Method for synthesizing pure-phase SAPO-41 molecular sieve by use of crystallization mother liquid

A technology of SAPO-41 and crystallization mother liquor, which is applied in the direction of molecular sieve silicoaluminophosphate, molecular sieve and alkali exchange phosphate, etc., can solve the problems of raw material waste environment, high synthesis cost, and miscellaneous crystals in the product, so as to save raw materials , increase the nucleation speed and quantity, and avoid the effect of heterocrystalline phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

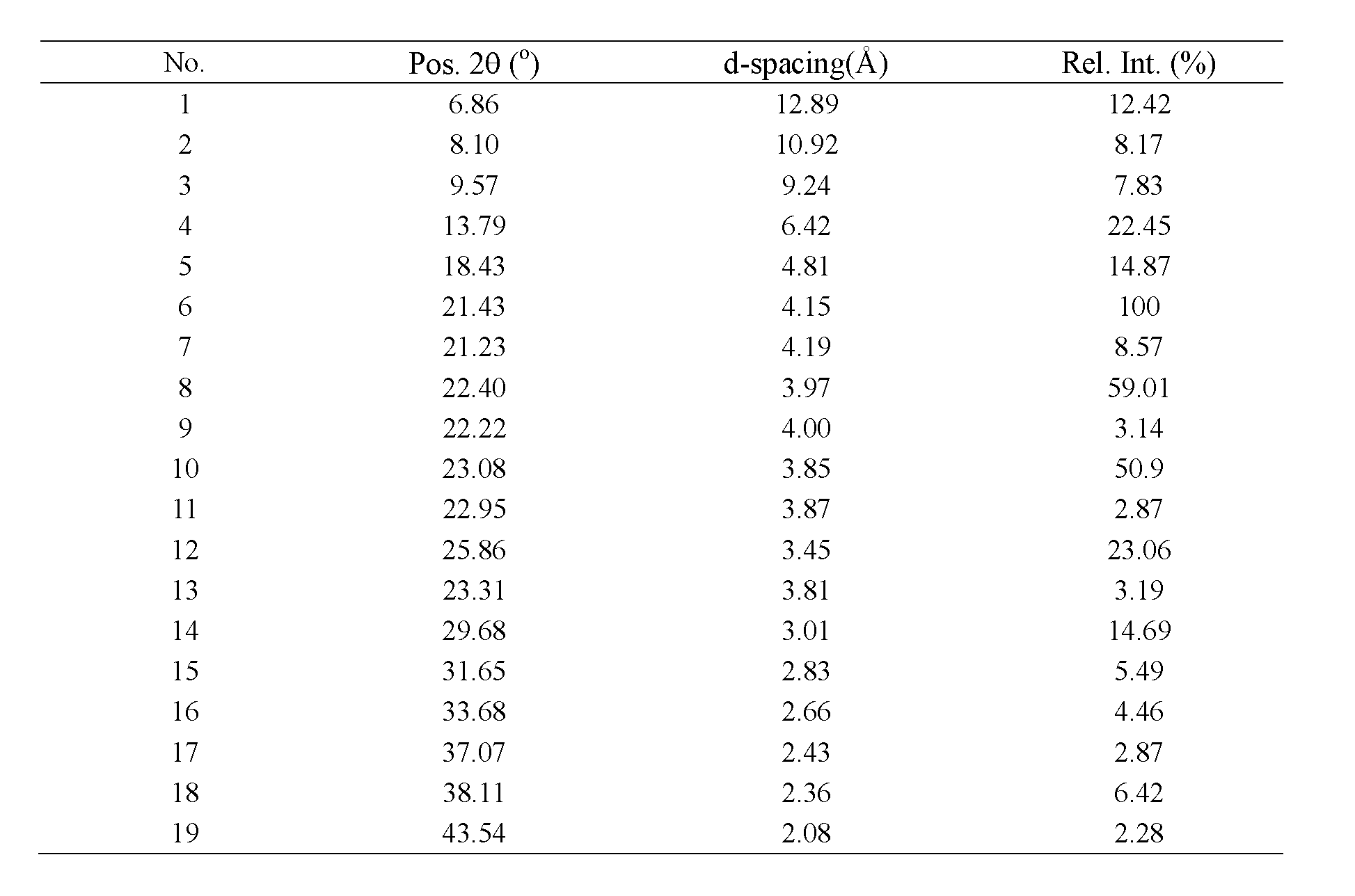

[0020] Add 156g of pseudoboehmite into 600g of deionized water, and stir for 30min. Then under vigorous stirring, a solution formed by 272.1g of phosphoric acid (85wt%) and 401.1g of deionized water was slowly added dropwise, then 357.2g of di-n-propylamine (chemically pure, 97wt%) was added dropwise, and then silica sol (30wt% SiO 2 ) 24g to form a sol mixture, which was transferred into a stainless steel crystallization kettle and crystallized at 185°C under autogenous pressure for 38h. Cool after crystallization, filter the cooled solid-liquid mixture through a 0.1 μm membrane, recycle the mother liquor containing microcrystals, continue washing the solid product with water until neutral, and dry the solid product at 100°C for 17 hours to obtain Molecular sieve raw powder. The raw molecular sieve powder was calcined at 550°C for 10 hours in an air atmosphere to remove the template agent to obtain SAPO-41 molecular sieve. The X-ray diffractometer test results are shown in ...

