Method for preparing fluorine-containing benzoxazole liquid crystal compound

A technology of liquid crystal compounds and benzoxazoles, which is applied in the field of materials, can solve the problems of many reaction steps, high cost, and low yield, and achieve the effect of simple operation, low cost, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

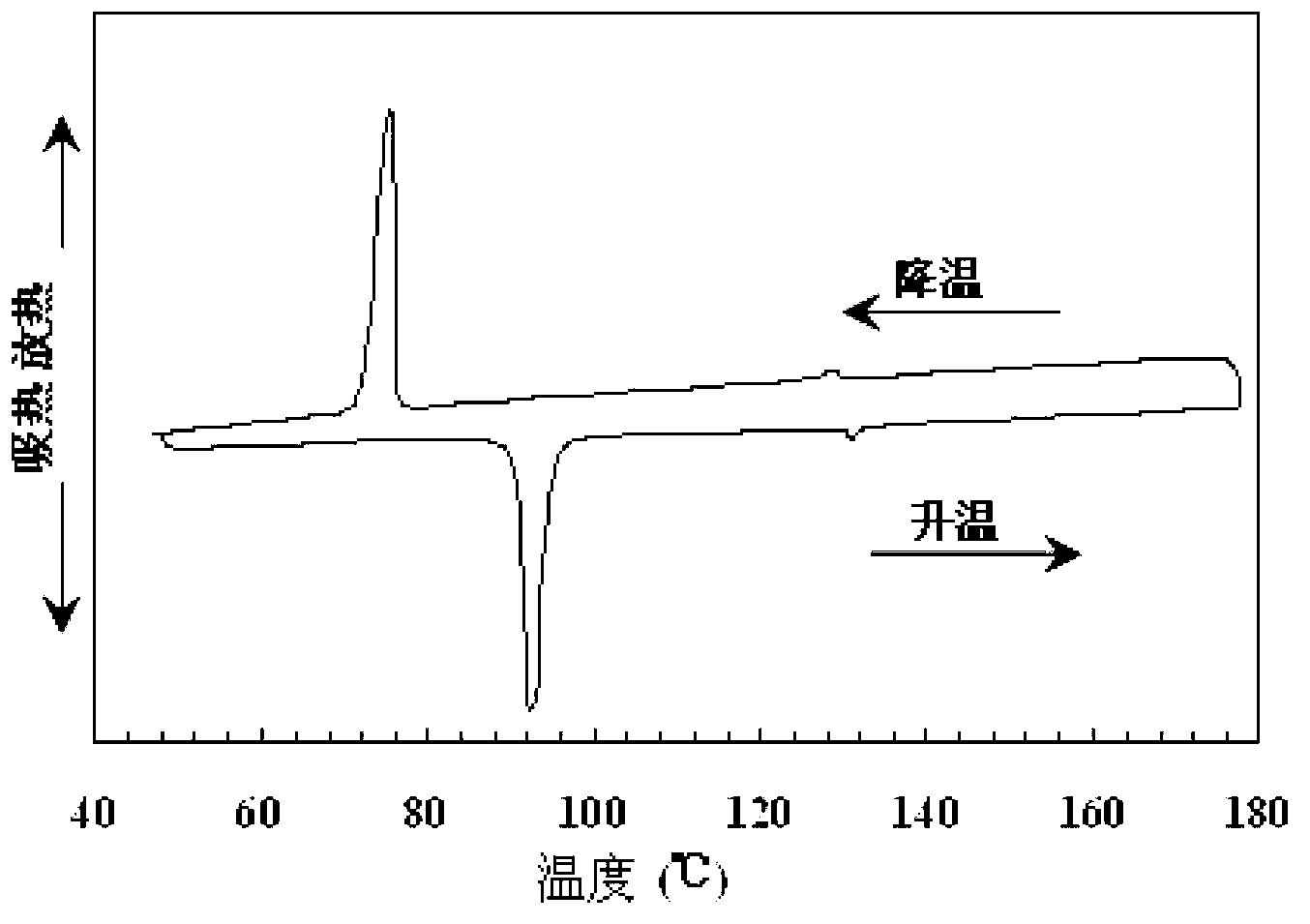

Image

Examples

Embodiment 1

[0026] Taking the preparation of 2-(4'-octyloxy-2',3'-difluorobiphenyl)benzoxazole as an example, the preparation method is as follows:

[0027] 1. Preparation of 4′-octyloxy-2′,3′-difluorobiphenylformaldehyde

[0028] Under nitrogen protection at a flow rate of 0.6mL / min, 20.8g (0.10mol) of 4-hydroxy-2,3-difluorobromobenzene, 41.4g (0.3mol) of potassium carbonate, 19.0mL (0.11mol) of 1-bromo Add octane into a three-necked flask containing 240mL N,N-dimethylformamide, raise the temperature to 70°C under stirring at 350 rpm and react for 6 hours, and then add 16.5g (0.11mol) 4-methanol to the three-necked flask Acylphenylboronic acid, 1.2g (1mmol) tetrakis (triphenylphosphine) palladium and 40mL distilled water, 4-hydroxy-2,3-difluorobromobenzene and 1-bromooctane, potassium carbonate, 4-formylphenylboronic acid , The molar ratio of tetrakis(triphenylphosphine)palladium, N,N-dimethylformamide, and distilled water is 1:1.1:3:1.1:0.01:30:22, the temperature is raised to 100°C, a...

Embodiment 2

[0037] In step 2 of the preparation of 2-(4′-octyloxy-2′,3′-difluorobiphenyl)benzoxazole in Example 1, 3.04 g (0.01 mol) of 4′-octyloxy- Add 2′,3′-difluorobiphenyl formaldehyde and 1.2g (0.011mol) of o-aminophenol into a three-necked flask filled with 30mL of 1,2-dichloroethane, stir at 350 rpm, and reflux at 80°C for 5 hours, then 2.3g (0.01mol) 2,3-dichloro-5,6-dicyanobenzoquinone was added to the three-necked flask, and 4′-octyloxy-2′,3′-difluorobiphenylformaldehyde The molar ratio of o-aminophenol, 2,3-dichloro-5,6-dicyanobenzoquinone, and 1,2-dichloroethane is 1:1.1:1.0:38, react at 10°C for 8 hours, other steps Same as in Example 1, 2-(4′-octyloxy-2′,3′-difluorobiphenyl)benzoxazole was obtained with a total yield of 58%.

Embodiment 3

[0039] In step 2 of the preparation of 2-(4′-octyloxy-2′,3′-difluorobiphenyl)benzoxazole in Example 1, 3.04 g (0.01 mol) of 4′-octyloxy- Add 2′,3′-difluorobiphenyl formaldehyde and 1.2g (0.011mol) of o-aminophenol into a three-necked flask filled with 60mL of 1,2-dichloroethane, stir at 350 rpm, and reflux at 80°C for 5 hours, then add 3.4g (0.015mol) 2,3-dichloro-5,6-dicyanobenzoquinone into the three-necked flask, 4′-octyloxy-2′,3′-difluorobiphenylformaldehyde The molar ratio of o-aminophenol, 2,3-dichloro-5,6-dicyanobenzoquinone, and 1,2-dichloroethane is 1:1.1:1.5:76, react at 50°C for 3 hours, other steps Same as in Example 1, 2-(4′-octyloxy-2′,3′-difluorobiphenyl)benzoxazole was obtained with a total yield of 61%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com