Capacitance-type ultrasonic sensor of integrated full-vibration conductive film structure and manufacturing method thereof

A technology of ultrasonic sensor and conductive film, which is applied in the field of ultrasonic sensor, can solve the problems of high frequency of sensing diaphragm, small acoustic-electric conversion capability, difficulty in film release, etc., and achieves small device frequency deviation, high response sensitivity, and adjustable thickness. high control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing:

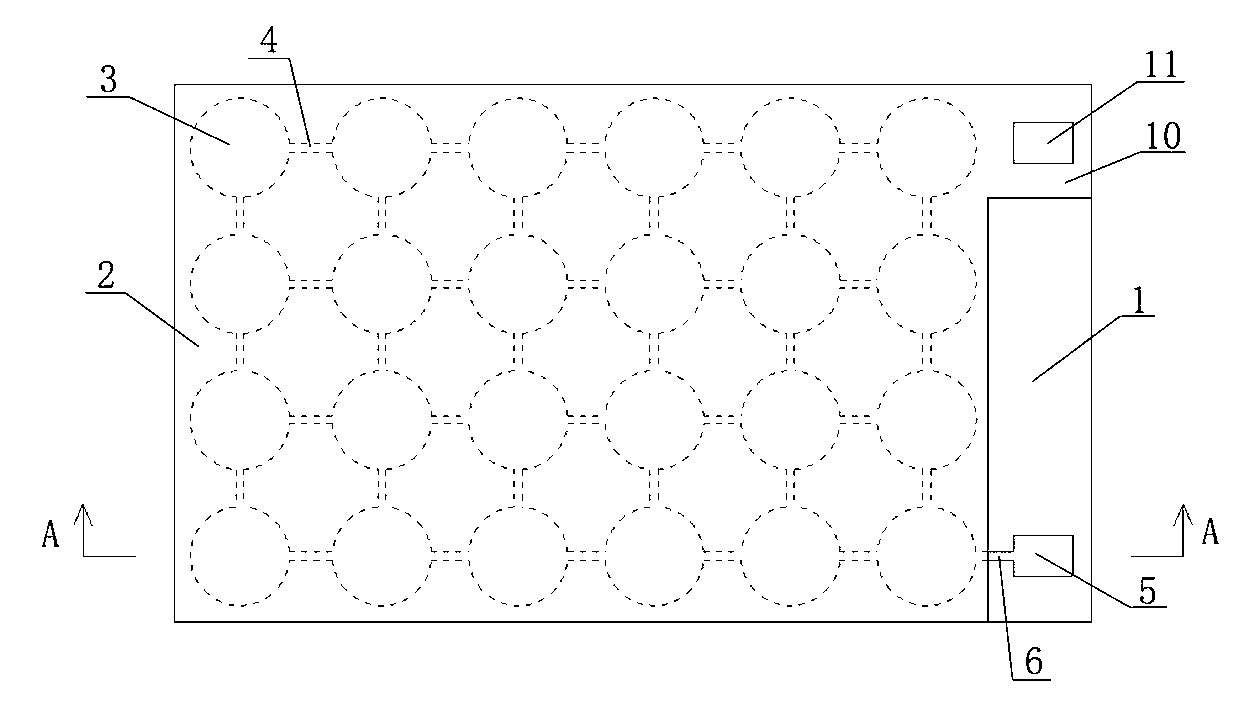

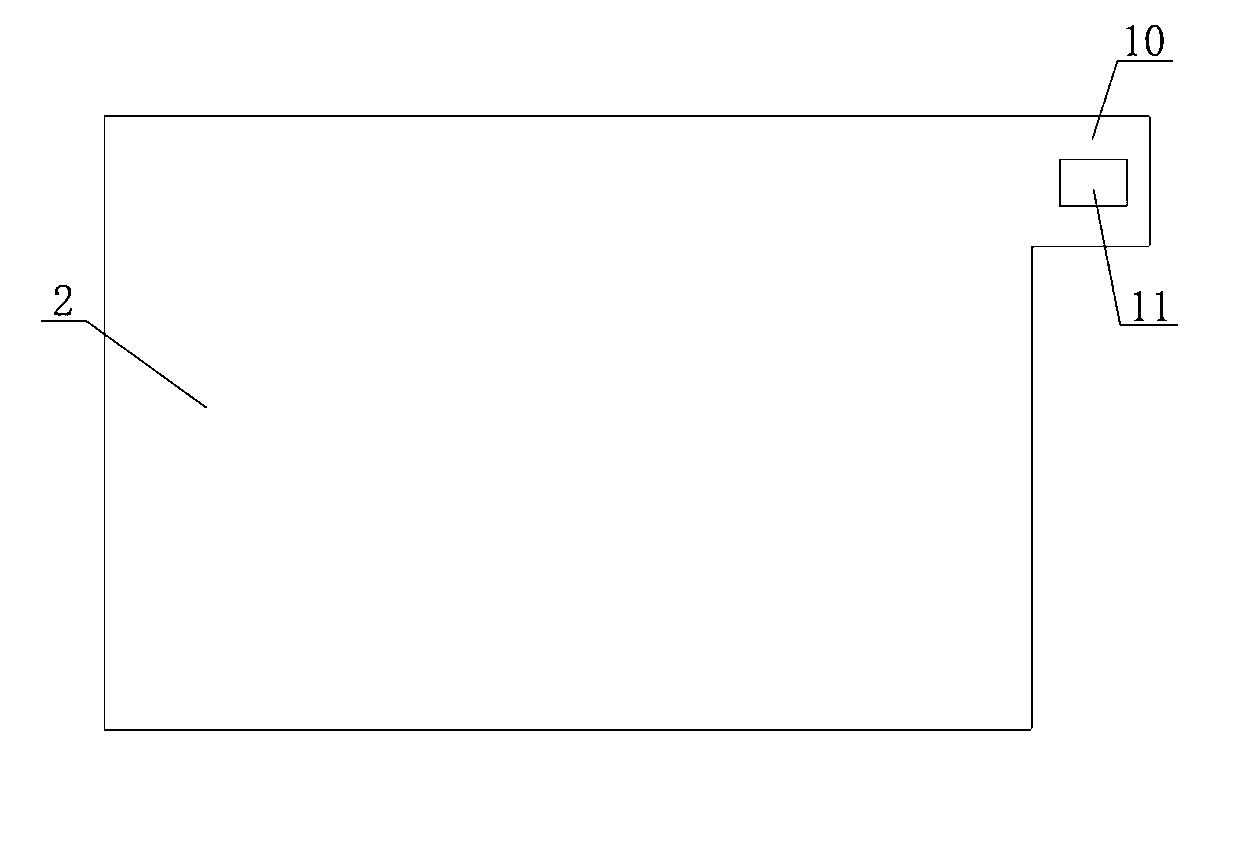

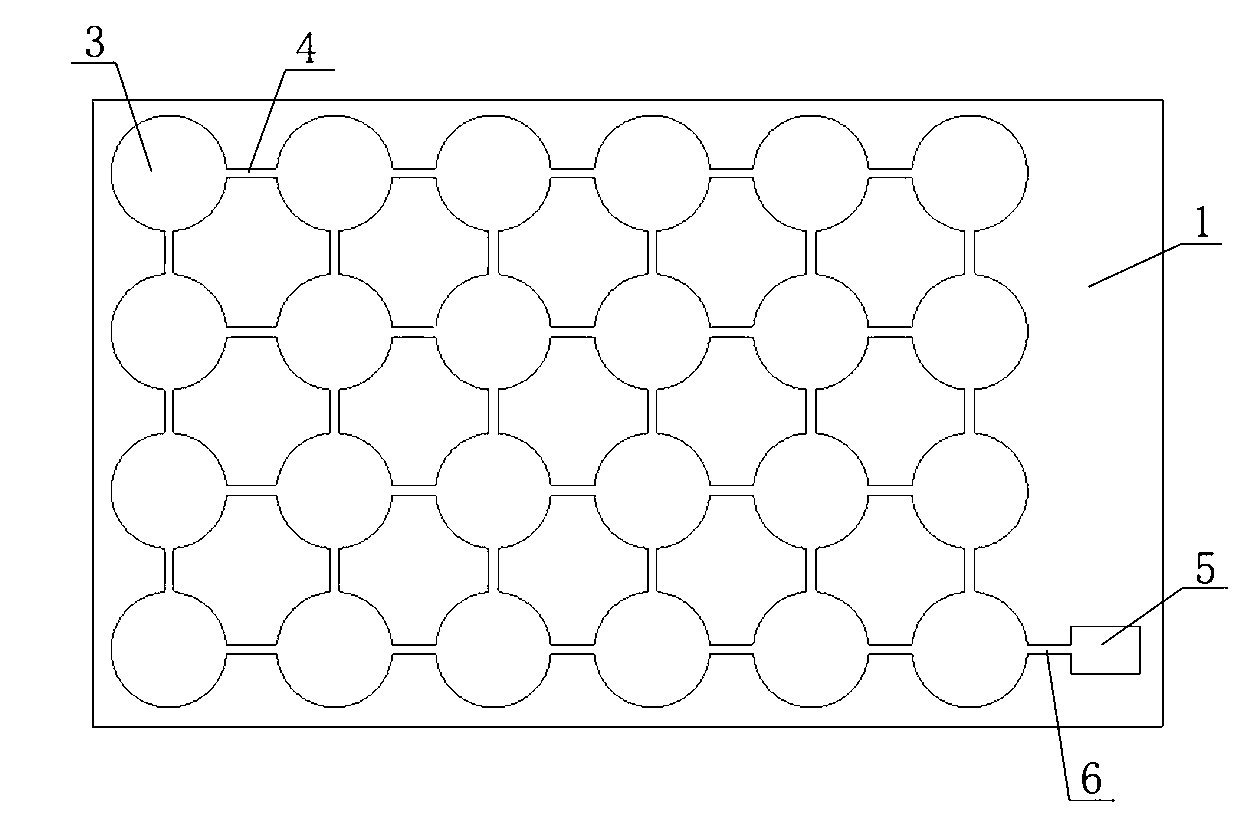

[0049] Such as Figure 1 to Figure 4 As shown, a capacitive ultrasonic sensor with an integrated full-vibration conductive thin film structure includes a silicon substrate 1 and a full-vibration thin film 2; the upper surface of the silicon substrate 1 is provided with a number of cylindrical microstructure cavities 3, and several cylindrical microstructure cavities The structural cavities 3 are aligned in rows and columns, and between two adjacent cylindrical microstructure cavities 3 in each row and between two adjacent cylindrical microstructure cavities 3 in each row are formed by opening a first groove 4. The depth of the cylindrical microstructure cavity 3 is the same as the depth of the first groove 4; a lower electrode lead-out cavity 5 is also opened on the edge of the upper surface of the silicon substrate 1, and the lower electrode lead-out cavity 5 is connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com