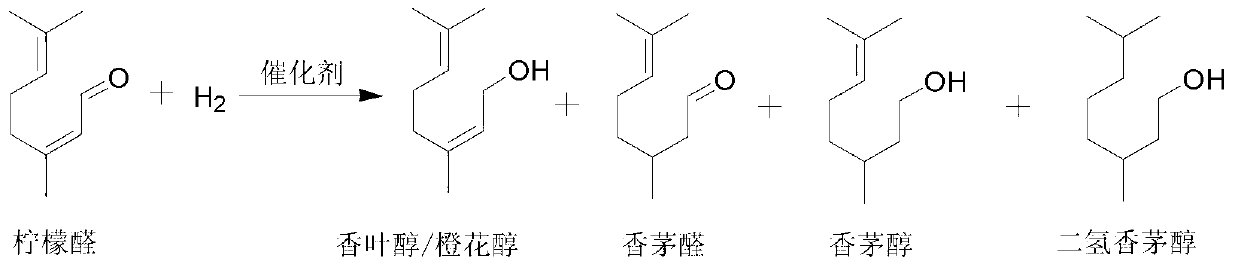

Method for selective hydrogenation synthesis of nerol and geraniol mixture by using citral in water-organic two-phase system

A citral and selective technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve problems such as harsh operating conditions, achieve convenient post-processing, simple process, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 10g of ruthenium acetate and tris-(p-phenoxy-polyoxyethylene ether)-phosphine complex catalyst (mass ratio of ruthenium acetate to tri-(p-phenoxy-polyoxyethylene ether)-phosphine is 0.008:1), Add 500g of water into a 2L autoclave with magnetic stirring and a temperature controller, then add 500g of citral, replace with nitrogen three times, then replace with hydrogen three times, heat to 100°C, pressurize hydrogen to 0.5MPa, stir at 500rpm, Reacted for 2 hours, and the conversion rate of sampling analysis of citral was greater than 98%. Cool with water, press out the reaction solution, leave to stand for stratification, the water phase is the catalyst and can be applied to the next batch of reactions, and the organic phase is a mixture of geraniol and nerol. According to gas chromatography analysis, the conversion rate of citral was 98.85%, and the total selectivity of nerol / geraniol was 99.10%.

Embodiment 2

[0024] Add 20g of rhodium nitrate and sodium triphenylphosphine sulfonate complex catalyst (mass ratio of rhodium nitrate to sodium triphenylphosphine sulfonate is 0.001:1), 1000g of water into a 2L autoclave with magnetic stirring and temperature controller Then add 100g of citral, replace it with nitrogen three times, then replace it with hydrogen three times, heat to 150°C, pressurize the hydrogen to 1.5MPa, stir at 1000rpm, react for 20 hours, take samples and analyze the conversion rate of citral is greater than 98%. Cool with water, press out the reaction solution, leave to stand for stratification, the water phase is the catalyst and can be applied to the next batch of reactions, and the organic phase is a mixture of geraniol and nerol. According to gas chromatography analysis, the conversion rate of citral was 98.68%, and the total selectivity of nerol / geraniol was 99.22%.

Embodiment 3

[0026] With 25g palladium chloride and three-(4-methoxy group-3-sodium sulfonate phenyl)phosphine complex catalyst (palladium chloride and tri-(4-methoxy group-3-sulfonate sodium phenyl)phosphine The mass ratio is 0.01:1), 800g of water was added into a 2L autoclave with magnetic stirring and a temperature controller, and then 200g of citral was added, replaced with nitrogen three times, and then replaced with hydrogen three times, heated to 30°C, and added with hydrogen Pressed to 1.4MPa, stirred at 800rpm, reacted for 12 hours, and the conversion rate of citral was greater than 98% by sampling analysis. Squeeze out the reaction liquid, let it stand for stratification, the water phase is the catalyst and can be applied to the next batch of reactions, and the organic phase is the mixture of geraniol and nerol. According to gas chromatography analysis, the conversion rate of citral was 98.23%, and the total selectivity of nerol / geraniol was 99.52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com