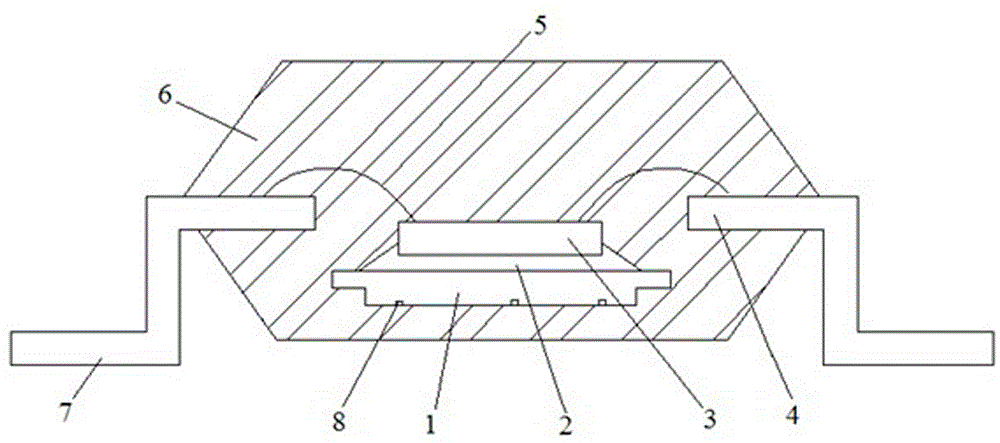

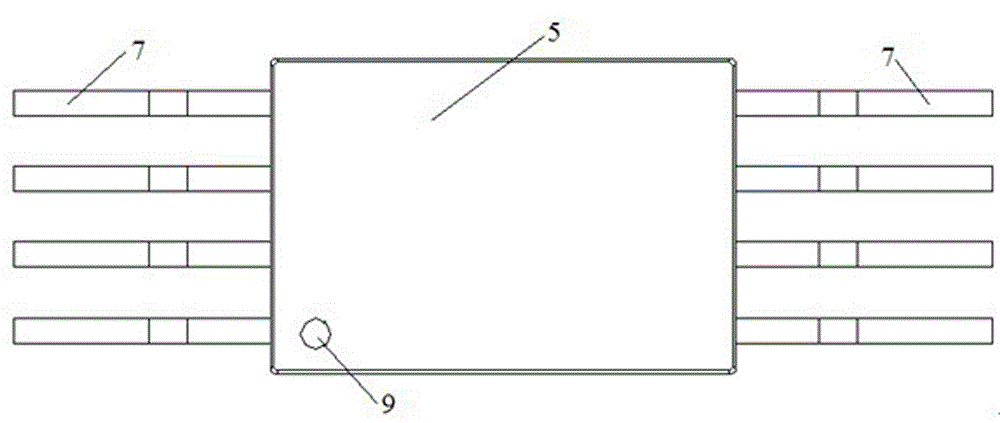

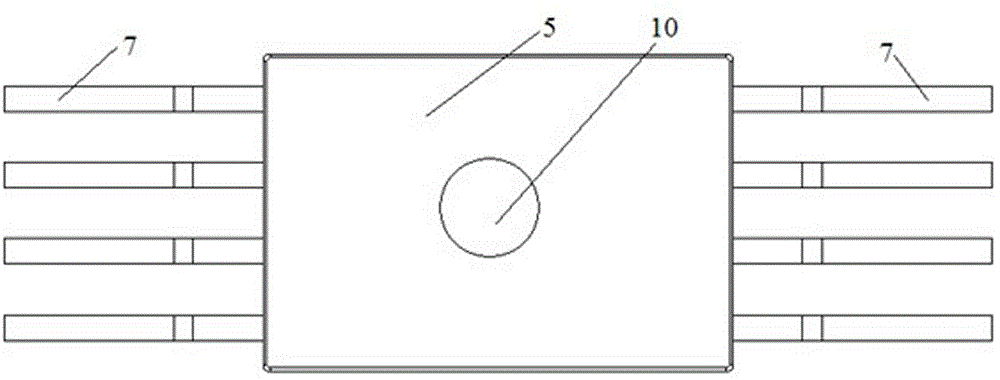

Ultrathin VSOP (very thin small outline package) packaging part and production method thereof

A production method and ultra-thin technology, applied in the direction of electrical components, semiconductor devices, electric solid devices, etc., can solve the problems of low packaging yield and high cost of small lead-out wire packaging, and achieve the effect of preventing product deviation and avoiding suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Through rough grinding, fine grinding and polishing, a wafer with a final thickness of 150 μm is obtained; during rough grinding, the rough grinding speed is 100 μm / min, and the rough grinding thickness ranges from the original wafer thickness + film thickness to 200 μm + film thickness; When grinding, the accuracy speed is 9μm / min, and the precision thickness ranges from 200μm + film thickness to 160μm + film thickness; when polishing, mechanical polishing is performed first, and then chemical polishing; polishing thickness ranges from 160μm + film thickness to 150μm + film thickness Thickness, the process of preventing chip warpage is adopted in the process of wafer thinning. Use DISC 3350 dicing machine to dicing the thinned wafers, set anti-fragmentation and anti-crack scribing optimization parameters through DOE optimization, scribing feed speed 6mm / s, clean and dry in time after scribing; take Stamped multi-row copper alloy electroplating lead frame with anti-spla...

Embodiment 2

[0079] Through rough grinding, fine grinding and polishing, a wafer with a final thickness of 170 μm is obtained; during rough grinding, the rough grinding speed is 75 μm / min, and the rough grinding thickness ranges from the original wafer thickness + film thickness to 220 μm + film thickness; When grinding, the accuracy speed is 10μm / min, and the precision thickness ranges from 220μm + film thickness to 180μm + film thickness; when polishing, mechanical polishing is performed first, and then chemical polishing; polishing thickness ranges from 180μm + film thickness to 170μm + film thickness Thickness, the process of preventing chip warpage is adopted in the process of wafer thinning. Use DISC 3350 dicing machine to dicing the thinned wafers, set anti-fragmentation and anti-crack scribing optimization parameters through DOE optimization, scribing feed speed 10mm / s, clean and dry in time after scribing; take Stamped multi-row nickel-palladium-gold electroplated lead frame with ...

Embodiment 3

[0081] Through rough grinding, fine grinding and polishing, a wafer with a final thickness of 160 μm is obtained; during rough grinding, the rough grinding speed is 50 μm / min, and the rough grinding thickness ranges from the original wafer thickness + film thickness to 210 μm + film thickness; When grinding, the accuracy speed is 8μm / min, and the accuracy thickness ranges from 210μm + film thickness to 170μm + film thickness; when polishing, mechanical polishing is performed first, and then chemical polishing; polishing thickness ranges from 170μm + film thickness to 160μm + film thickness Thickness, the process of preventing chip warpage is adopted in the process of wafer thinning. Use DISC 3350 dicing machine to dicing the thinned wafers, set anti-fragmentation and anti-crack scribing optimization parameters through DOE optimization, scribing feed speed 8mm / s, clean and dry in time after scribing; take Stamped multi-row silver-plated lead frame with anti-spill film attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com