Method for preparing CIGS (copper indium gallium selenide) film through selenylation at low temperature

A technology of selenization and thin film, applied in the direction of final product manufacturing, sustainable manufacturing/processing, ion implantation plating, etc., can solve the problems of difficult removal of surfactants, high toxicity, flammability and explosion, etc., and achieve selenization effect Good, eliminate grain boundaries, low toxicity and safe selenization temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] 1. In the preparation method of the present invention, the ratio of copper, indium, gallium, and selenium elements can be adjusted to obtain CIGS nanocrystals with adjustable band gap, and the multi-layer film can be coated on the substrate, so that the finally prepared CIGS thin film can become a gradient distribution. Composite CIGS thin film, thereby greatly improving the efficiency of CIGS thin film solar cells;

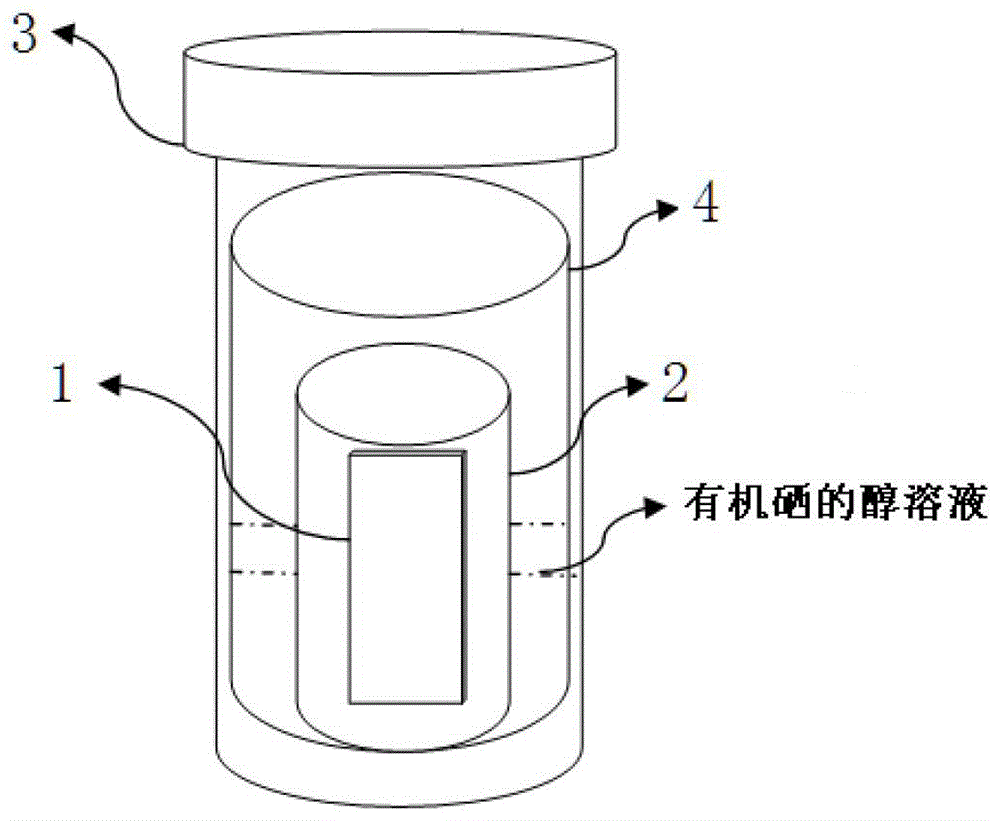

[0053] 2. In the prior art, the selenization of the solid selenium source requires a higher temperature to evaporate the selenium source into steam for selenization. However, the low-temperature selenization of the present invention is carried out at a low temperature of 100-400°C, which is convenient for low tolerance The film is coated on the flexible substrate, and the alcohol solvent will dissolve the residual alkylamine in the CIGS precursor film during the heating process, so as to solve the problem of carbon residue in the CIGS film prepared by the n...

