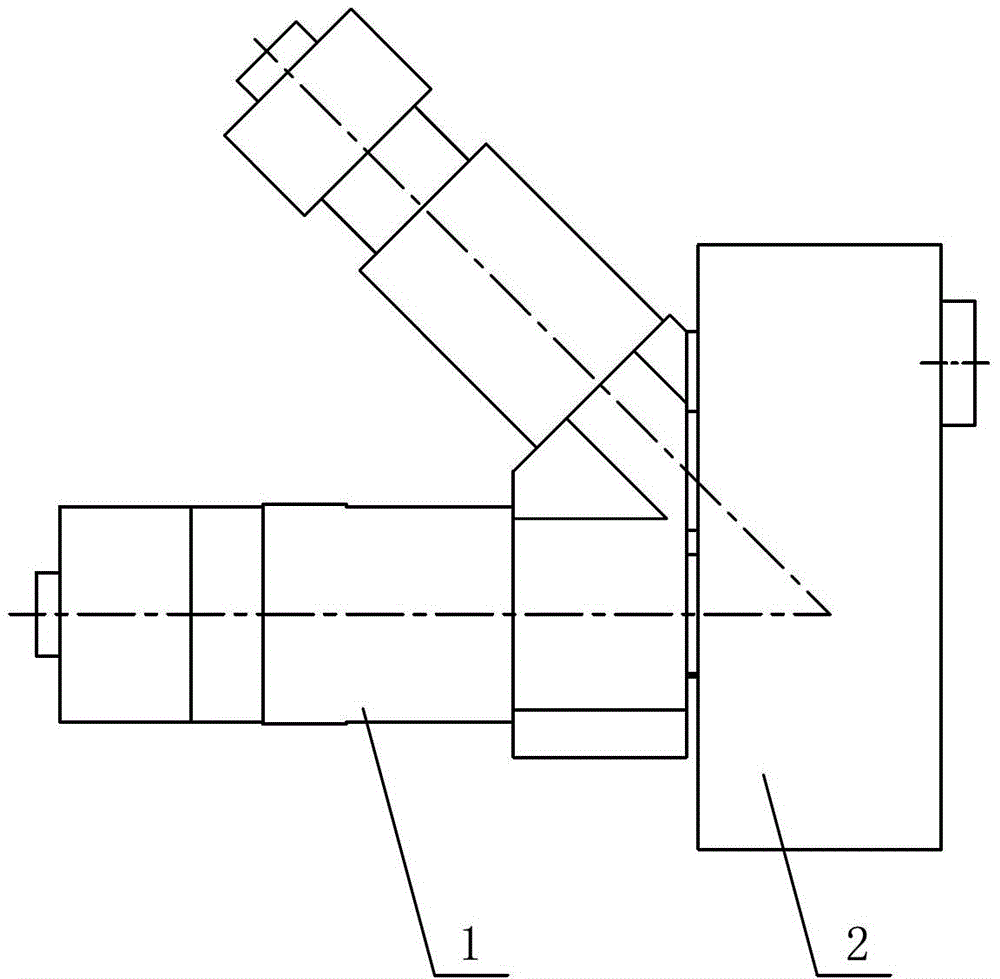

[0031] by figure 1 It can be seen that the sensing device of the fluorescent explosive detector of this embodiment is formed by connecting the air circuit assembly 1 and the optical assembly 2, and the optical assembly 2 is fixed to the air circuit assembly 1 by screws.