Embodiment 2

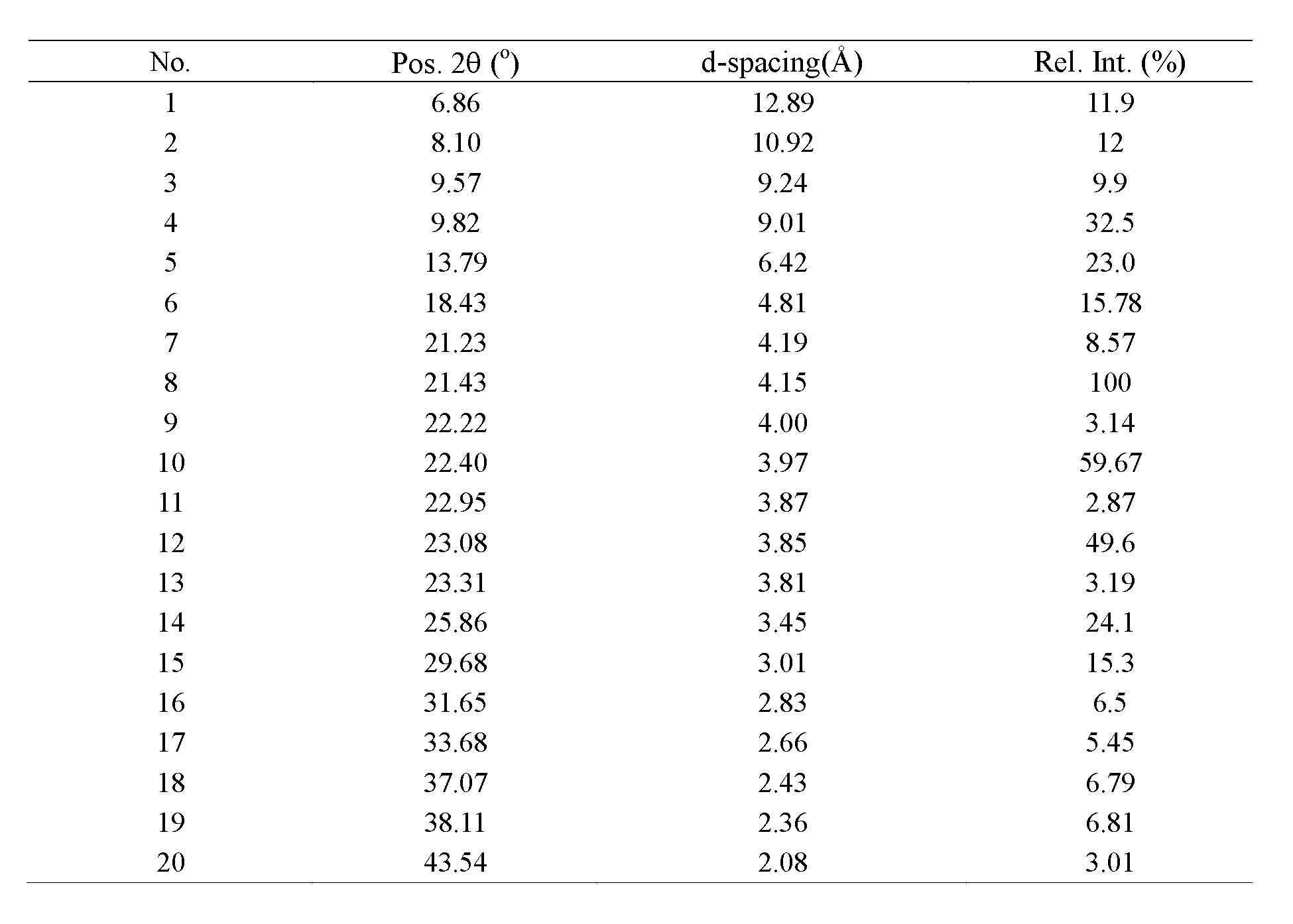

[0025] The crystallization mother liquor recovered in Example 1 is used as a synthetic raw material, and after analyzing the component content, it is mixed with a certain amount of pseudo-boehmite, phosphoric acid, di-n-propylamine, silica sol, and deionized water to form a sol mixture, and the SAPO-41 Molecular sieve synthesis, the specific feeding is as follows:

[0026] Add 78g of pseudo-boehmite into 200g of deionized water, and stir for 30min. Then under vigorous stirring, a solution formed by 136g of phosphoric acid (85%) and 321g of deionized water was slowly added dropwise, and then 178.6g of di-n-propylamine (chemically pure, 97%) and 529.4g of crystallization containing 178.4g of di-n-propylamine were added dropwise. Mother liquor, then add silica sol (30wt% SiO 2 ) 24g to form a sol mixture, which was transferred into a stainless steel crystallization kettle and crystallized at 185°C for 36h under autogenous pressure. Cool after crystallization, filter the cooled ...

