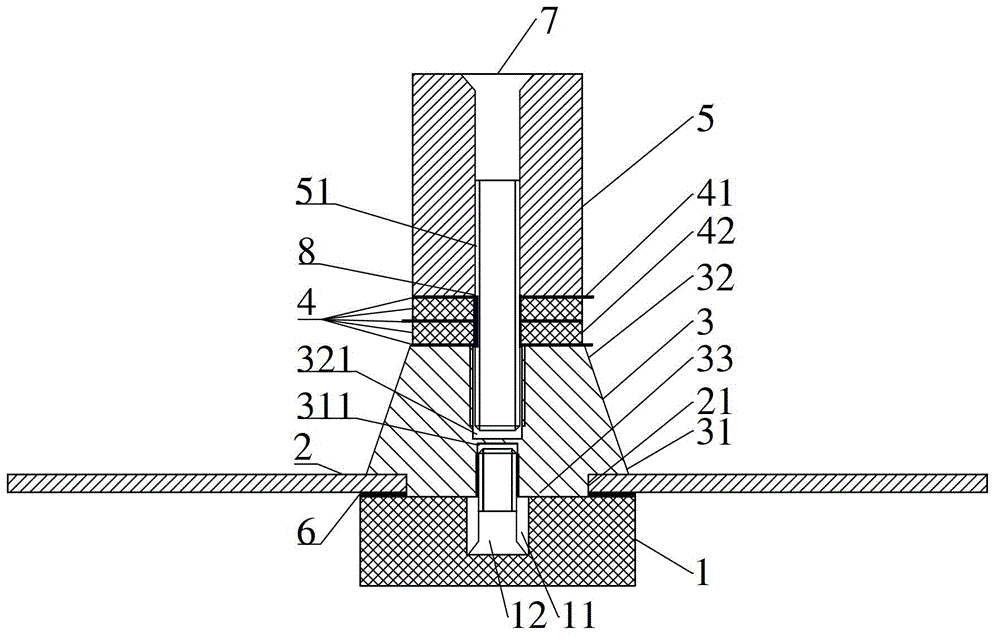

Ultrasonic transducer used in strong-acid environment

An ultrasonic and strong acidic technology, applied in the direction of fluid using vibration, etc., can solve problems such as corrosion of the transmitting end of the stainless steel sound field, achieve the effects of reducing labor costs, improving liquid delivery efficiency, and facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

