Preparation method of flame retardant conductive fiber

A conductive fiber and flame-retardant technology, which is applied in the field of radiation-proof fiber, conductive, and flame-retardant preparation, can solve the problems of not being widely used in the field of personal protection, single function, and inability to ensure the uniform dispersion of stainless steel fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The specific preparation steps of this flame-retardant conductive fiber are as follows:

[0017] (1) Pretreatment: remove impurities on the surface of pre-oxidized fiber raw materials;

[0018] (2) Conductive treatment: Soak the pretreated pre-oxidized fiber in the conductive liquid, raise the temperature to 90°C, and soak for 2 hours until the fiber is black and bright, and the color is uniform; the composition of the conductive liquid is: sulfuric acid pentahydrate Copper 100g / L, sodium thiosulfate 150g / L, scandium 0.3g / L, yttrium 0.5g / L, the solvent of the conductive liquid is distilled water; soak 10g of fiber per liter of conductive liquid;

[0019] (3) Post-treatment: After soaking the fiber in the conductive liquid, the fiber is cleaned, dried, loosened and packaged.

Embodiment 2

[0021] The specific preparation steps of this flame-retardant conductive fiber are as follows:

[0022] (1) Pretreatment: remove impurities on the surface of the original acrylic fiber;

[0023] (2) Conductive treatment: Soak the pretreated acrylic fiber in conductive liquid, raise the temperature to 100°C, soak for 1 hour, until the fiber color is black and bright, and the chroma is uniform; the composition of the conductive liquid is: pentahydrate Copper sulfate 150g / L, sodium thiosulfate 200g / L, scandium 0.5g / L, yttrium 0.5g / L, the solvent of the conductive liquid is distilled water; soak 30g of fiber per liter of conductive liquid;

[0024] (3) Post-treatment: After soaking the fiber in the conductive liquid, the fiber is cleaned, dried, loosened and packaged.

Embodiment 3

[0026] The specific preparation steps of this flame-retardant conductive fiber are as follows:

[0027] (1) Pretreatment: remove impurities on the surface of pre-oxidized fiber raw materials;

[0028] (2) Conductive treatment: Soak the pre-treated pre-oxidized fiber in a conductive liquid, raise the temperature to 100°C, and soak for 1 hour until the fiber color is black and bright, and the chroma is uniform; the composition of the conductive liquid is: sulfuric acid pentahydrate Copper 100~200g / L, sodium thiosulfate 250g / L, scandium 0.5g / L, yttrium 0.7g / L, the solvent of the conductive liquid is distilled water; soak 50g of fiber per liter of conductive liquid;

[0029] (3) Post-treatment: After soaking the fiber in the conductive liquid, the fiber is cleaned, dried, loosened and packaged.

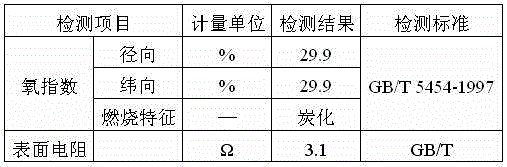

[0030] The physical and chemical properties of the modified preoxidized fiber prepared in Example 1 were tested, and the product properties are shown in Table 1.

[0031] Table 1

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com