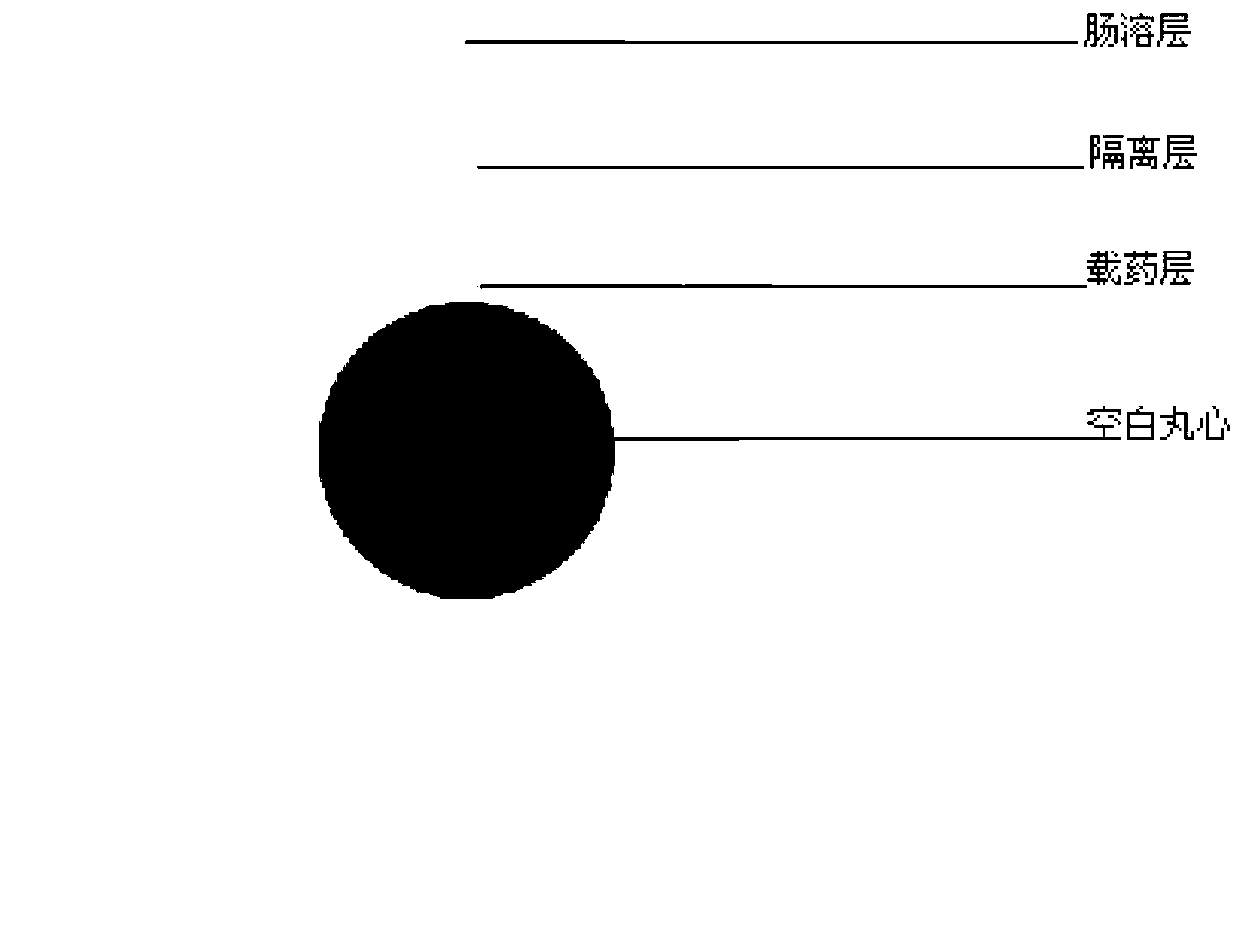

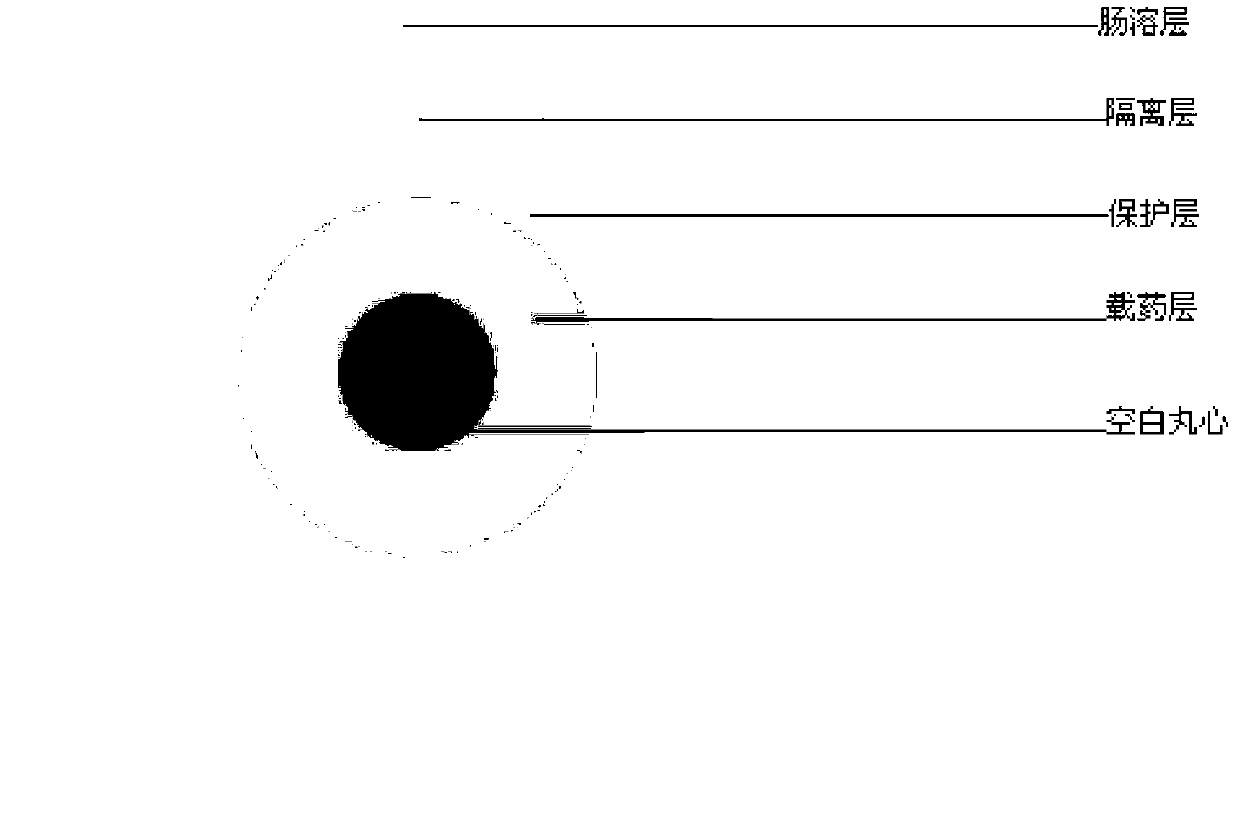

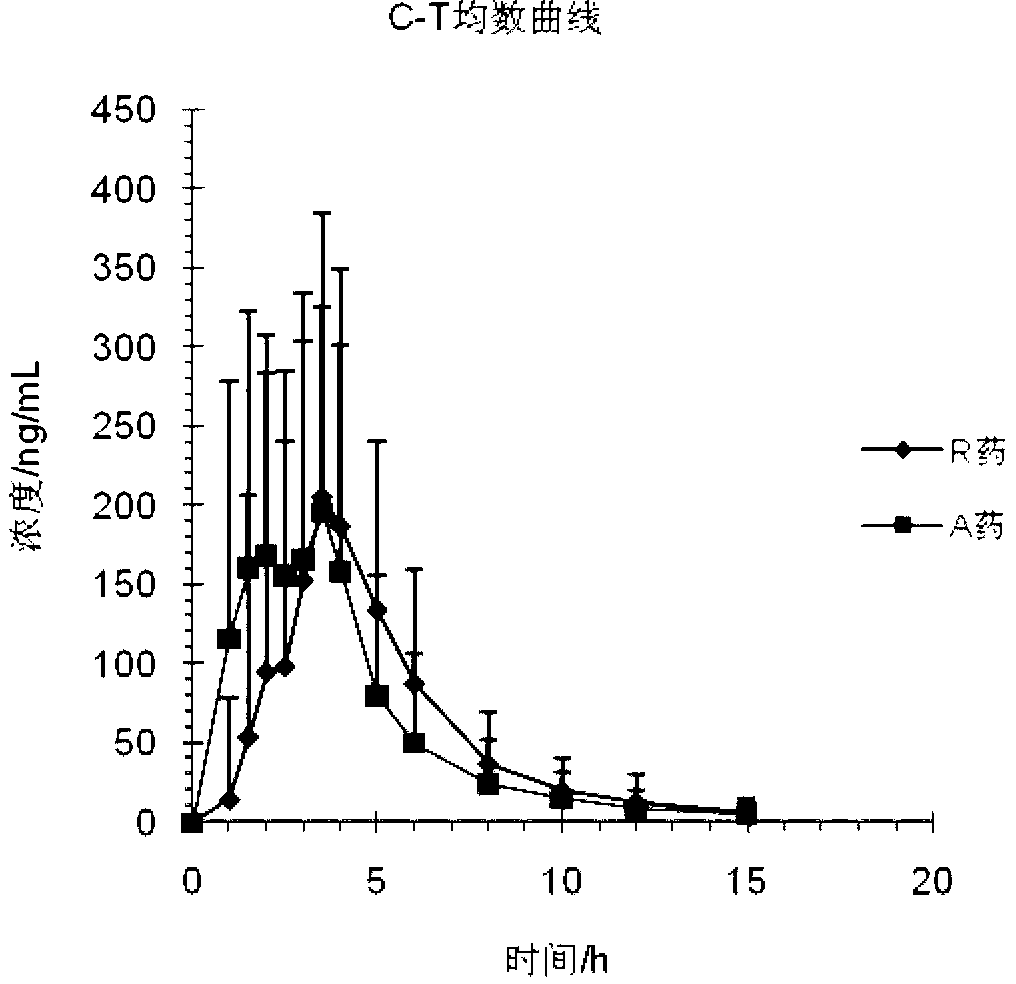

Enteric coating pellet of proton pump inhibitor

An enteric-coated pellet and proton pump technology, which is used in the delivery of pills, medical preparations containing active ingredients, and the digestive system, can solve the problems of low in vitro release and rise of related substances, and achieves improved in vitro release and improved The effect of stability, good business prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The processing of embodiment 1 calcium carbonate micronization

[0028] Take by weighing 50Kg of calcium carbonate coarse powder of 80 mesh sieves, put gas into MQL03 jet mill (manufactured by Weifang Erpai Powder Technology