A device for treating benzene-containing waste gas by particle group electrode adsorption coupled with electrocatalytic oxidation

A particle swarm electrode, catalytic oxidation technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of small processing capacity per unit cell, low current efficiency, etc., and achieve low operating costs and current efficiency. improve, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

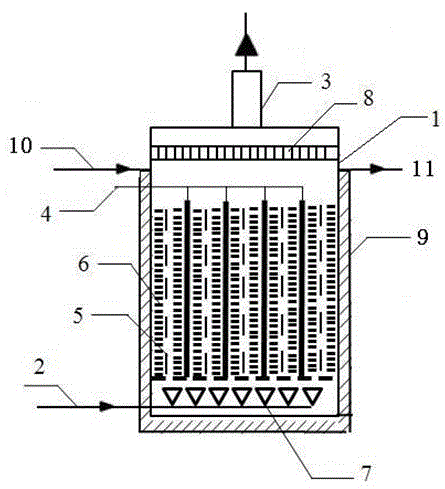

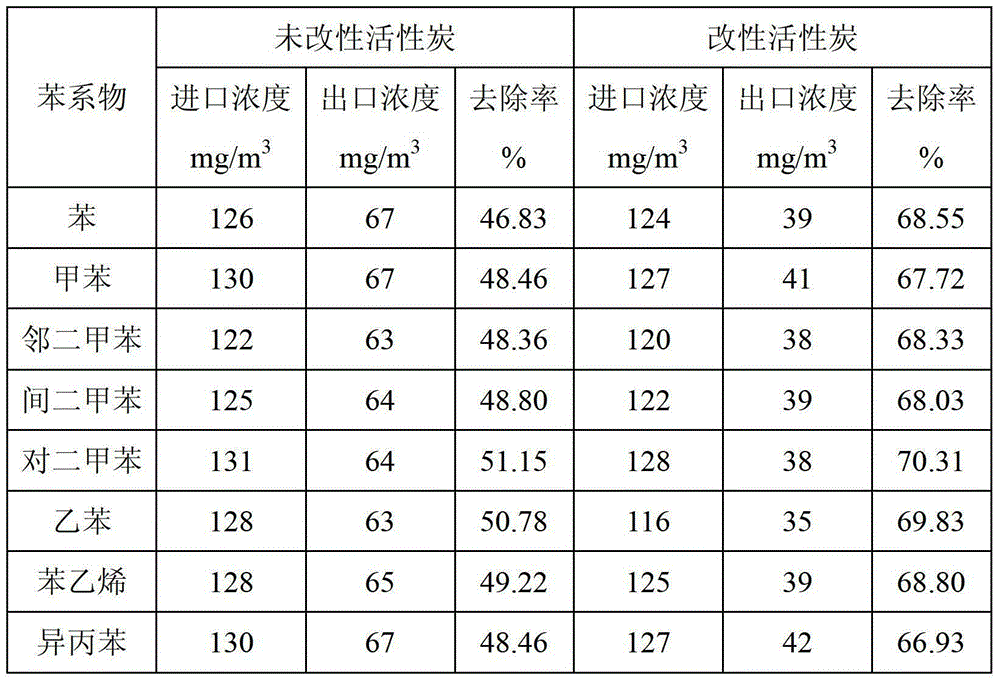

[0023] The size of the built-in electrolytic reactor of this device is 500mm×500mm×1000mm, which is composed of 9 sets of unit reactors. The positive conductive plate is composed of 9 Ti electrodes, and the distance between the positive conductive plates is 100mm. The negative conductive plate is stainless steel mesh, and the electrode mesh is Both are 2mm×2mm. The positive electrode conductive plate and the negative electrode conductive plate are placed vertically, and the stainless steel mesh surrounds the positive electrode conductive plate. The space between the positive conductive plate and the negative conductive plate is filled with a particle group electrode mixed with modified activated carbon particles with a diameter of 10mm and soft polyvinyl chloride. The electrolyte is a sodium sulfate solution with a mass concentration of 5%. For comparison, the particle group electrode is filled with unmodified activated carbon in the same device. The gas flow rate was 20m3 / h;...

Embodiment 2

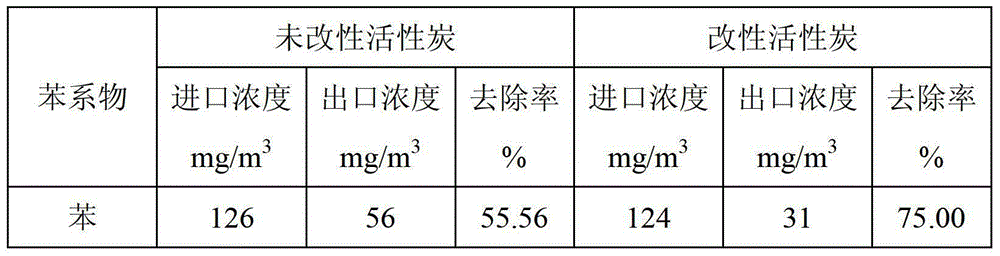

[0027] The size of the built-in electrolytic reactor of this device is 500mm×500mm×1000mm, which is composed of 9 sets of unit reactors. The positive conductive plate is composed of 9 Ti electrodes, and the distance between the positive conductive plates is 100mm. The negative conductive plate is stainless steel mesh, and the electrode mesh is Both are 2mm×2mm. The positive electrode conductive plate and the negative electrode conductive plate are placed vertically, and the stainless steel mesh surrounds the positive electrode conductive plate. The space between the positive conductive plate and the negative conductive plate is filled with a particle group electrode mixed with modified activated carbon particles with a diameter of 10mm and soft polyvinyl chloride. The electrolyte is a sodium sulfate solution with a mass concentration of 5%. For comparison, the particle group electrode is filled with unmodified activated carbon in the same device. Set DC voltage 10V, current 6...

Embodiment 3

[0032] The device setting and control conditions of this embodiment are the same as those of Embodiment 2, the difference is that the positive conductive plates are respectively Ti electrodes, SnO 2 / Ti electrode, IrO 2 / Ti electrode, MnO 2 / Ti electrode, PbO 2 / Ti electrode. The influence of different positive electrode conductive plates on the removal effect of benzene series was tested under the same conditions. The test results are shown in Table 3. The results show that the metal oxide composite electrode has a better removal effect than the pure Ti electrode, while the IrO 2 / Ti electrode and MnO 2 / Ti electrode has a better removal effect than the other two metal oxide electrodes.

[0033] table 3

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com