Method for preparing liquid butadiene rubber anti-aging agent

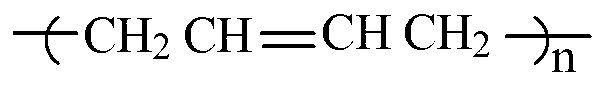

A rubber antioxidant and liquid cis-butadiene technology, applied in the field of composite antioxidants, can solve the problems of inconvenient use of antioxidants, uncontrollable cross-linking aging of cis-butadiene rubber, increase in gel content and Mooney viscosity, etc. Comprehensive anti-aging performance, good synergistic effect, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

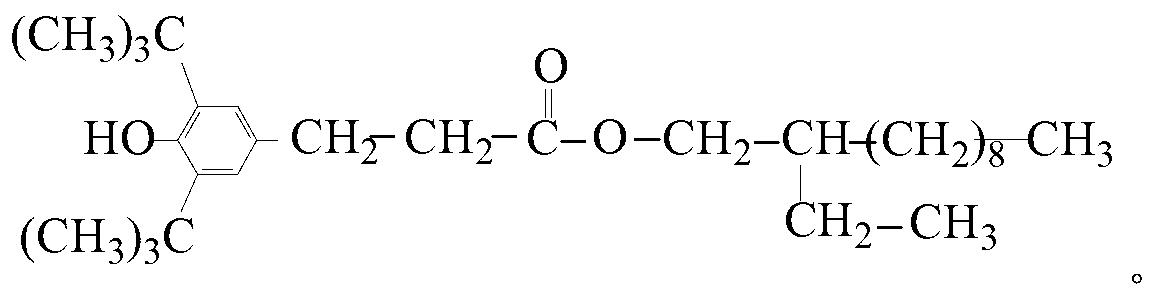

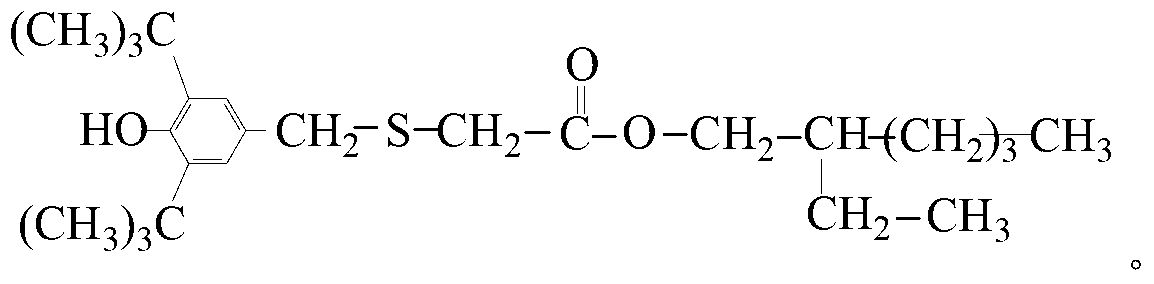

[0041] Weigh 200 grams of 2,6-di-tert-butyl-4-methylene-S-acetate isooctylphenol, β-(4-hydroxy-3,5-di-tert-butylphenyl) propionate 125 grams of triol esters, 50 grams of bis(isotridecyl) pentaerythritol diphosphite, 20 grams of N,N-dibutyl hydroxylamine, 2 grams of 2,2,6,6-tetramethylpiperidinol, Add them respectively to the blending kettle, raise the temperature to 60-65°C, stir for 0.5h to mix evenly to form a liquid mixture, cool to room temperature 30-35°C, and obtain the 1# liquid anti-aging agent of the present invention.

Embodiment 2

[0043] Weigh 200 grams of 2,6-di-tert-butyl-4-methylene-S-acetate isooctylphenol, β-(4-hydroxy-3,5-di-tert-butylphenyl) propionate 110 grams of triol esters, 70 grams of bis(isotridecyl) pentaerythritol diphosphite, 10 grams of diethylhydroxylamine, 10 grams of 2,2,6,6-tetramethylpiperidinol, respectively added to the blending kettle , heat up to 60-65°C, stir for 0.5h and mix evenly to form a liquid mixture, cool to room temperature 30-35°C, and obtain 2# liquid anti-aging agent of the present invention.

Embodiment 3

[0045] Weigh 200 grams of 2,6-di-tert-butyl-4-methylene-S-acetate isooctylphenol, β-(4-hydroxy-3,5-di-tert-butylphenyl) propionate 80 grams of triol ester, 80 grams of bis(isotridecyl) pentaerythritol diphosphite, 25 grams of isopropyl hydroxylamine, and 15 grams of 2,2,6,6-tetramethylpiperidinol were added to the blending kettle , heat up to 60-65°C, stir for 0.5h and mix evenly to form a liquid mixture, cool to room temperature 30-35°C, and obtain 3# liquid anti-aging agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com