Equipment Co., Ltd.) for micronization, and pass through a 325-mesh sieve to obtain micronized calcium carbonate 42.3 Kg, the yield is 84.6%. Get the micronized calcium carbonate sample and detect it with a Mastersizer2000 Malvern laser particle size analyzer (manufactured by Malvern Instruments, UK), and the D90 is 30.7um.

Embodiment 2

[0029] The processing of embodiment 2 magnesium carbonate micronization

[0030] Take by weighing 50Kg of magnesium carbonate coarse powder of 80 mesh sieves, put it in an MQL03 jet mill (manufactured by Weifang Erpai Powder Technology Equipment Co., Ltd.) for micronization, and pass through a 300 mesh sieve to obtain micronized magnesium carbonate 42.3 Kg, the yield is 84.6%. Get the micronized magnesium carbonate sample, and detect it with a Mastersizer2000 Malvern laser particle size analyzer (manufactured by Malvern Instruments, UK), and the D90 is 45.2um.

Embodiment 3

[0031] The processing of embodiment 3 calcium hydroxide micronization

[0032]Weigh 50Kg of calcium hydrochloride coarse powder through a 80-mesh sieve, put it into an MQL03 jet mill (manufactured by Weifang Erpai Powder Technology Equipment Co., Ltd.) for micronization, and pass through a 200-mesh sieve to obtain micronized hydrogen Calcium oxide 45.9Kg, yield is 91.8%. Take the micronized calcium hydroxide sample and detect it with a Mastersizer 2000 Malvern laser particle size analyzer (manufactured by Malvern Instruments, UK), and the D90 is 68.7um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| linear range | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com