Blower pitch bearing lubricating grease and preparation method thereof

A bearing lubrication and fan technology, applied in the field of lubricating grease, can solve the problems of short oil life, non-biodegradable, environmental pollution, etc., achieve high and low temperature performance balance, improve comprehensive performance, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

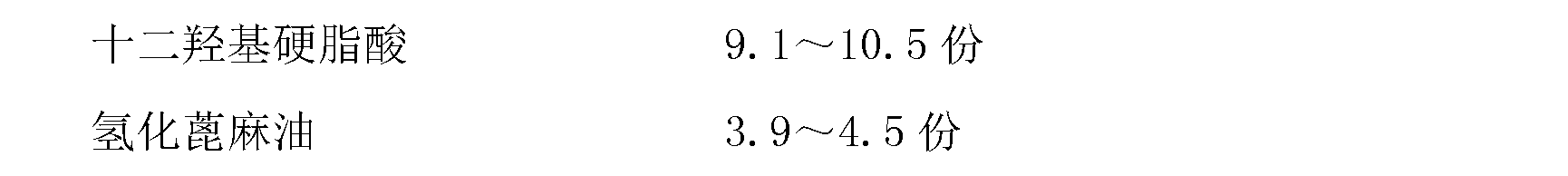

[0032] A kind of lubricating grease for wind turbine variable pitch bearings, comprising the following components in parts by weight:

[0033]

[0034] The preparation method of fan variable pitch bearing lubricating grease comprises the following steps:

[0035] 1) Add 50-55% base oil into the saponification kettle, start heating and stirring, and the speed is 30-60 rpm;

[0036] 2) Dissolve lithium hydroxide in water, the amount of water is 6 to 6.5 times the amount of lithium hydroxide, and add the lithium hydroxide aqueous solution into the saponification kettle;

[0037] 3) Add hydrogenated castor oil to the saponification kettle at 80-105°C for 20 minutes;

[0038] 4) At 105±2°C, add lauryl hydroxystearic acid into the saponification kettle for saponification for 50-60 minutes, continue heating and dehydration;

[0039] 5) Add 20-25% base oil to the saponification kettle at 140-145°C, continue heating to 205-210°C, add octyl-butyl diphenylamine, and keep warm for 5-...

Embodiment 2

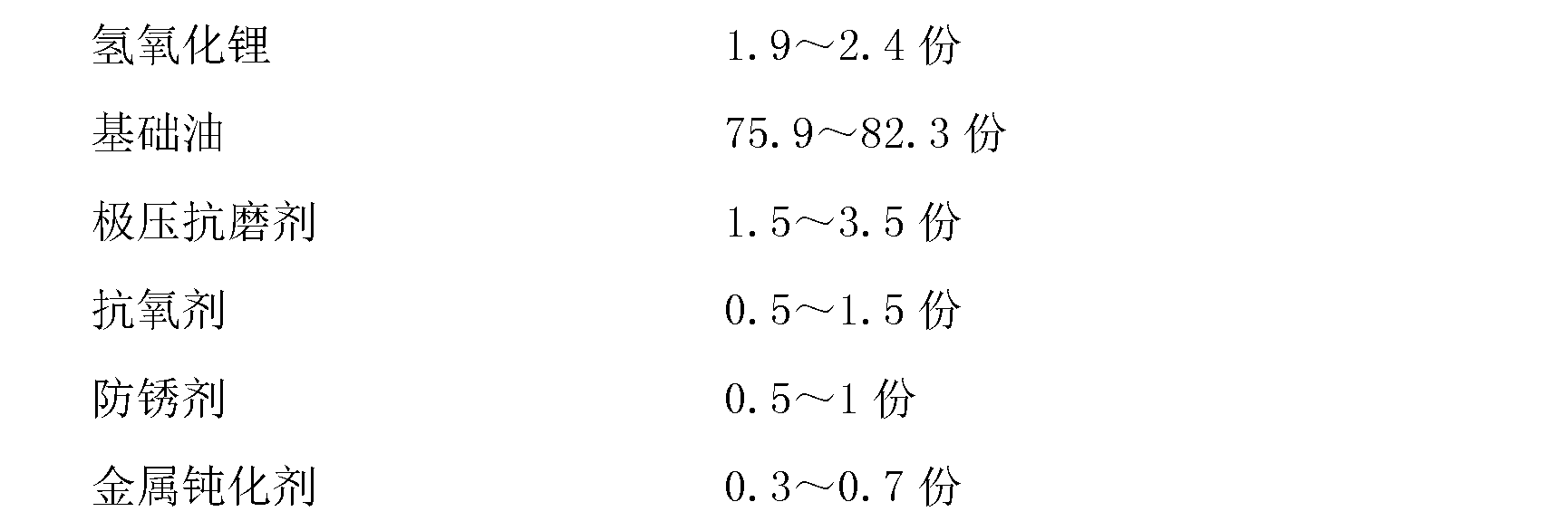

[0044] Fan variable pitch bearing lubricating grease is characterized in that the weight ratio of each component is as follows:

[0045]

[0046] The preparation method of the fan variable pitch bearing lubricating grease is the same as the first embodiment.

