Working solution for producing hydrogen peroxide through stationary bed palladium catalyst process, and preparation method of working solution

A technology of hydrogen peroxide and palladium catalyst, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve low production capacity, cycle reduce the amount of hydrogen, and achieve the effect of improving hydrogen efficiency, reducing side reactions, and high distribution coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

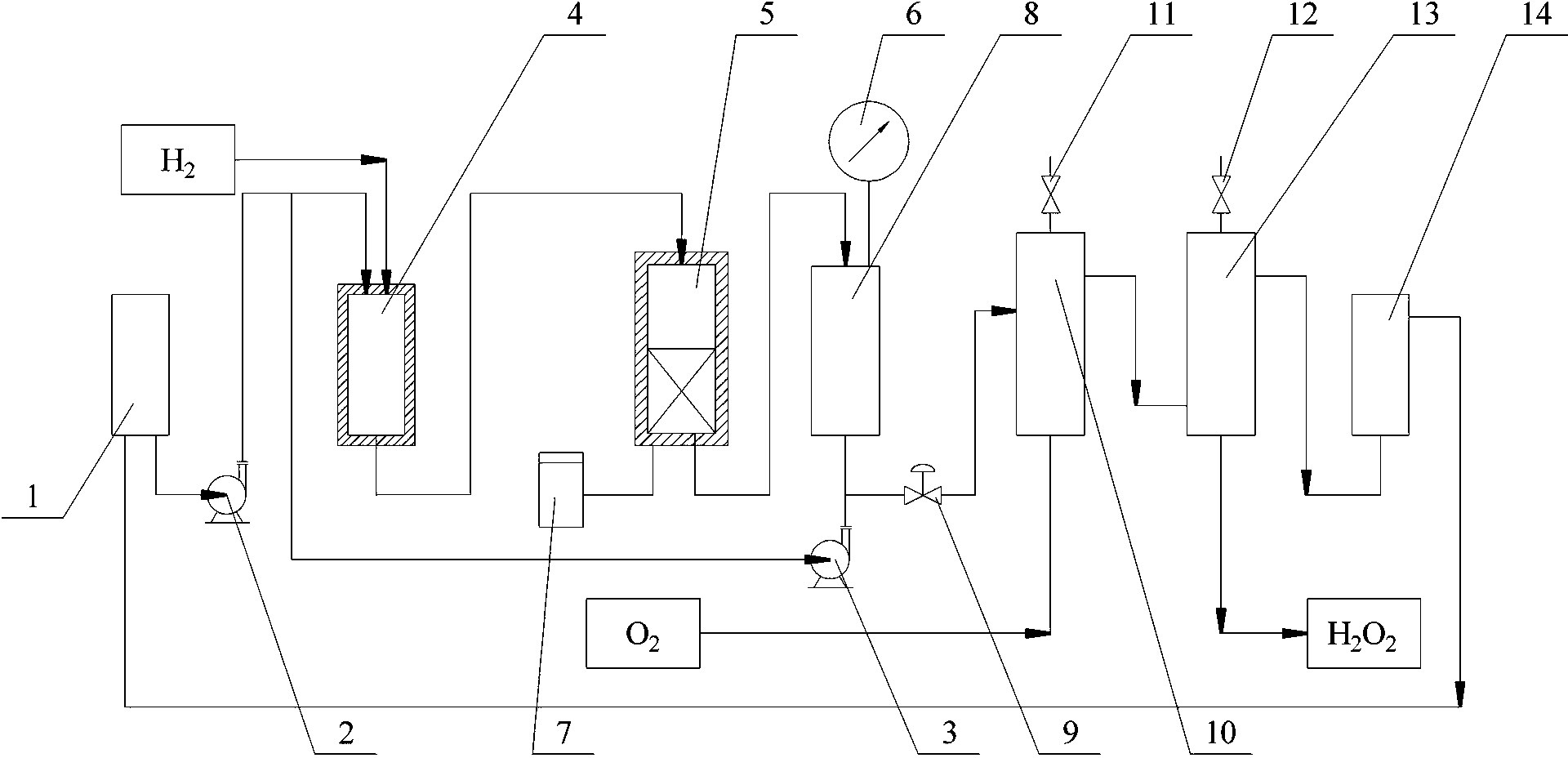

[0094] Get 65 liters of heavy aromatics, 35 liters of 2-MCHA, and dissolve 30kg of 2-amylanthraquinone in the above-mentioned solvent, use figure 1 The test device, the diameter of the hydrogenation tower is 40mm, the height is 1425mm, and the catalyst loading is 400ml. Pass the above working fluid through the catalyst bed with a flow rate of 10 liters, equivalent to a space velocity of 25 hr -1 , the reaction temperature is 45°C, the hydrogen effect is 17.75g, the specific gravity of the working fluid is 0.963 (25°C), the oxidation time is 3 minutes, and the working fluid is 35%H 2 o 2 The lower partition coefficient is 76, at 45%H 2 o 2 The next is 78.

Embodiment 2

[0096] Get 65 liters of heavy aromatics, 20 liters of 2-MCHA, and 15 liters of DIBC, and dissolve 25 kg of 2-amylanthraquinone in the above-mentioned solvent, and use the same method as in Example 1 to obtain 16.8 g of hydrogen, and the oxidation time is 2 minutes and 30 seconds. The specific gravity of the working fluid is 0.934 (25°C), 35%H 2 o 2 The time distribution coefficient is 71,45%H 2 o 2 for 73.

Embodiment 3

[0098] Get 60 liters of heavy aromatics, 40 liters of 2-MCHA, dissolve 10kg 2-ethylanthraquinone and 15kg 2-amylanthraquinone in the above-mentioned solvent, use the same method as in Example 1 to obtain a hydrogen effect of 13g, and the oxidation time is 2 minutes, working fluid specific gravity 0.96, 35%H 2 o 2 When the distribution coefficient is 50,45% is 93.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com