Method for removing sodium oxalate from sodium aluminate solution through lime causticization

A technology of sodium oxalate and sodium aluminate, which is applied in the field of metallurgy, can solve the problems of large amount of lime addition, difficulty in sedimentation and separation, and large loss of alumina, so as to reduce the amount of lime addition, increase the causticization rate, and suppress back-causticization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

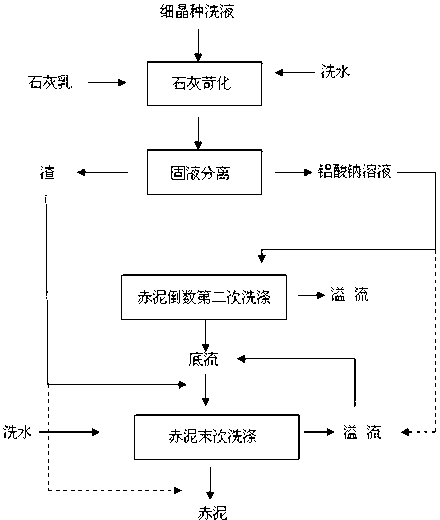

Image

Examples

Embodiment 1

[0015] Dilute the aluminum hydroxide fine seed lotion with red mud washing water, and control the composition of the diluted solution to: Na 2 O T 15g / L, Na 2 O k 15g / L, Al 2 O 3 8.2g / L, Na 2 C 2 O 4 10g / L, according to CaO / Na 2 C 2 O 4 With a molecular ratio of 1, add lime with a particle size of less than 0.9mm, control the stirring speed to 900rpm, and react at 50°C for 1h. The slurry obtained by the reaction is sedimented and separated to obtain a sodium aluminate solution after sodium oxalate. The removal rate of sodium oxalate in sodium aluminate solution is 80.45%, and the sodium aluminate solution after sodium oxalate removal 2 C 2 O 4 The concentration is 0.95g / L. Put the underflow obtained after sedimentation and separation in Na 2 O k 10g / L, Al 2 O 3 11g / L, stirring for 2h at 95℃, decausticizing rate of calcium oxalate is 2.1%, Na in solution 2 C 2 O 4 The concentration is 0.13g / L.

Embodiment 2

[0017] Dilute the aluminum hydroxide fine seed lotion with red mud washing water, and control the composition of the diluted solution to: Na 2 O T 10g / L, Na 2 O k 8g / L, Al 2 O 3 4.1g / L, Na 2 C 2 O 4 8g / L, according to CaO / Na 2 C 2 O 4 The molecular ratio is 0.6 and fresh lime milk is added. The solid particle size in the lime milk is less than 0.9mm. The stirring speed is controlled to 900 rpm, and the reaction is performed at 30°C for 1 hour. The slurry obtained from the reaction was separated by sedimentation to obtain an overflow of the sodium aluminate solution after sodium oxalate, and the solid content in the overflow was 0.1 g / L. The removal rate of sodium oxalate in sodium aluminate solution is 60.78%, and the sodium aluminate solution after sodium oxalate removal 2 C 2 O 4 The concentration is 3.92g / L. Put the underflow obtained after solid-liquid separation in Na 2 O k 3g / L, Al 2 O 3 3.2g / L, stirring at 95℃ for 2h, the decausticizing rate of calcium oxalate is 0....

Embodiment 3

[0019] Dilute the aluminum hydroxide fine seed lotion with red mud washing water, and control the composition of the diluted solution to: Na 2 O T 25g / L Na 2 O k 20g / L, Al 2 O 3 11.1 / L, Na 2 C 2 O 4 15g / L, according to CaO / Na 2 C 2 O 4 With a molecular ratio of 2, add lime with a particle size of less than 0.15mm, control the stirring speed to 1000rpm, and react at 70°C for 10min. The slurry obtained by the reaction is sedimented and separated to obtain a sodium aluminate solution after sodium oxalate. The removal rate of sodium oxalate in sodium aluminate solution is 90.34%, and the sodium aluminate solution after sodium oxalate removal 2 C 2 O 4 The concentration is 1.45g / L. Place the wet cake obtained after solid-liquid separation in Na 2 O k 3g / L, Al 2 O 3 3.2g / L, stirring at 95℃ for 2h, the decausticizing rate of calcium oxalate is 0.24%, Na in solution 2 C 2 O 4 The concentration is 0.10g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com