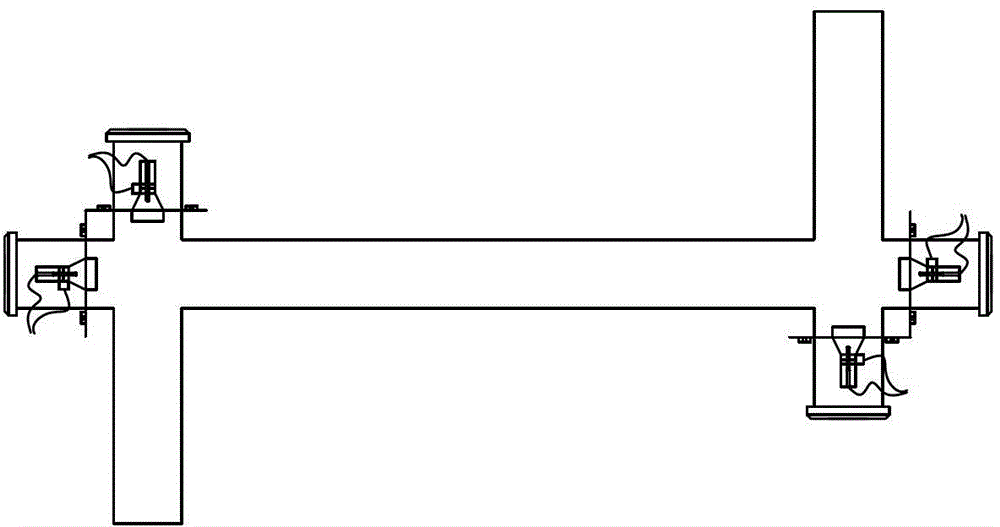

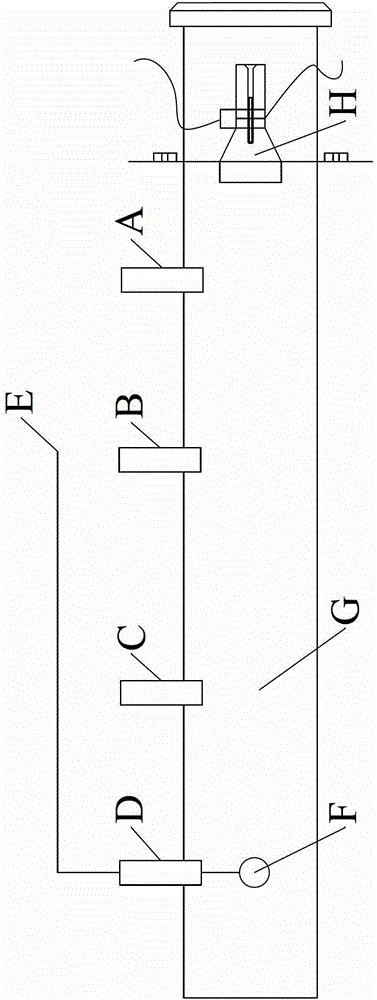

[0038] In order to compare the ultrasonic transducer of the present invention with the ultrasonic emission effect of the common stainless steel plate transmitting head transducer, the connection mode of its testing device is as follows image 3 shown. According to the industrial production conditions of a zinc industry group company, we designed a set of static pipeline ultrasonic field strength testing system. The equipment includes: F40 digital synthetic function signal generator, power amplifier (HSA4011), ultrasonic transducer, 3770mm long polyethylene pipe, digital oscilloscope (TDS2024), and ultrasonic probe. The system is used to test and compare the ultrasonic emission intensity of the ultrasonic transducer of the present invention and the common stainless steel plate emitting head transducer. For the convenience of characterization, the size, transmission power and operating frequency of the two ultrasonic transducers are selected to be the same.

[0039] Ceramic ul...

Embodiment 2

[0047] In this embodiment, the influence of the diameter of the boss at the thick end of the frustum-shaped waveguide on the transmission of ultrasonic intensity is compared, and the connection method of the test device is as follows: image 3 shown. The diameter of the boss should not be too small: because the acoustic impedance Z of plastic (take polyethylene as an example), aluminum, and ceramics is about 4.0078g / cm 2 s, 81.7g / cm 2 s, 87.04g / cm 2 s, the acoustic impedance of polyethylene is quite different from that of aluminum and ceramics, and the plastic support plate is placed between the cone-shaped waveguide and the ceramic ultrasonic transmitter to form two acoustic reflection interfaces, which directly affect the transmission of ultrasonic waves. . The diameter of the boss is small, and the transmission effect of the ultrasonic intensity is not good. The diameter of the boss should not be too large, otherwise the effective area of the acid-proof gasket is smal...

Embodiment 3

[0053] Prepare 0.05mol / L, 0.1mol / L, 0.2mol / L, 0.5mol / L, 1.0mol / L H 2 SO 4 , HCl, HNO 3 Aqueous solution, the zinc sulfate aqueous solution in embodiment 1 is changed into the H of different acidity 2 SO4 , HCl, HNO 3 water solution, and then connect the ultrasonic descaler with the ultrasonic generator for a one-month test. The connection method of the test device is as follows: image 3 shown. One month later, the ultrasonic descaling device was disassembled, and the corrosion degree of the ceramic ultrasonic emitting head of the ultrasonic transducer composite emitting head device was observed. The results showed that the surface of the ceramic ultrasonic emitting head in the strong acidic aqueous solution of 0.05mol / L was smooth, Not corroded; 0.1mol / L strong acidic aqueous solution of ceramic ultrasonic transmitter surface is smooth, not corroded; 0.2mol / L strong acidic aqueous solution of ceramic ultrasonic transmitter surface is smooth, not corroded; 0.5mol / L The su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com