Hard-carbon negative electrode material for lithium ion secondary battery and preparation method thereof

A technology for secondary batteries and negative electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of high cost, difficult industrialized production, and complicated preparation methods, and achieves low cost, stable product properties, and simple and easy process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

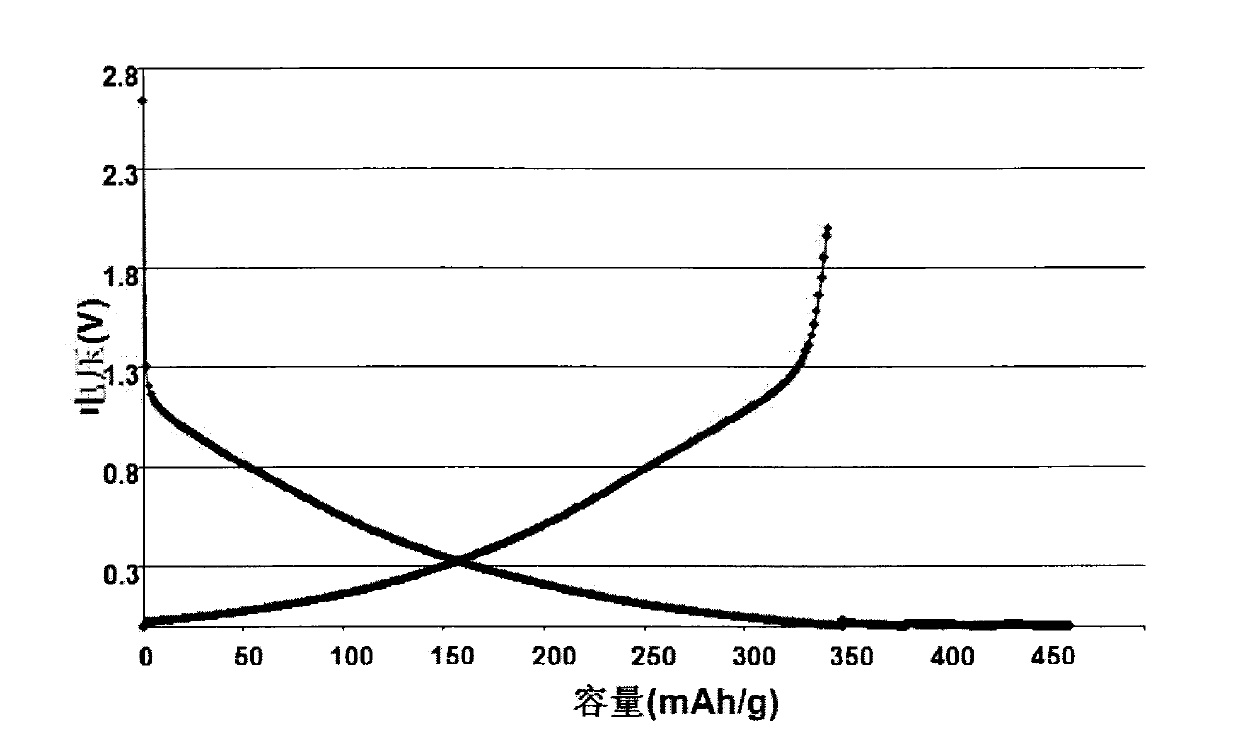

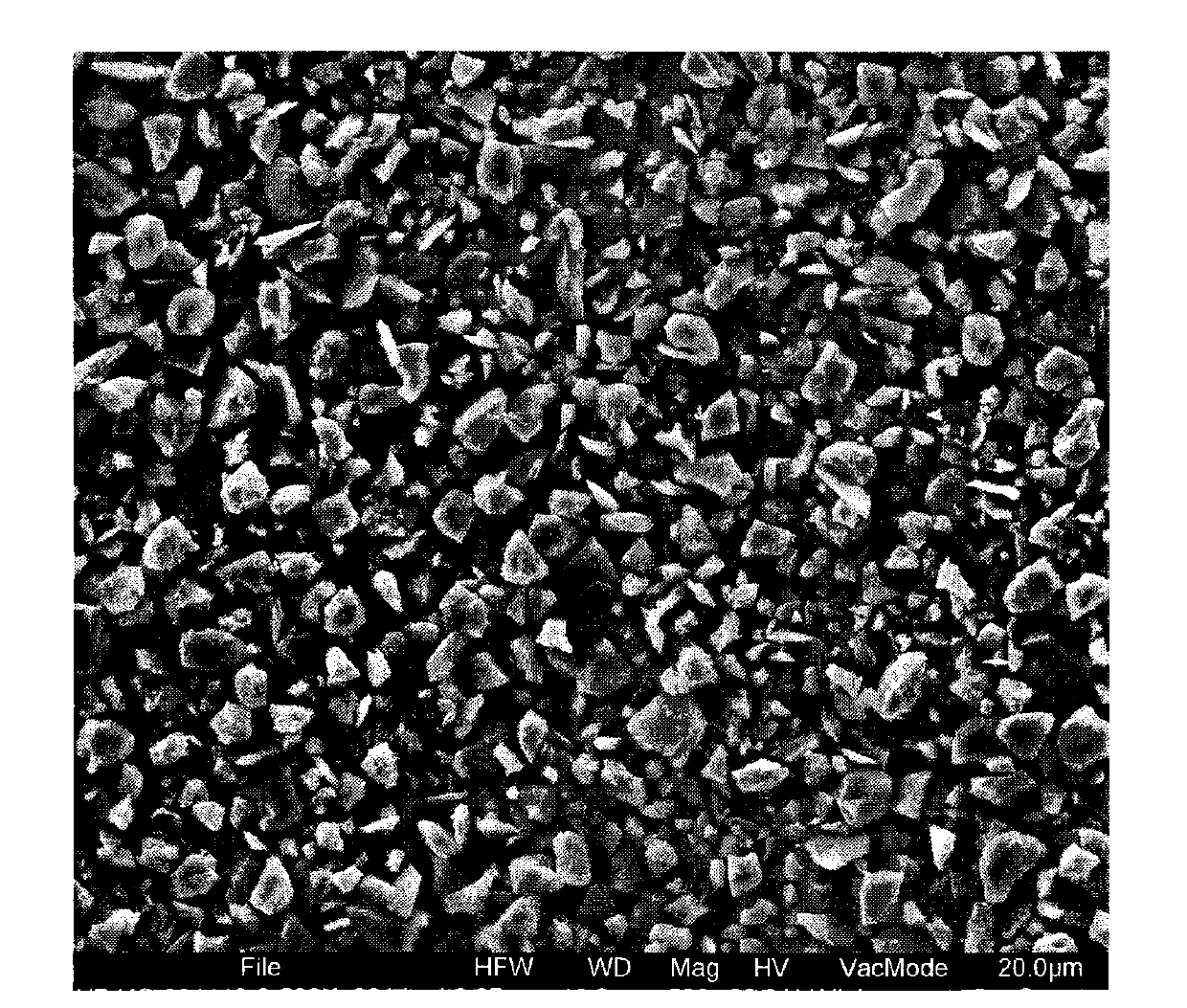

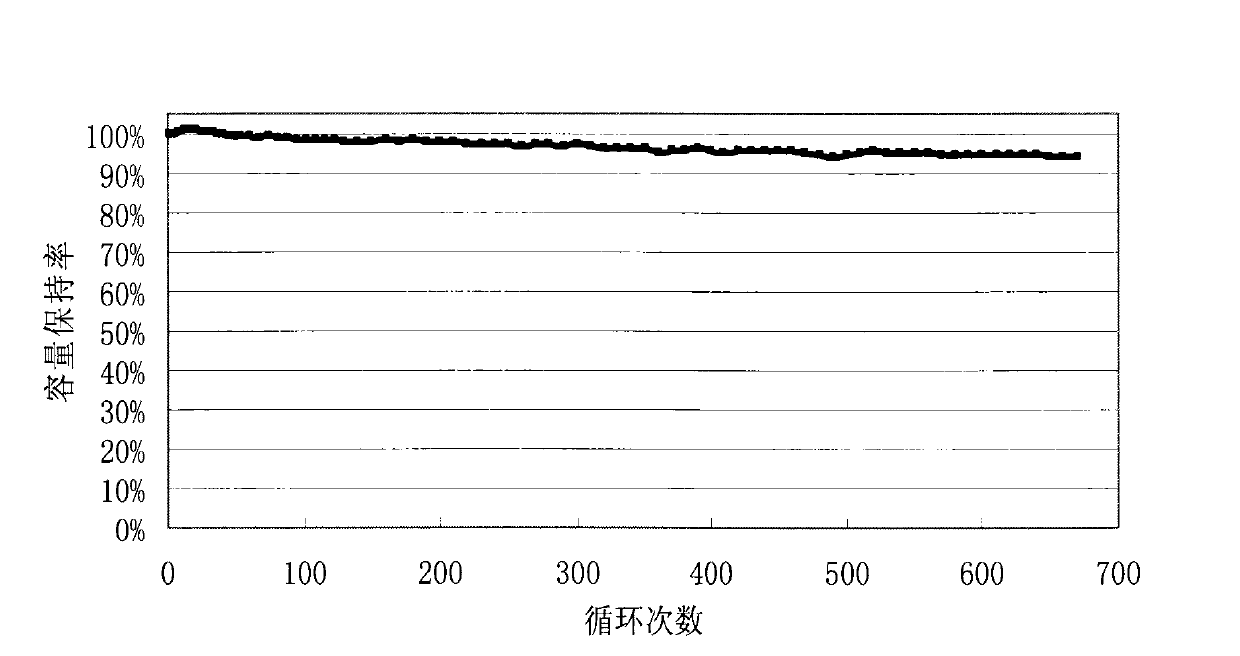

Embodiment 1

[0034] ①Put refined anthracene and benzaldehyde into the reaction kettle with a mass ratio of 2:1 under stirring, and carry out cross-linking polymerization reaction at 180°C for 2 hours; After 4 hours, cool down to room temperature and discharge, then pulverize with a pulverizer at a speed of 1000 rpm, pass through a 60-mesh sieve, take the under-sieve and put it into a well-type carbonization furnace, and carry out pre-carbonization treatment at 700 °C under an inert atmosphere for 16 3 hours, down to room temperature; ③ pulverize with a pulverizer at a speed of 2000 rpm, pass through a 60-mesh sieve, take the sieve and heat-treat