High-efficiency combined corn stalk processing method

A corn stalk and combined processing technology, applied in fermentation and other directions, can solve the problems of incomplete destruction of cell wall barrier structure, threat to human health, waste of environment, etc., achieve important promotion and application value, and overcome technical thresholds that are difficult to transform and utilize efficiently Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

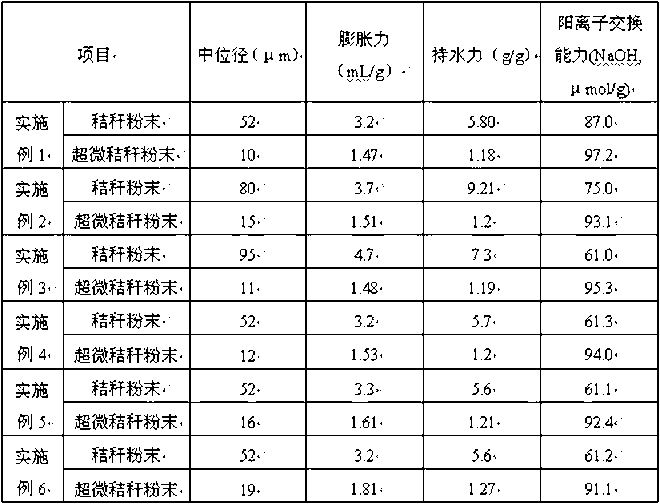

Embodiment 1

[0018] Take 25 kg of corn stalks, use a shredder to cut it into flake pieces with a length of 2 cm, a width of 1 cm, and a thickness of 0.5 cm; use a micro pulverizer to crush the flakes into 52 μm straw powder; use a ball mill to grind the above straw powder 16 minutes, the rotating speed is 1350rpm, until it is ground into ultrafine straw powder with a particle size of 10 μm.

Embodiment 2

[0020] Take 15 kg of corn stalks, cut them into 1 cm long, 1.5 cm wide, and 0.63 cm thick flaky pieces with a shredder; use a micro pulverizer to crush the flaky pieces into 80 μm straw powder; use a ball mill to grind the above stalks The powder was ground for 12 minutes at a rotational speed of 1050 rpm until it was ground into ultrafine straw powder with a particle size of 15 μm.

Embodiment 3

[0022] Take 10 kg of corn stalks, cut them into 1.5 cm long, 0.5 cm wide, and 0.2 cm thick flaky fragments with a shredder; crush the flaky fragments into 95 μm straw powder with a micro pulverizer; use a ball mill to grind the above straw The powder was ground for 8 minutes at a rotational speed of 1200 rpm until it was ground into an ultrafine straw powder with a particle size of 11 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com