High-surface-gloss environment-friendly halogen-free flame-retardant PBT (polybutylene terephthalate) composite material and preparation method thereof

A composite material and environmental protection technology, which is applied in the field of high-gloss surface environmental protection halogen-free flame retardant PBT composite material and its preparation, which can solve the problems of inability to form high-end products, affecting the apparent performance of products, and existing appearance, and meeting strong market demand. , excellent processability, good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

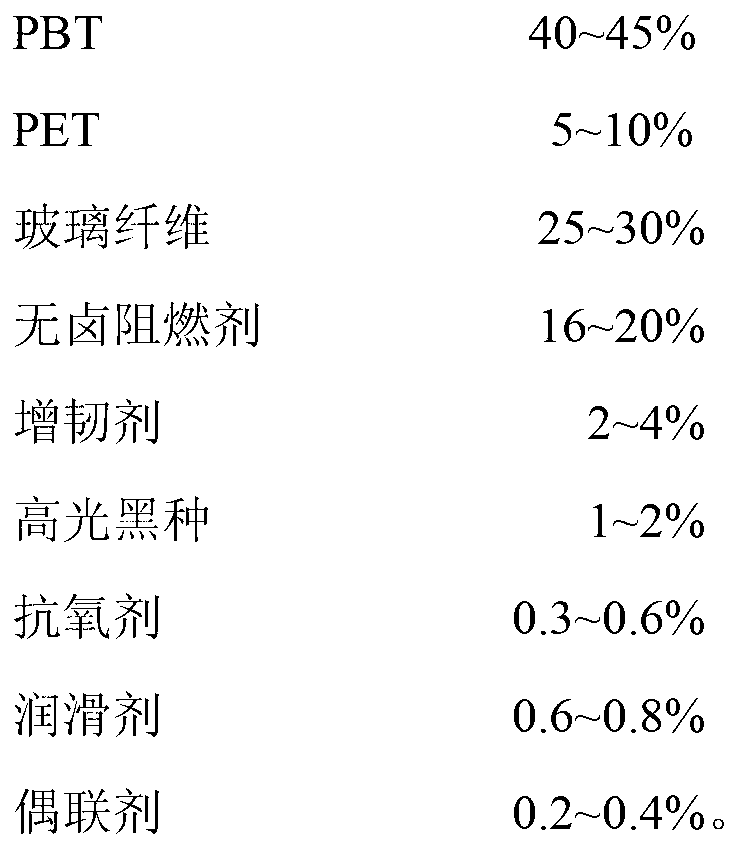

[0039] A high-gloss surface environmentally friendly halogen-free flame-retardant PBT composite material, its formula composition is shown in Table 1:

[0040] Table 1 Composite material formula

[0041] raw material parts by mass PBT (Nantong PBT1100, viscosity is 1.0) 9 PBT (Nantong PBT1084, viscosity is 0.84) 34.5 PET (Yizheng PETSB500, viscosity 0.6~0.7) 8 Alkali-free long glass fiber filament (Taishan glass fiber) 26 Aluminum hypophosphite 14 Triphenyl Phosphate 2 Ethylene-methyl methacrylate copolymer 3 Carrier-free inorganic black species 2 Antioxidant 1100 0.6 Lubricant PETS 0.6 γ-Glycidyl etheroxypropyl trimethoxysilane 0.3

