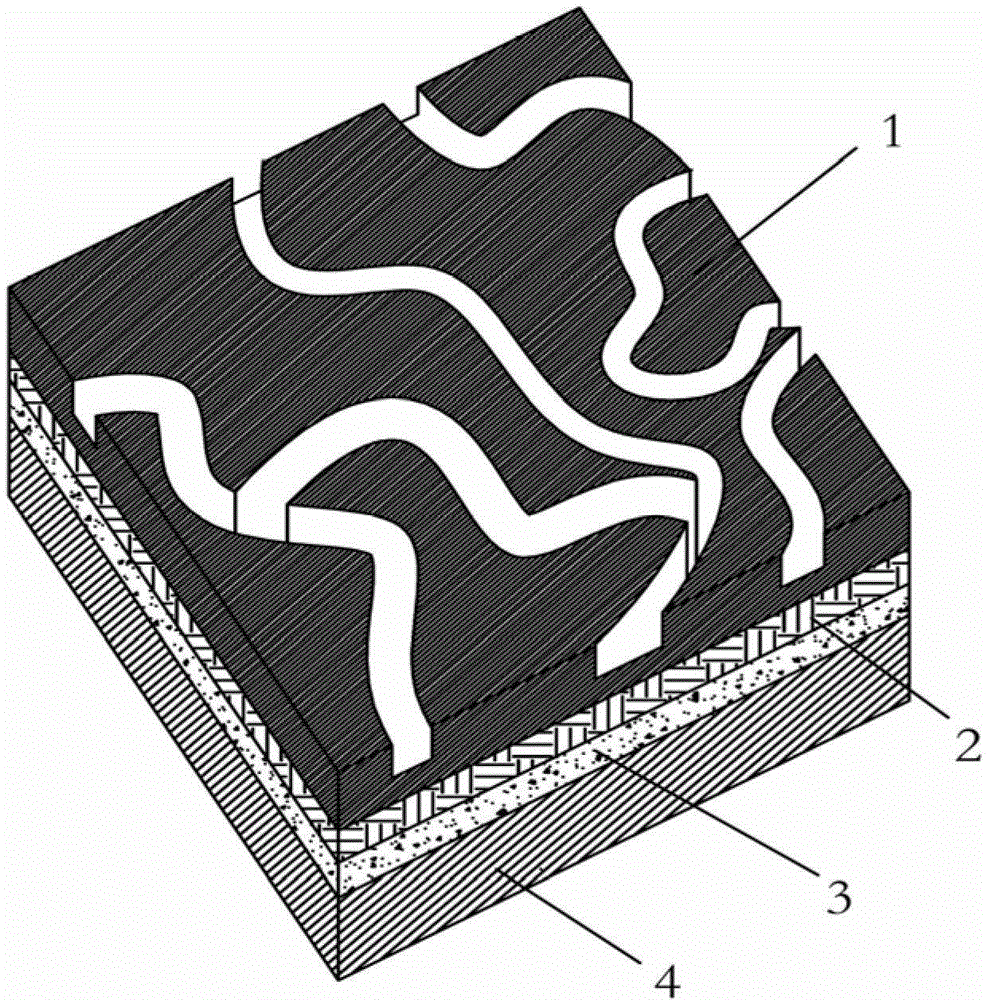

Embossed plate and its forming process

A molding process and embossing technology, which is applied in the direction of synthetic resin layered products, paper/cardboard layered products, lamination, etc., can solve the problems that the effect cannot give people a real and natural aesthetic feeling, the processing technology is complicated, and the production efficiency is low. , to achieve the effect of enhanced three-dimensional appearance, simple process and convenient molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

