Compound flame-retardant polystyrene composition and preparation method thereof

A technology of polystyrene and compound flame retardant, which is applied in the field of polystyrene composition modified by compound flame retardant and its preparation, can solve the problem of insufficient structural strength of carbon layer, low melting of ammonium polyphosphate, and inability to Continue to protect the internal matrix and other issues to achieve the effect of improved efficiency, low cost and high flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

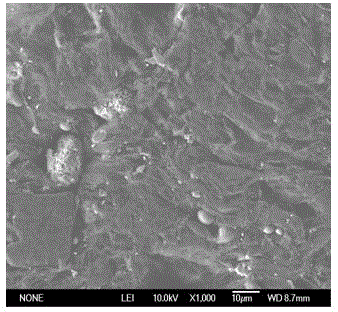

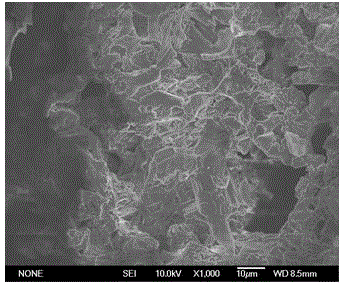

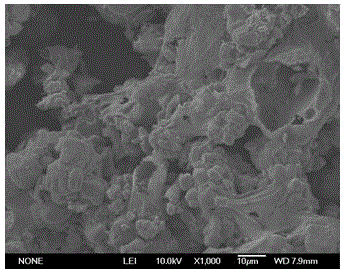

Image

Examples

specific Embodiment approach 1

[0034] Implement a composite flame-retardant polystyrene composition, the composition and content of the composition are as follows in parts by mass:

[0035] 100 parts of polystyrene resin, the polystyrene resin is one of polystyrene and high-impact polystyrene.

[0036] 30~70 parts of compound flame retardant, the composition and content of the compound flame retardant are according to the mass ratio: ammonium polyphosphate: expanded graphite: calcium carbonate: char formation accelerator = 55:25:15:5: 3, and add a surfactant whose mass fraction accounts for 1-3% of the total compound flame retardant, and fully mix to form.

[0037] Wherein, the degree of polymerization of the ammonium polyphosphate is n≥1000, and the particle size is 80-200 mesh; the particle size of the expanded graphite is 80-200 mesh, and the expansion ratio is 0.15-0.25 m 3 / kg; the calcium carbonate is light calcium carbonate; the char-forming accelerator is one of zinc oxide, zinc borate and magnesiu...

specific Embodiment approach 2

[0042] Implement the preparation method of above-mentioned a kind of composite flame retardant polystyrene composition, its described preparation method is carried out according to the following steps:

[0043] Step 1. Dry the polystyrene resin at 100-140°C for 3-4 hours to control the moisture content below 0.03% to obtain a dry polystyrene resin.

[0044] Step 2. Composite flame retardant: the composition and its content by mass ratio are: ammonium polyphosphate: expanded graphite: calcium carbonate: char formation accelerator = 30~70: 10~50: 10~25: 3~5 The composition is mixed, mixed and surface treated at 90~130°C, 800~1000r / min high-speed stirring for 3~4min, adding 1~3% of the total mass of the compound flame retardant Surfactant, continue to mix 5~8min, dry to obtain compound flame retardant.

[0045] Step 3, the above step (1) dry polystyrene resin and the above step (2) compound flame retardant, and lubricating dispersant, toughening agent and antioxidant are respec...

Embodiment 1

[0050] Implement the preparation method of a kind of composite flame-retardant polystyrene composition provided by the present invention as follows:

[0051] The composition and content of the compound flame retardant polystyrene composition are as follows: 100g polystyrene resin, 30g compound flame retardant, 2g stearic acid, 6g toughening agent EMA, 3g antioxidant 164.

[0052] Among them, the compound flame retardant is 21g of ammonium polyphosphate, 4.5g of expanded graphite, 3g of calcium carbonate, and 2g of magnesium oxide; 0.5g of silane coupling agent KH-570 is used.

[0053] Preparation parameter settings: drying temperature 100°C, time 4h; high-speed mixing temperature 90°C, rotation speed 1000r / min, mixing time 4min and 5min respectively.

[0054] The prepared pellets of a flame-retardant polystyrene composition, the sample obtained by injection molding passed the UL-94 standard test, the flame-retardant effect can reach V-1 level, and the oxygen index is 26%. l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Expansion multiple | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com