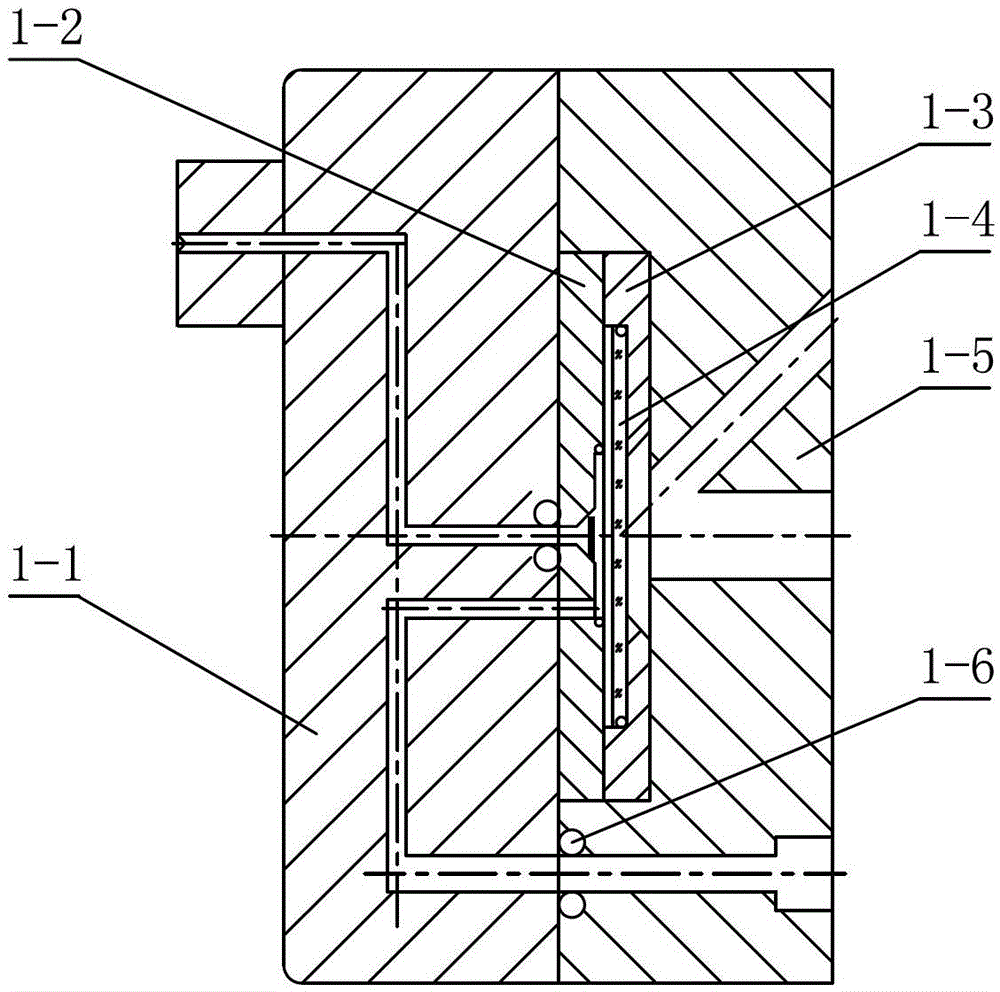

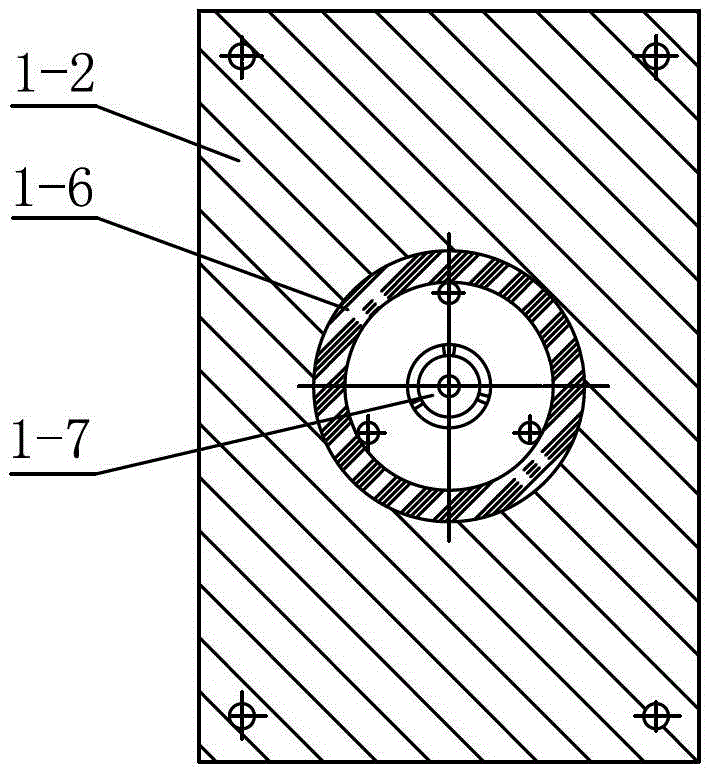

[0032] The above-mentioned air circuit assembly 1 is composed of the intake front cover 1-1, the sensor assembly front cover 1-2, the sensor assembly rear cover 1-3, the sensor film carrier 1-4, the light-transmitting rear cover 1-5, and the sealing ring 1-6 and baffle 1-7 connection structure, see figure 2 .

[0033] The air intake front cover 1-1 of this embodiment is made of aluminum alloy material. The air intake port is machined in the upper middle position of the air intake front cover 1-1, and the air intake front cover 1-1 is processed with the air intake port. The air inlet is connected to the air inlet channel, the upper air outlet channel and the lower air outlet channel are processed in sequence below...

Embodiment 2

[0045] In this embodiment, a first focusing lens 2-5 is installed in the first lens barrel 2-1 along the incident direction of the light source at a position 5 mm away from the emitting surface of the emitting light source 2-3, and the first focusing lens 2- 5 is a plano-convex lens with a radius of curvature of 15mm, the plane of the first focusing lens 2-5 is directly opposite to the light source, and the first narrow-band filter 2-6 is installed at a position where the center spacing of the convex side is 10mm.

[0046] A second filter 2-7 is installed in the second lens barrel 2-12 at a position 10 mm away from the sensor assembly along the emission direction of the fluorescence, and at a position 0.5 mm away from the center of the second filter 2-7 The condenser lens 2-8 is installed with a radius of curvature of 18mm, and the second focusing lens 2-9 is installed at a position 0.5mm away from the center of the condenser lens 2-8. The convex surface of the lens has a radius o...

Embodiment 3

[0051] In this embodiment, a first focusing lens 2-5 is installed in the first lens barrel 2-1 along the incident direction of the light source at a position 15 mm away from the emitting surface of the emitting light source 2-3. The first focusing lens 2- 5 is a plano-convex lens with a radius of curvature of 2mm. The plane of the first focusing lens 2-5 is directly opposite to the light source. The first narrow-band filter 2-6 is installed at the center of the convex side with a distance of 20mm. The bandwidth of filters 2-6 is 10nm.

[0052] A second filter 2-7 is installed at a position 10 mm away from the sensor assembly in the second lens barrel 2-12 along the emission direction of the fluorescence, and a second filter 2-7 is installed at a position 5 mm away from the center of the second filter 2-7 There is a condenser lens 2-8 with a radius of curvature of 2mm. A second focusing lens 2-9 is installed at a position 5mm away from the center of the condenser lens 2-8. The con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com