A micro-flattening device and method based on high-energy pulsed laser force effect

A leveling and laser technology, applied in auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., can solve the problems of difficult control of contact mechanical micro-leveling precision, difficult control of deformation, and difficulty in achieving micro-leveling, etc., to achieve large flexibility, Effect of short production cycle, improved corrosion resistance and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

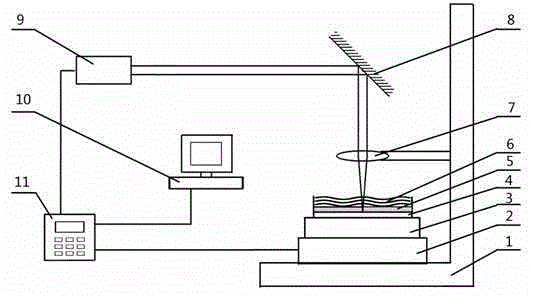

[0031] The present invention is a kind of micro-flattening device based on the force effect of high-energy pulsed laser such as figure 1 Shown:

[0032] A micro-leveling device based on the force effect of high-energy pulsed laser is composed of a laser drive control system, a target system and a target clamping displacement system. in:

[0033] The laser drive control system consists of a computer 10, a controller 11, a nanosecond laser 9, a plane reflector 8 and a focusing lens 7. The computer 10 controls the controller 11, and the controller 11 controls the laser beam emitted by the nanosecond laser 9 to pass through the plane reflector. 8, reflected to the focusing lens 7 and then directly enters the target system; the target system is composed of a water layer 6, a black paint layer 5 and a target 4, and the water layer is used as a constraint layer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com