Preparation method of graphene-like carbon nitride photocatalytic material

A technology of carbon nitride light and graphite carbon nitride, which is applied in the field of preparation of graphene-like carbon nitride photocatalyst, can solve the problem of low light utilization rate, and achieve good photocatalytic degradation of environmental pollutants and photocurrent The effect of responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Graphene-like C prepared by exfoliation 3 N 4

[0025] Weigh 0.06g g-C 3 N 4 Place in a 50 ml beaker, add 25 ml 99% 1,3-butanediol, then put it into a 100W ultrasonic wave for 30 hours, then centrifuge the suspoemulsion at 13000 rpm for 5 After 10 minutes, the obtained suspoemulsion was transferred to a watch glass, placed in a constant temperature oven, and evaporated to dryness at 160 ° C. The finally obtained light yellow solid powder was graphene-like carbon nitride.

Embodiment 2

[0026] Example 2: Graphene-like C prepared by exfoliation 3 N 4

[0027] Weigh 0.08 g g-C 3 N 4 Place in a 50 ml beaker, add 40ml of 40% 1,3-butanediol, then put it into an 800W ultrasonic wave for 7 hours, then centrifuge the suspoemulsion at 1500 rpm for 20 minutes , transfer the obtained suspoemulsion to a watch glass, put it into a constant temperature oven, and evaporate to dryness at 100°C, and the finally obtained light yellow solid powder is graphene-like carbon nitride.

Embodiment 3

[0028] Embodiment 3: the graphene-like C prepared by exfoliation 3 N 4

[0029] Weigh 0.1g g-C 3 N 4 Place in a 50 ml beaker, add 30 ml of 70% 1,3-butanediol, then put it into a 400 W ultrasonic wave for 15 hours, then centrifuge the suspoemulsion at 9000 rpm After 10 minutes, the obtained suspoemulsion was transferred to a watch glass, placed in a constant temperature oven, and evaporated to dryness at 300°C. The finally obtained light yellow solid powder was graphene-like carbon nitride.

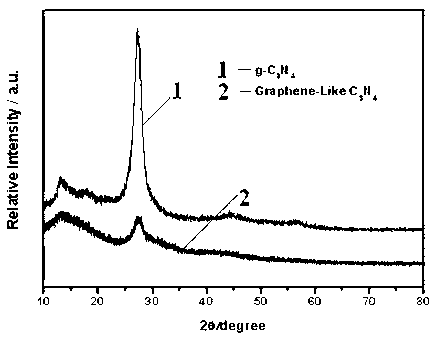

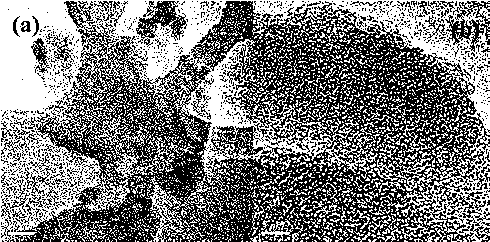

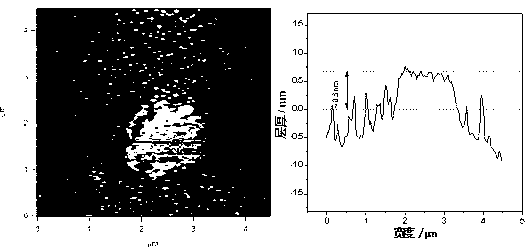

[0030] The structure test of the prepared graphene-like carbon nitride was carried out on a German Bruker D8 type ray diffractometer (XRD) (Cu-Kα ray, λ=1.5418?, the range is 10 ° -80 ° ), and its XRD pattern is shown in figure 1 shown. Depend on figure 1 It can be seen that g-C 3 N 4 in 13.1 ° and 27.4 ° Diffraction peaks appear. and g-C 3 N 4 Compared to graphene-like carbon nitride in 13.1 ° and 27.4 ° The intensity of the diffraction peaks is significantly weakened, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com