Embodiment 2

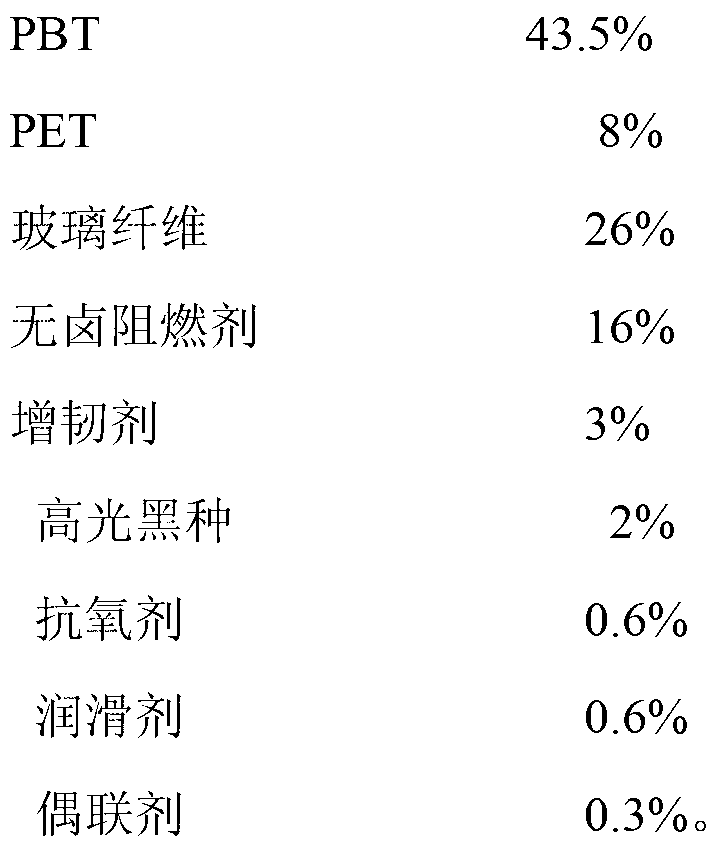

[0043] A high-gloss surface environmentally friendly halogen-free flame-retardant PBT composite material, the formula composition of which is shown in Table 2:

[0044] Table 2 Composite material formula

[0045] raw material parts by mass PBT (Nantong PBT1100, viscosity is 1.0) 23.5 PBT (Nantong PBT1084, viscosity is 0.84) 20 PET (Yizheng PETSB500, viscosity 0.6~0.7) 8 Alkali-free long glass fiber filament (Taishan glass fiber) 26 Aluminum hypophosphite 14 Triphenyl Phosphate 2 Ethylene-methyl methacrylate copolymer 3 Carrier-free inorganic black species 2 Antioxidant 1100 0.6 Lubricant PETS 0.6 γ-Glycidyl etheroxypropyl trimethoxysilane 0.3

Embodiment 3

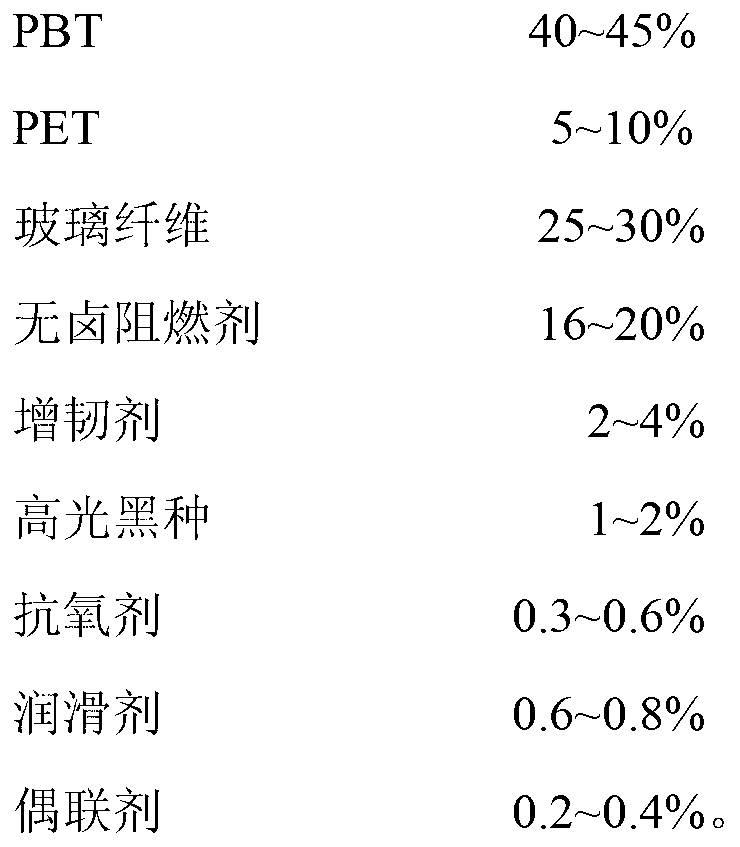

[0047] A high-gloss surface environmentally friendly halogen-free flame-retardant PBT composite material, the formula composition of which is shown in Table 3:

[0048] Table 3 Composite material formula

[0049] raw material parts by mass PBT (Nantong PBT1100, viscosity is 1.0) 9 PBT (Nantong PBT1084, viscosity is 0.84) 39.5 PET (Yizheng PETSB500, viscosity 0.6~0.7) 3 Alkali-free long glass fiber filament (Taishan glass fiber) 26 Aluminum hypophosphite 14 Triphenyl Phosphate 2 Ethylene-methyl methacrylate copolymer 3 Carrier-free inorganic black species 2 Antioxidant 1100 0.6 Lubricant PETS 0.6 γ-Glycidyl etheroxypropyl trimethoxysilane 0.3

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com