Embodiment 3

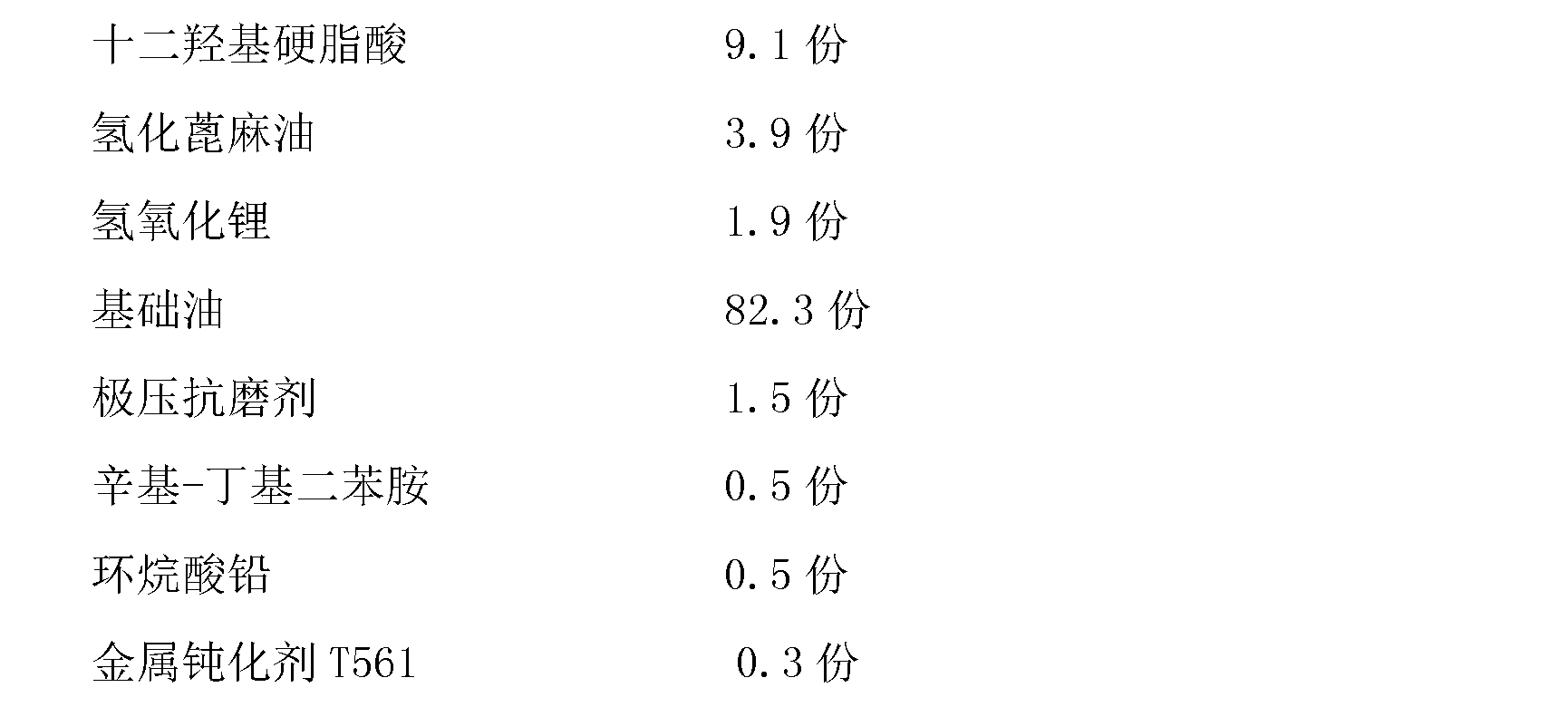

[0048] Fan variable pitch bearing lubricating grease is characterized in that the weight ratio of each component is as follows:

[0049]

[0050] The preparation method of the fan variable pitch bearing lubricating grease is the same as the first embodiment.

[0051] The above base oil is a mixed oil of low viscosity polyalphaolefin and alkyl naphthalene, and the kinematic viscosity of this mixed oil is about 30mm at 40°C 2 / s, the viscosity index is not less than 130.

[0052] The above-mentioned extreme pressure antiwear agent is a mixture of thiourethane, triphenyl thiophosphate and dibutyl dithioamino molybdenum oxysulfide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com