Embodiment 3

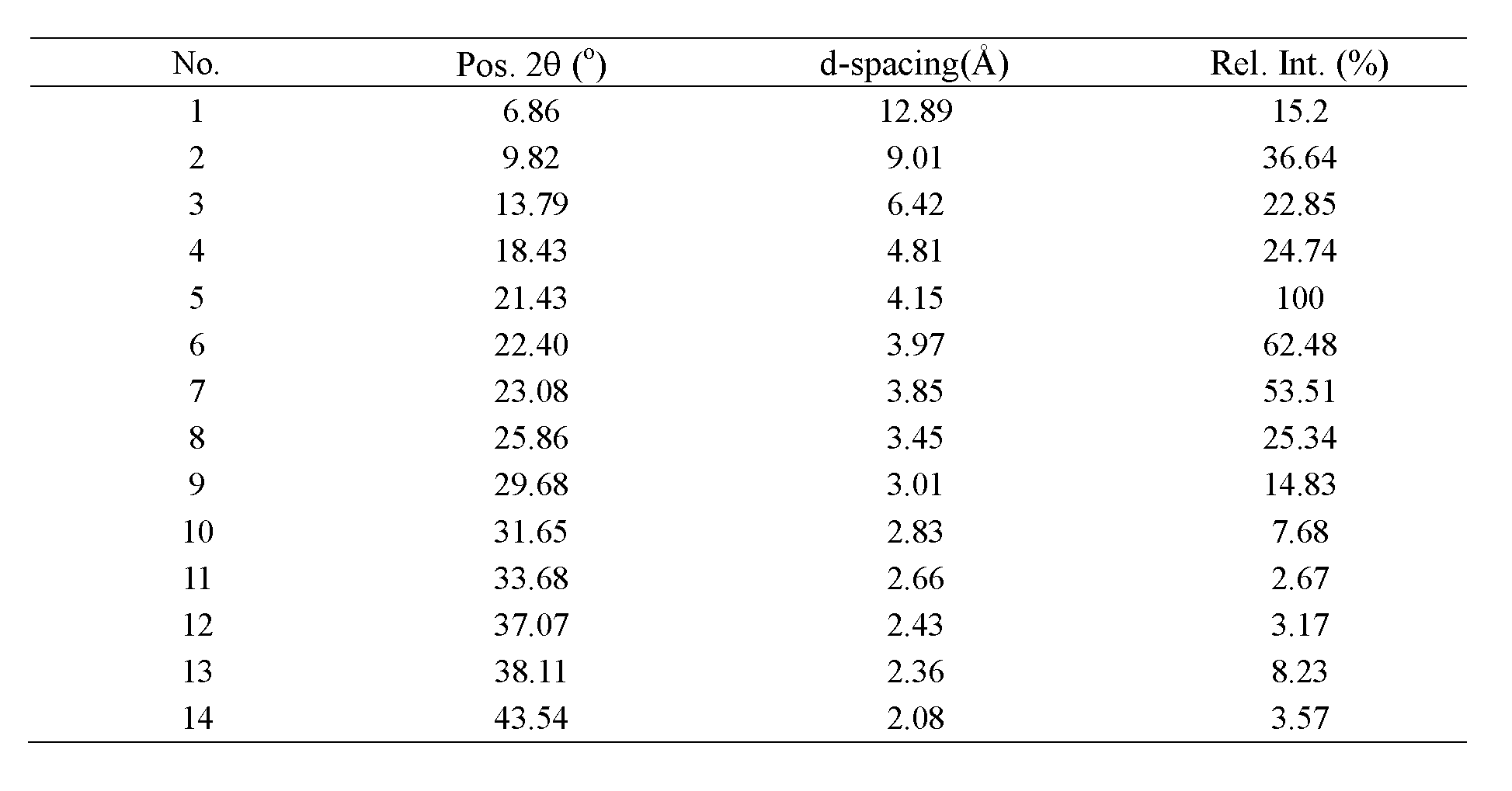

[0030] The crystallization mother liquor recovered in Example 2 is used as a synthetic raw material, and after analyzing the component content, it is mixed with a certain amount of pseudoboehmite, phosphoric acid, di-n-propylamine, silica sol, and deionized water to form a sol mixture, and the sol is assisted by microwave After heat treatment, carry out SAPO-41 molecular sieve synthesis, specific feeding and operation are as follows:

[0031] Add 49.9g of pseudo-boehmite into 300g of deionized water, and stir for 30min. Then under vigorous stirring, a solution formed by 87g of phosphoric acid (85%) and 48.1g of deionized water was slowly added dropwise, and then 114.3g of di-n-propylamine (chemically pure, 97%) and 720g of a crystallization solution containing 242.6g of di-n-propylamine were added dropwise. Mother liquor, then add silica sol (30wt% SiO 2) 24g to form a sol mixture, and the sol was heated under microwave-assisted heating (heating temperature 55° C.), and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com