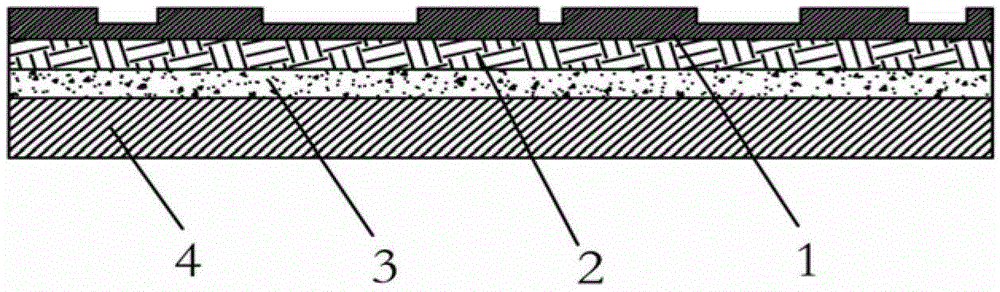

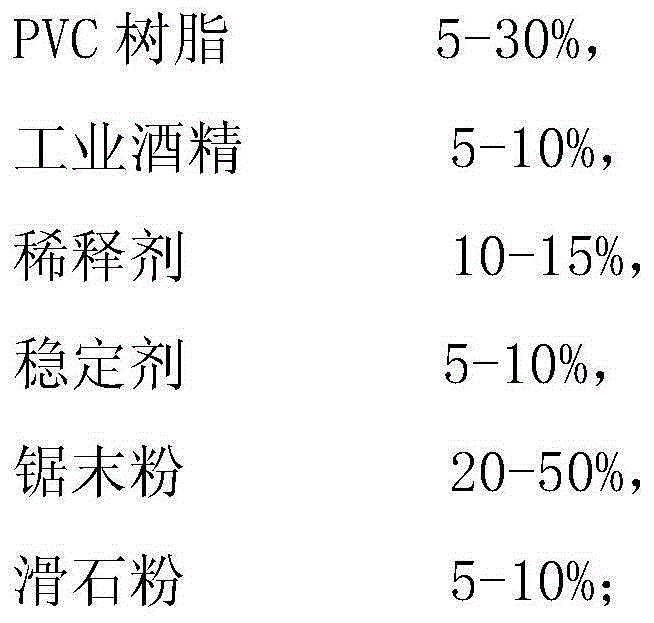

[0049] The mixture to form the relief layer 1 uses the following ratio:

[0050]

[0051] Add 12% diluent to 15% of the total weight of PVC resin and stir evenly, then add 8% stabilizer, stir evenly and stand for 2 hours as a spare raw material; add 50% sawdust powder and 8% talc to the above spare raw material Mix the powder into the mold after stirring, apply vibration to the mold to form a mixture; spread a layer of the above-mentioned mixture on the surface of the glass fiber cloth 2; use the mold to roll the surface of the mixture to form a relief layer 1; The layer 1 is dried for 1 hour, and the dried relief layer 1 is subjected to the surface treatment of base color change and spray paint.

Embodiment 2

[0053] The mixture to form the relief layer 1 uses the following ratio:

[0054]

[0055] Add 15% diluent to the PVC resin which accounts for 20% of the total weight and stir evenly, then add 7% stabilizer, stir evenly and stand for 2.5 hours as a spare raw material; add 40% sawdust powder and 10% talc Mix the powder into the mold after stirring, apply vibration to the mold to form a mixture; spread a layer of the above-mentioned mixture on the surface of the glass fiber cloth 2; use the mold to roll the surface of the mixture to form a relief layer 1; The layer 1 is dried for 1.5 hours, and the dried relief layer 1 is subjected to the surface treatment of base color change and spray paint.

Embodiment 3

[0057] The mixture uses the following ratio:

[0058]

[0059] Add 10% diluent to 25% of the total weight of PVC resin and stir it evenly, then add 8% stabilizer and stir it evenly and let it stand for 3 hours as a spare raw material; add 35% sawdust powder and 8% talc to the above spare raw material Mix the powder into the mold after being evenly stirred, and apply vibration to the mold to form a mixture; spread a layer of the above-mentioned mixture on the surface of the glass fiber cloth 2; use the mold to roll the surface of the mixture to form a relief layer 1; The layer 1 is dried for 1.5 hours, and the dried relief layer 1 is subjected to the surface treatment of base color change and spray paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com