Method for preparing large-size analcite by utilizing hydrothermal crystallization of geopolymer

A geopolymer and hydrothermal crystallization technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of difficult-to-form analcime products and low sales of synthetic products, and achieve the effects of low cost, wide range of raw materials, and broadened application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

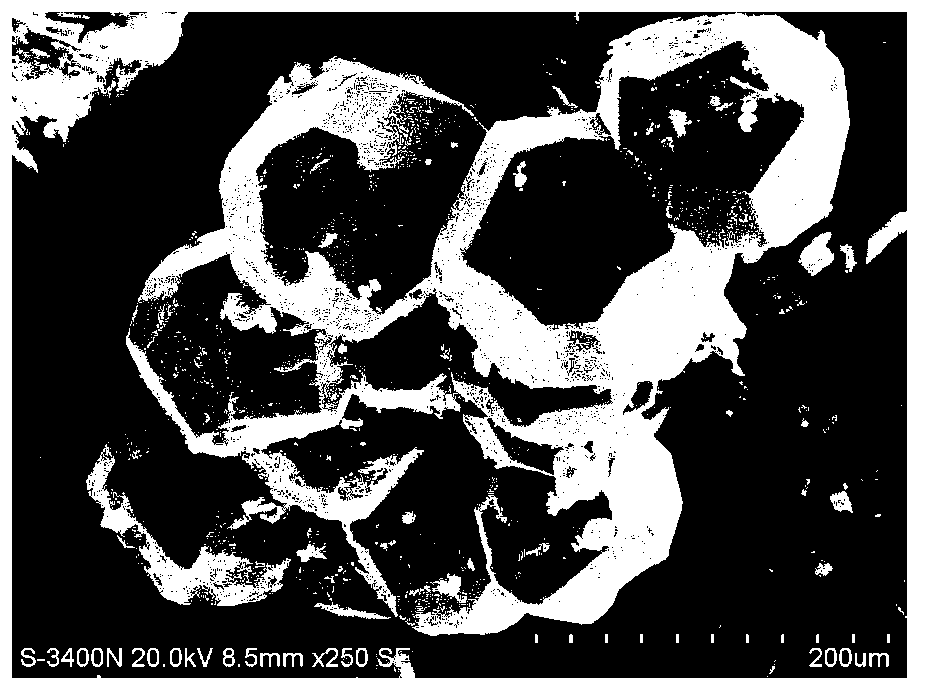

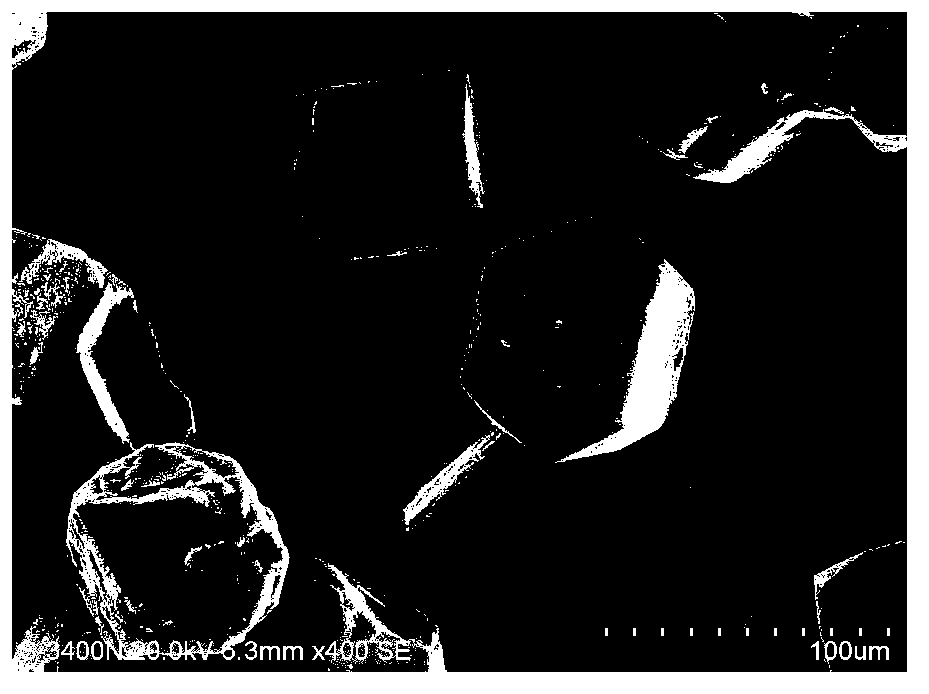

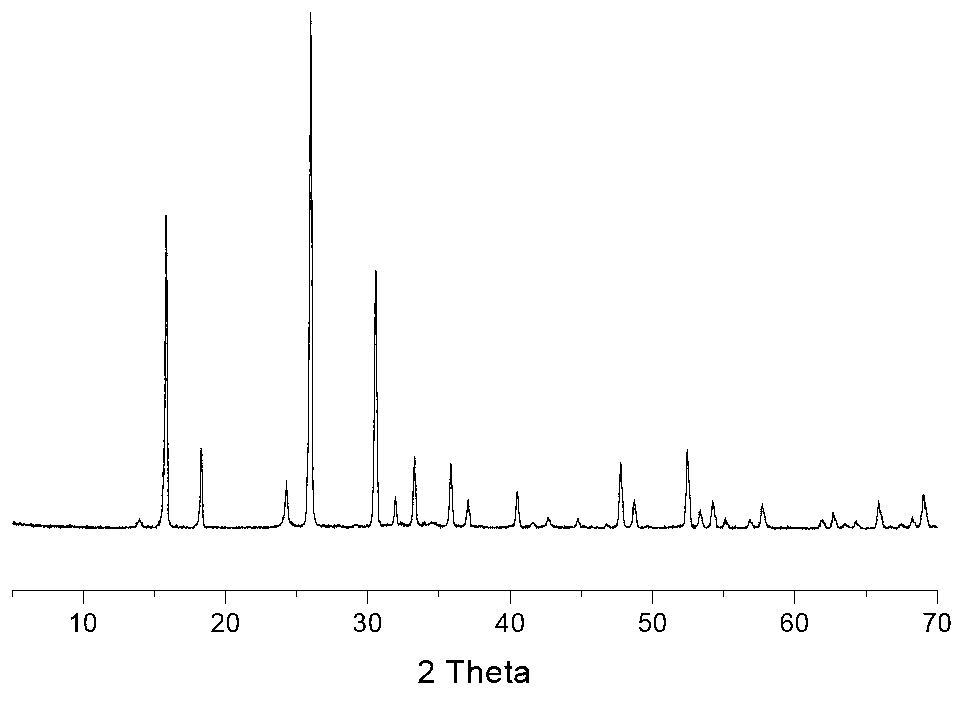

[0026] Method for preparing large-size analcime by hydrothermal crystallization of geopolymer

[0027] 1.Al 2 o 3 -SiO 2 Powder preparation:

[0028] Aluminum chloride and absolute ethanol were mixed with a molar ratio of 1:4 and magnetically stirred for 12 hours to prepare an aluminum sol for use, and ethyl orthosilicate and anhydrous ethanol were mixed with a molar ratio of 1:16 and magnetically stirred for half an hour to prepare a silicon sol. The sol is ready for use. Add aluminum sol dropwise to the stirring silica sol to prepare a composite sol with a silicon-aluminum ratio of 1:2, continue stirring for 2 hours, put it in a constant temperature water bath at 70°C until a transparent and uniform gel appears, and age at room temperature for 36 hours , dried at 105°C for 12 hours, ground, and calcined at 800°C for 2 hours to obtain amorphous Al 2 o 3 -SiO 2 The powder is ready for use.

[0029] 2. Preparation of geopolymer samples:

[0030] molar ratio SiO 2 / Al ...

Embodiment 2

[0035] Method for preparing large-size analcime by hydrothermal crystallization of geopolymer

[0036] 1.Al 2 o 3 -SiO 2 Powder preparation:

