Method for synthesizing ammonia borane

A synthesis method, ammonia borane technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as high cost and complicated process, achieve solvent saving, cost reduction, simple and cheap preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Put 26.21g of ammonium fluoroborate and 9.46g of sodium borohydride (the molar ratio of ammonium fluoroborate and sodium borohydride is 1) into a reactor with a reflux device containing 250 milliliters of dioxane solvent, The prepared ammonium fluoroborate-sodium borohydride-dioxane mixed solution was then heated and stirred for at least 10 hours, and the heating temperature was 40°C;

[0026] (2) Suction filter the mixed solution obtained through the reaction in step (1) to obtain a clear and transparent solution;

[0027] (3) Rotate the clear and transparent solution obtained in step (2) at 70°C to obtain a white light sample, which is ammonia borane;

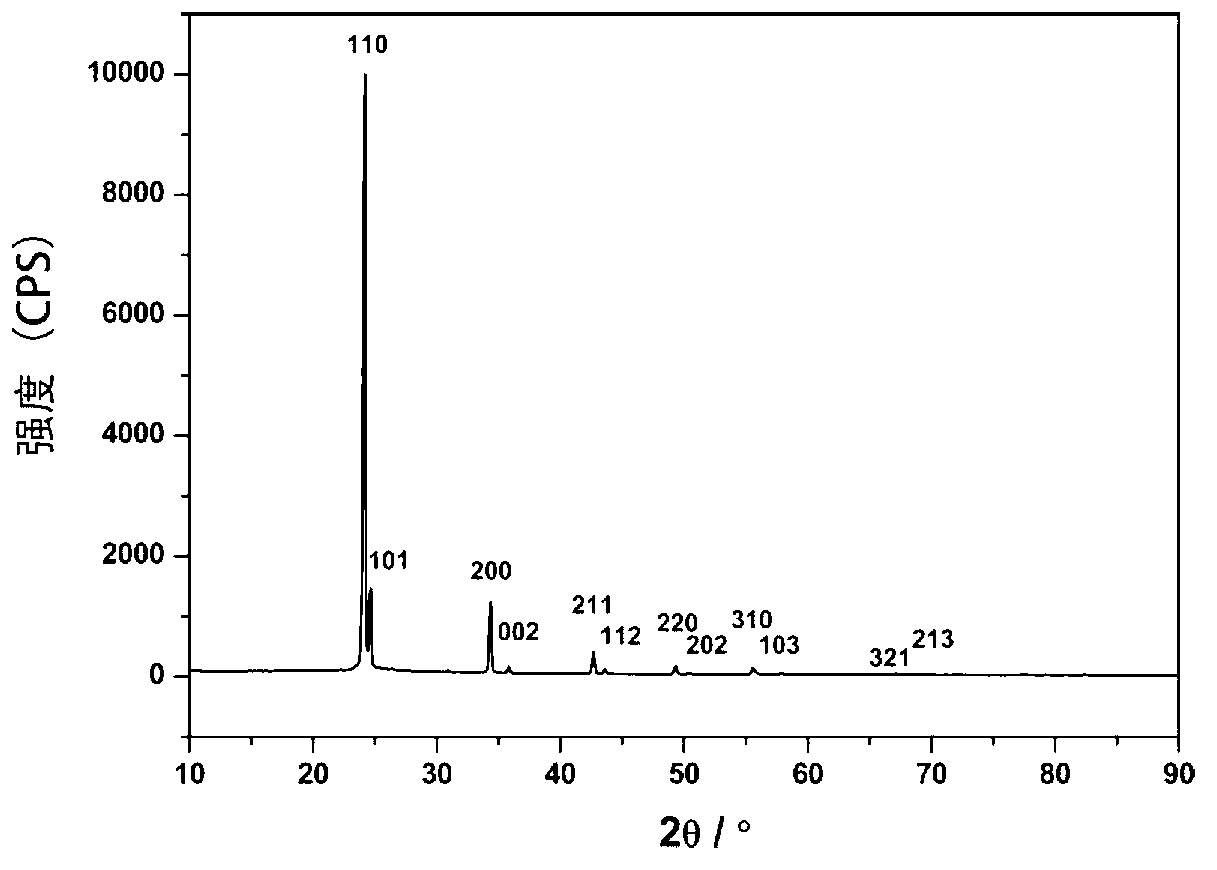

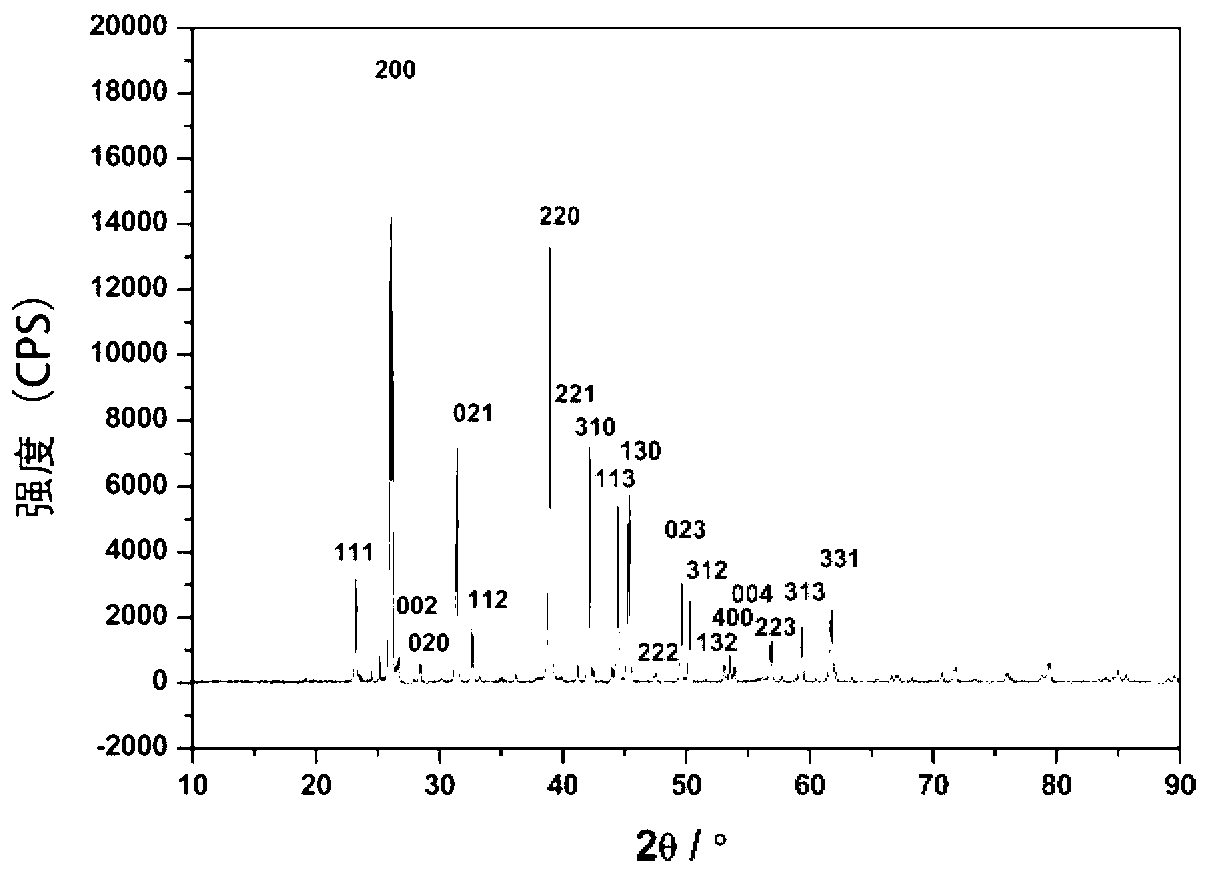

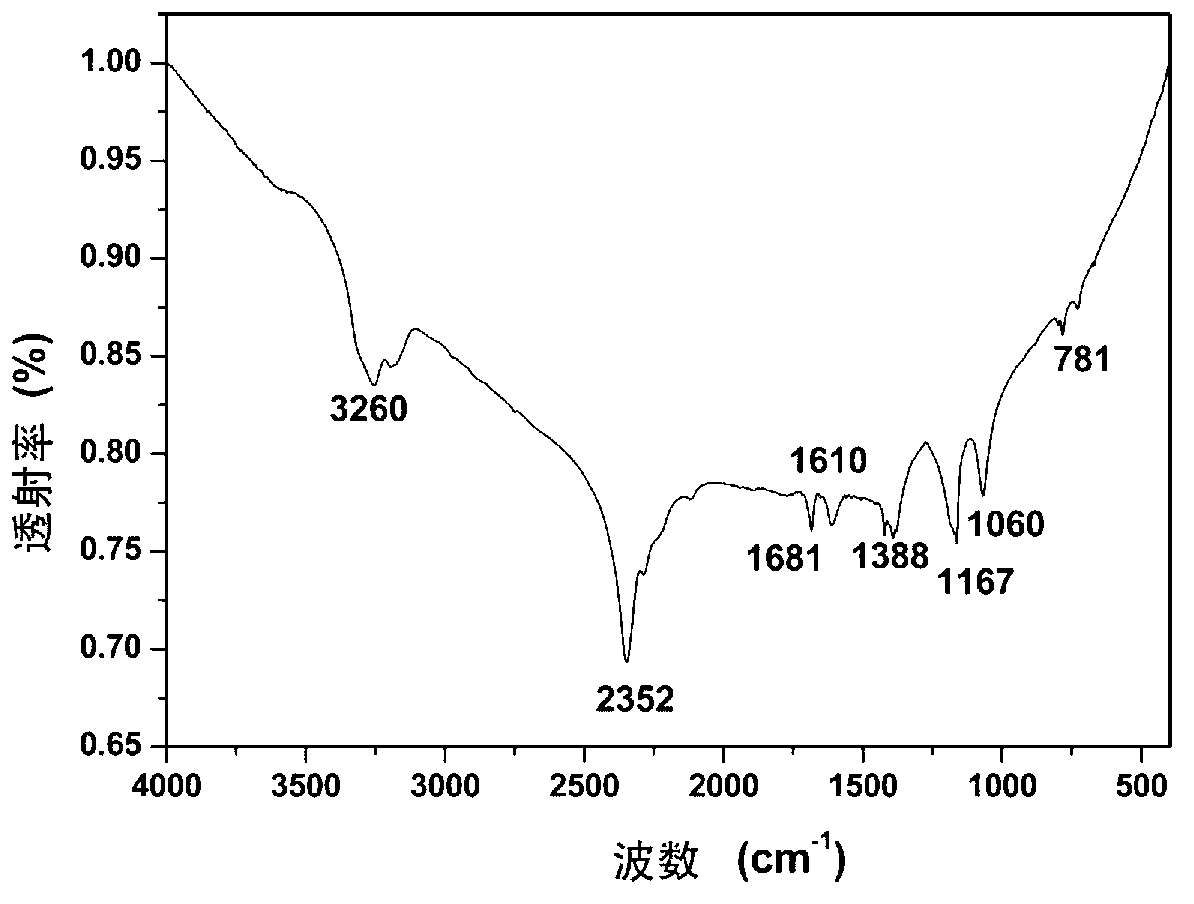

[0028] Such as figure 1 Shown is the X-ray diffraction (XRD) pattern of the product. Within the measured diffraction angle range, each diffraction peak is very clear and sharp. One-to-one correspondence of diffraction data indicates that it has high purity and crystallinity. There are no diffraction peaks of oth...

Embodiment 2、 example 3

[0030] Change step (1) ammonium fluoroborate in Example 1 to 13.11g and 52.42g (the molar ratios of ammonium fluoroborate and sodium borohydride are 0.5 and 2 respectively), and other operations are the same as in Example 1 to obtain Product is with embodiment 1.

Embodiment 4、 example 5

[0032] Change the amount of sodium borohydride in step (1) in Example 1 to 4.73g and 18.92g respectively (the molar ratios of ammonium fluoroborate and sodium borohydride are 2 and 0.5 respectively), and all other operations are the same as in Example 1 Identical, obtain product with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com