at 1000 °C for 18 hours in a high-temperature carbonization furnace of a pusher kiln under an inert atmosphere; ④ pulverize by airflow Classifier pulverization and classification are carried out with compressed air pressure of 8 MPa, feed frequency of 21 Hz and classifier frequency of 105 Hz to obtain a hard carbon negative electrode material with a...

Embodiment 2

[0036]①Add refined anthracene and formaldehyde into the reaction kettle with stirring at a ratio of 5:2 by mass, and carry out cross-linking polymerization reaction at 100°C for 4 hours; hours, lowered to room temperature and discharged, and then pulverized by a pulverizer at a speed of 800 rpm, passed through a 60-mesh sieve, and the undersieve was taken into a well-type carbonization furnace, and pre-carbonized at 600°C for 24 hours under an inert atmosphere. , down to room temperature; ③ crush with a pulverizer at a speed of 5000 rpm, pass through a 60-mesh sieve, and take the sieve and heat-treat at 1500 °C for 12 hours in a high-temperature carbonization furnace of a pusher kiln under an inert atmosphere; ④ pass through a jet crushing classifier Pulverization and classification are carried out with compressed air pressure of 9 MPa, feed frequency of 25 Hz and classifier frequency of 90 Hz to obtain a hard carbon negative electrode material with a volume average particle di...

Embodiment 3

[0038] ①Add refined anthracene and paraformaldehyde into the reaction kettle with a mass ratio of 10:3 and mix them under stirring, and carry out cross-linking polymerization reaction at 100°C for 4 hours; ②After the reaction is completed, it will not melt at 600°C under an inert atmosphere Treat for 2 hours, cool down to room temperature and discharge, then pulverize with a pulverizer at a speed of 1000 rpm, pass through a 60-mesh sieve, take the undersieve and put it into a well-type carbonization furnace, and carry out pre-carbonization treatment at 750°C under an inert atmosphere 8 hours, down to room temperature; ③Use a pulverizer to crush at a speed of 8000 rpm, pass through a 60-mesh sieve, and take the under-sieve and heat-treat at 1100°C for 24 hours in a high-temperature carbonization furnace of a pusher kiln under an inert atmosphere; ④Through air flow Grinding and classifying machine crushing and grading are carried out with a compressed air pressure of 9 MPa, a fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com