Method for preparing diamond base FET device with T-similar-type grid shelter autocollimation technology

A diamond, self-aligned technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., to solve problems such as increased resistance and decreased frequency performance of transistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

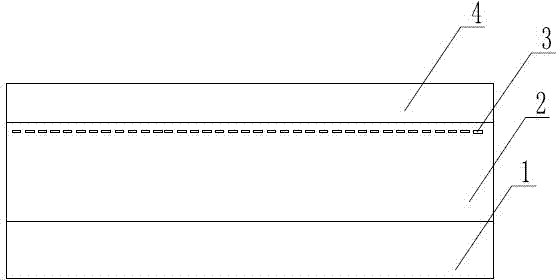

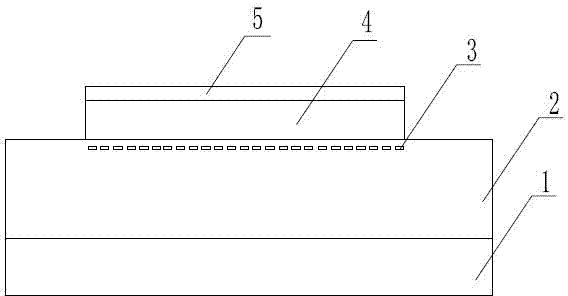

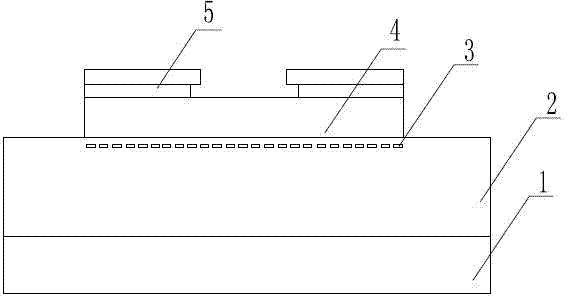

[0046] Example 1: (1) Using a microwave plasma chemical vapor deposition device to grow a high-resistance polycrystalline diamond of 300 μm on a molybdenum substrate; (2) Using hydrogen plasma for 30 minutes to form a p-type conductive channel on a high-resistance diamond material ; (3) Cover a layer of Au mask layer on the surface of the diamond material with a thickness of 2 μm; (4) Photolithography table; (5) Use KI+I 2 After the etching solution removes the Au mask in the area outside the mesa, use oxygen plasma etching equipment to etch for 2 minutes to achieve mesa isolation; (6) photolithographically etch the gate on the gold mask layer; (7) use KI to etch (8) Make a T-like gate in the above corrosion area, and the gate metal is Al; (9) The outer layer of the Al gate is oxidized in the air to form Al 2 o 3 (10) Using a T-shaped gate as a mask, using a self-alignment process, evaporating Au with a thickness of 5nm, self-aligning outside the shadow under the gate cap to ...

Embodiment 2

[0047] Example 2: (1) Using a microwave plasma chemical vapor deposition device to grow a high-resistance polycrystalline diamond of 300 μm on a molybdenum substrate; (2) Using hydrogen plasma for 30 minutes to form a p-type conductive channel on a high-resistance diamond material ; (3) Cover a layer of Ti mask layer on the surface of the diamond material, with a thickness of 2 μm; (4) Photolithographic mesa; (5) After removing the Ti mask in the area outside the mesa with hydrofluoric acid solution, use oxygen plasma etching equipment Etching is performed for 2 minutes to achieve mesa isolation; (6) Photoetching the gate on the Ti mask layer; (7) Using hydrofluoric acid solution to remove the Ti mask in the middle region of the source and drain; (8) In the above-mentioned etched area To make a T-like grid, the gate metal is Al; (9) the outer layer of the Al grid is oxidized in the air to form Al 2 o 3(10) Using a T-like gate as a mask, using a self-alignment process, evapora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com