Embodiment 1

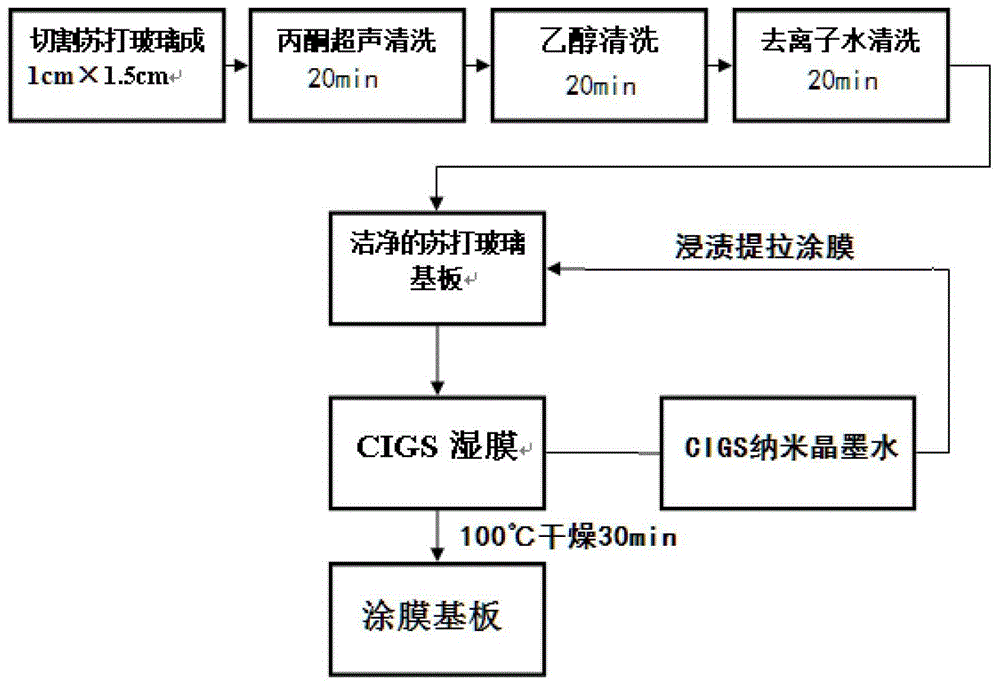

[0057] A method for preparing CIGS film by low-temperature selenization, comprising the steps of:

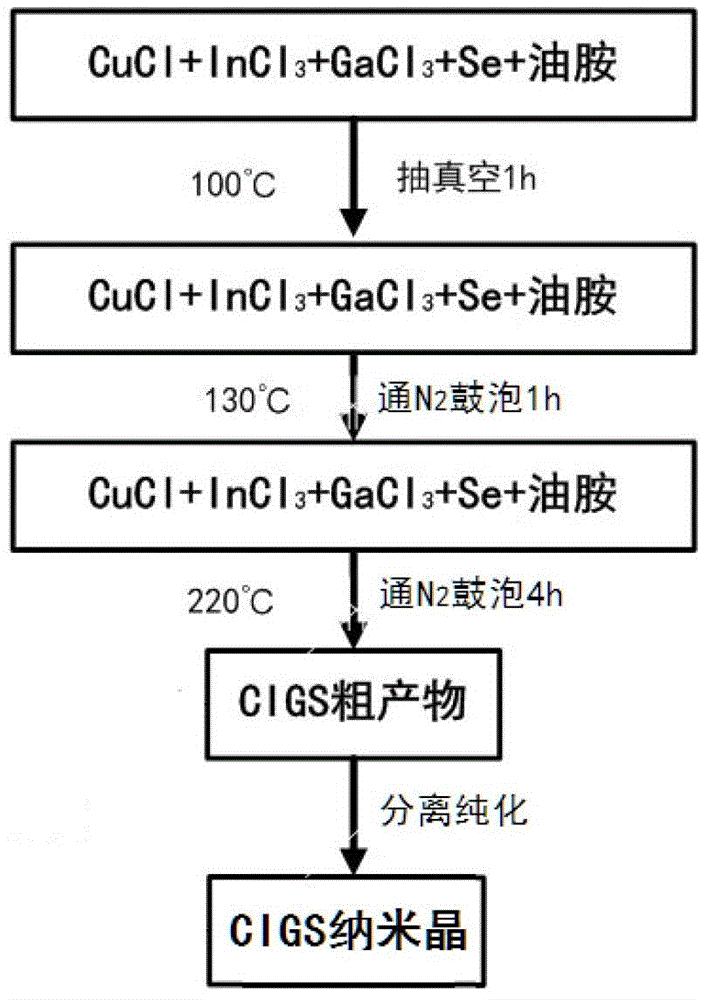

[0058] (1) Preparation of CIGS nanocrystals:

[0059] The preparation process of CIGS nanocrystals is as follows: figure 1 shown in the rich N 2 In the glove box, weigh 10mmol CuCl, 7mmol InCl 3 , 3mmol GaCl 3 and 20mmol Se, mixed and placed in a 250mL three-neck flask with a condenser tube and a stopcock, the flask was removed after closing the stopcock, the stopcock port was immediately connected to the Schlenk tube, and then the flask was wrapped with quartz wool and placed in a heating mantle. Inject another 100ml of oleylamine, open the piston and heat to 100°C, vacuumize at -0.1MPa vacuum for 1h, and then2 Heat to 130°C with magnetic stirring for 1 hour under bubbling, remove water and oxygen, heat up to 220°C and stir vigorously for 4 hours, remove the heating mantle, cool to room temperature to obtain a suspension, separate and purify to obtain CIGS nanocrystals;

[...

Embodiment 2

[0068] A method for preparing CIGS film by low-temperature selenization, comprising the steps of:

[0069] (1) Preparation of CIGS nanocrystals:

[0070] Reference for the preparation process of CIGS nanocrystals figure 1 , in rich N 2 In a glove box, weigh 2mmol copper acetylacetonate, 0.18mmol indium acetylacetonate, 0.2mmol gallium acetylacetonate and 4mmolSe, mix them and place them in a 100mL three-necked flask with a condenser tube and a stopcock, remove the flask after closing the stopcock, and immediately remove the stopcock Connect the mouth of the flask to the Schlenk tube, then wrap the flask with quartz wool and place it in a heating mantle, inject 10ml of octadecylamine, open the piston and heat to 60°C, vacuumize at -0.1MPa for 3h, and then N 2 Heat to 100°C with magnetic stirring for 3 hours under bubbling, remove water and oxygen, heat up to 300°C and vigorously stir for 1 hour, remove the heating mantle, cool to room temperature to obtain a suspension, sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com