[0037] Mix aluminum nitrate and absolute ethanol with a molar ratio of 1:4 and magnetically stir for 12 hours to prepare aluminum sol for use, and mix ethyl orthosilicate and absolute ethanol with a molar ratio of 1:16 for half an hour to prepare silica sol stand-by. Add aluminum sol dropwise to the stirring silica sol to prepare a composite sol with a silicon-aluminum ratio of 1:2, continue stirring for 2 hours, put it in a constant temperature water bath at 70°C until a transparent and uniform gel appears, and age at room temperature for 36 hours , dried at 105°C for 12 hours, ground, and calcined at 800°C for 2 hours to obtain amorphous Al 2 o 3 -SiO 2 The powder is ready for use.

[0038] 2. Preparation of geopolymer samples:

[0039] molar ratio SiO 2 / Al 2 o 3 =4, Na 2 O / Al 2 o 3 =1,H 2 O / Na 2 O=7 to prepare geopo...

Embodiment 3

[0044] Method for preparing large-size analcime by hydrothermal crystallization of geopolymer

[0045] 1.Al 2 o 3 -SiO 2 Powder preparation:

[0046] Same as instance 2:

[0047] 2. Preparation of geopolymer samples:

[0048] molar ratio SiO 2 / Al 2 o 3 =4, Na 2 O / Al 2 o 3 =1,H 2 O / Na 2 O=10 to prepare geopolymers. Weigh Al according to the ratio 2 o 3 -SiO 2 Powder and water glass with a modulus of 0.9 (the water glass has been left to stand for 24 hours), adjust the H with deionized water 2 O / Na 2 O=10; then pour it into the mold after stirring in a constant temperature mixer for 2 minutes, maintain at 60°C for 24 hours, and demould to obtain a geopolymer test block with a certain strength.

[0049] 3. Preparation of large size analcime:

[0050] Put the geopolymer test block with a certain strength obtained in the above step into a hydrothermal kettle, add deionized water with 60% of the volume of the hydrothermal kettle, and prepare it under hydrothermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystal size | aaaaa | aaaaa |

| Crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com