Method for biological treatment of sulfate wastewater employing synchronous electric catalysis of anode and cathode

An electrocatalytic sulfate and biological treatment technology, which is applied in the field of resource treatment of sulfate wastewater, can solve the problems of low utilization rate of electrocatalytic electric energy and no use of electric field anodes, etc., and achieve the effect of increasing the rate and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

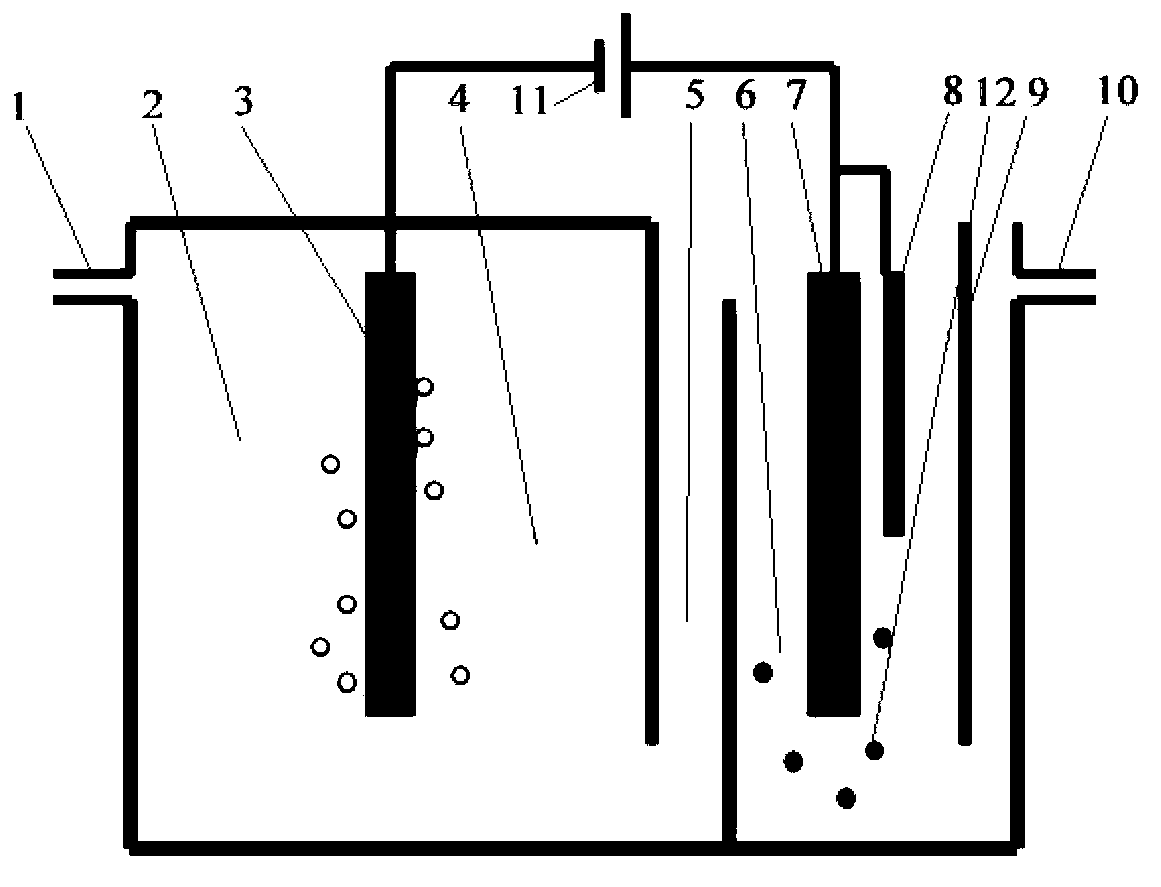

Image

Examples

Embodiment 1

[0059] This example is a process of using an electrocatalytic bioreactor to treat 7-ACA pharmaceutical wastewater.

[0060] The characteristics of the treated 7-ACA pharmaceutical wastewater are as follows:

[0061] Wastewater pH: 8.02~8.29, SO 4 2- : 1800~3200mg / L, COD: 6000~8000mg / L, NH 4 -N: 700-800mg / L.

[0062] Steps to treat 7-ACA pharmaceutical wastewater:

[0063] (1) Before the wastewater continuously enters the electrocatalytic bioreactor, microorganisms are inoculated into the cathode reaction area and the anode reaction area of the reactor respectively, and the microorganisms in the cathode and anode reaction areas of the electric field are activated independently at the same time. The microorganisms inoculated in the cathode reaction zone are mainly Desulfovibriosp., and the microorganisms inoculated in the anode reaction zone are mainly Thiobacillus thioparus;

[0064] (2) The culture medium in the cathode reaction zone is configured with ultrapure water, ...

Embodiment 2

[0074] This embodiment is the process of using an electrocatalytic biological reaction device to treat acid mine wastewater.

[0075] The characteristics of the treated acid mine wastewater are as follows:

[0076] Wastewater pH: 3.00~3.46, SO 4 2- : 6000~8000mg / L, COD4 -N: 35-50 mg / L.

[0077] Steps for treating acid mine wastewater:

[0078] (1) Before the wastewater continuously enters the electrocatalytic bioreactor, microorganisms are inoculated into the cathode reaction area and the anode reaction area of the reactor respectively, and the microorganisms in the cathode and anode reaction areas of the electric field are activated independently at the same time. The microorganisms inoculated in the cathode reaction zone are mainly Desulfovibriosp., and the microorganisms inoculated in the anode reaction zone are mainly Thiobacillus thioparus;

[0079] (2) The culture medium in the cathode reaction zone is configured with ultrapure water, and the composition of the cul...

Embodiment 3

[0090] This embodiment is the process of using an electrocatalytic biological reaction device to treat monosodium glutamate wastewater.

[0091] The characteristics of MSG wastewater treated are as follows:

[0092] Wastewater pH: 6.5~6.8, SO 4 2- : 12000~15000mg / L, COD: 10000mg / L.

[0093] Steps to treat MSG wastewater:

[0094] (1) Before the wastewater continuously enters the electrocatalytic bioreactor, microorganisms are inoculated into the cathode reaction area and the anode reaction area of the reactor respectively, and the microorganisms in the cathode and anode reaction areas of the electric field are activated independently at the same time. The microorganisms inoculated in the cathode reaction zone are mainly Desulfovibriosp., and the microorganisms inoculated in the anode reaction zone are mainly Thiobacillus thioparus;

[0095] (2) The culture medium in the cathode reaction zone is configured with ultrapure water, and the composition of the culture medium is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com