Magnetic microbial carrier and preparation method thereof

A technology of magnetic microorganisms and carriers, which is applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problems that microorganisms and carriers are difficult to form a diverse environment, and porous carriers cannot be effectively fixed. , to achieve rich cell structure, promote nitrification and denitrification effect, and high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention also relates to a method for preparing the above-mentioned magnetic microbial carrier, the steps of the preparation method are as follows:

[0053] Step 10, put starch and polyvinyl alcohol aqueous solution in a water bath at 90°C, mechanically stir until dissolved, then add ethylene glycol and sulfuric acid as an acid catalyst;

[0054] Step 20. Stir the above solution evenly at 55-75°C, slowly add formaldehyde, and add composite reinforcement components, and at the same time rapidly increase the stirring speed, control the reaction time for 20 minutes, then add silicon-coated magnetic powder, and stir for 10 minutes to form a foam solution;

[0055] Step 30: Pour the foam liquid into the mold and react at 55-75°C for about 18-22 hours to obtain the magnetic microbial carrier formed by polycondensation reaction of polyvinyl alcohol and formaldehyde.

[0056] The preparation method of the silicon-coated magnetic powder is as follows: disperse the f...

Embodiment 1

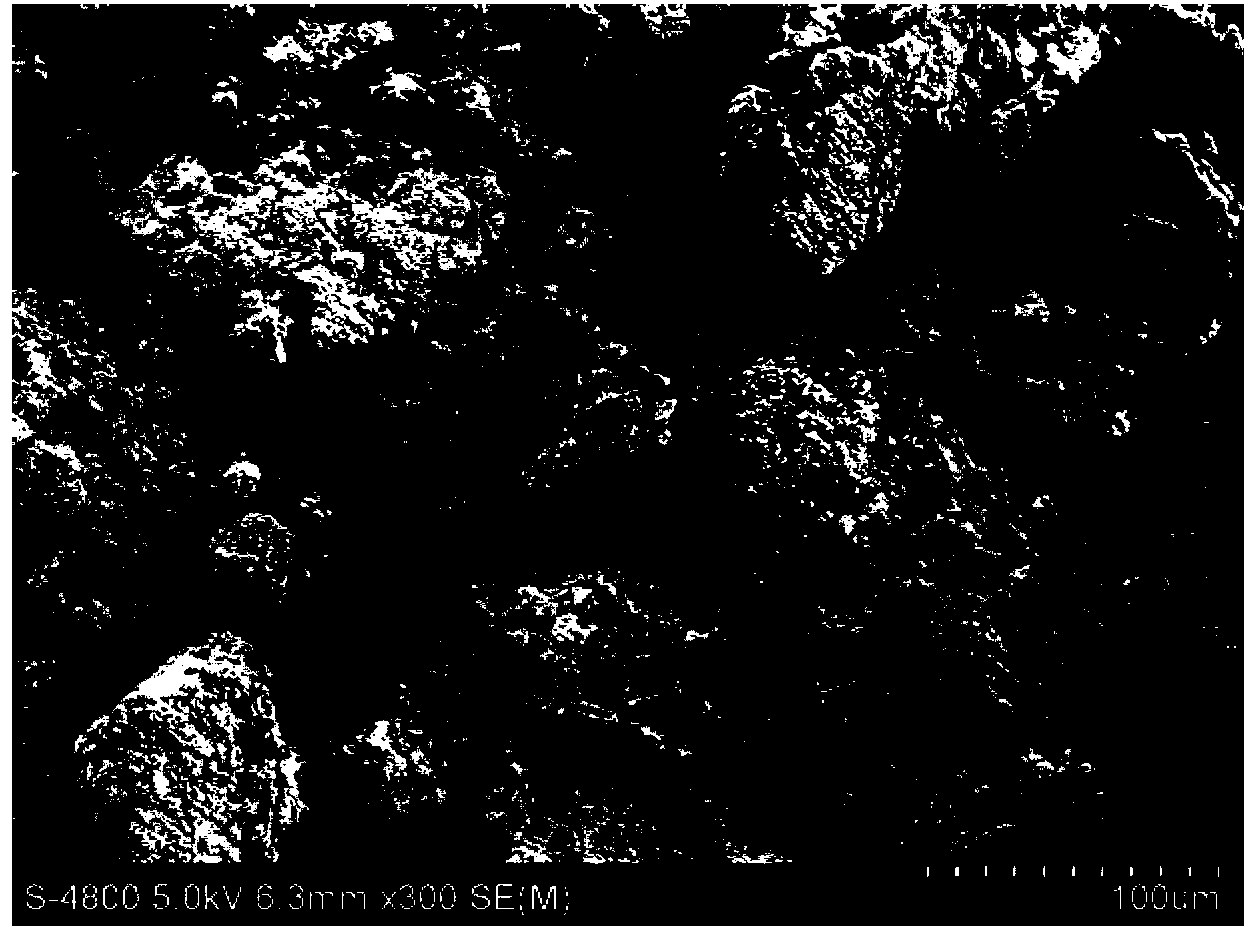

[0062] The synthesis of the carrier is through polycondensation reaction. The polycondensation steps are as follows: 20g starch and 200g PVA water bath are heated to 90°C, stirred and dissolved in 2000ml distilled water. After the components are completely dissolved, add 80ml of sulfuric acid (4.7M) and composite reinforcement components. Lower the temperature of the water bath to 65°C and stabilize for 10 minutes, stir and add 80ml of formaldehyde solution (40wt.%), and react at 65°C for 20 minutes, add silicon-coated magnetic powder with a mass fraction of 1.67% to 2.5%, and stir for 10 minutes. The foaming liquid is poured into the molding mold, and reacted and molded in a blast drying oven at 65°C for 20h. The obtained carrier is properly cut (0.002×0.002m×m) to obtain the finished product. The state of the surface of the magnetic microbial carrier under the electron microscope is as follows: figure 1 shown.

[0063] The preparation method of silicon-coated magnetic powd...

Embodiment 2

[0065] Check the effect of sewage treatment:

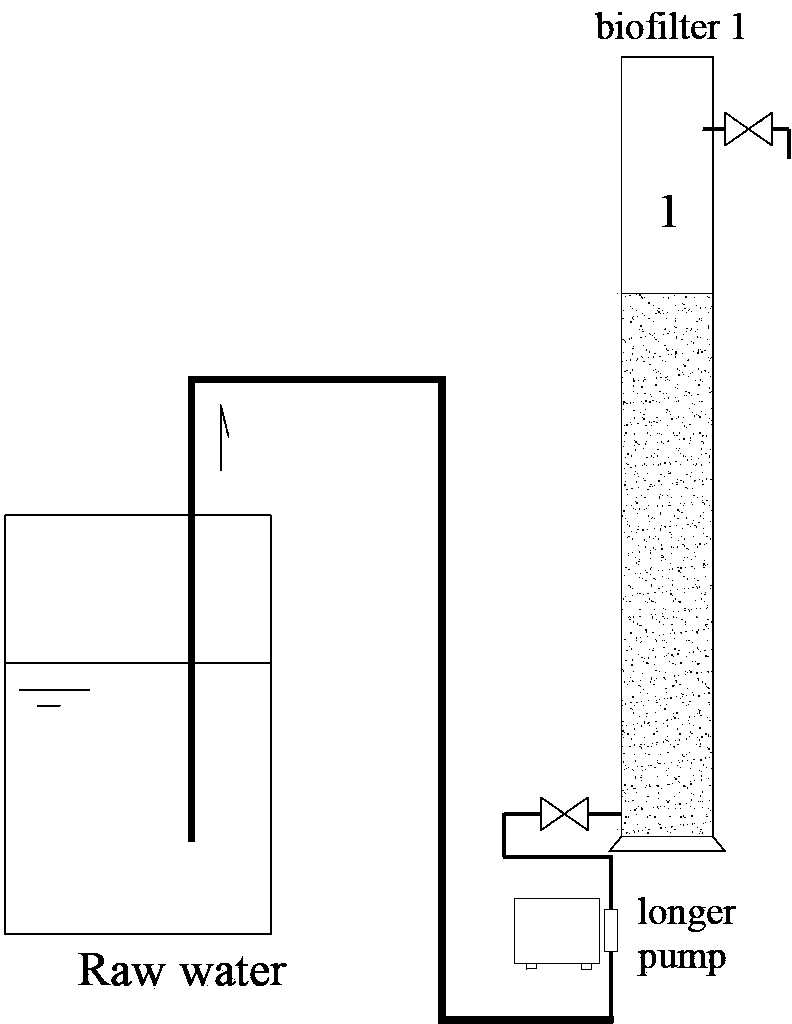

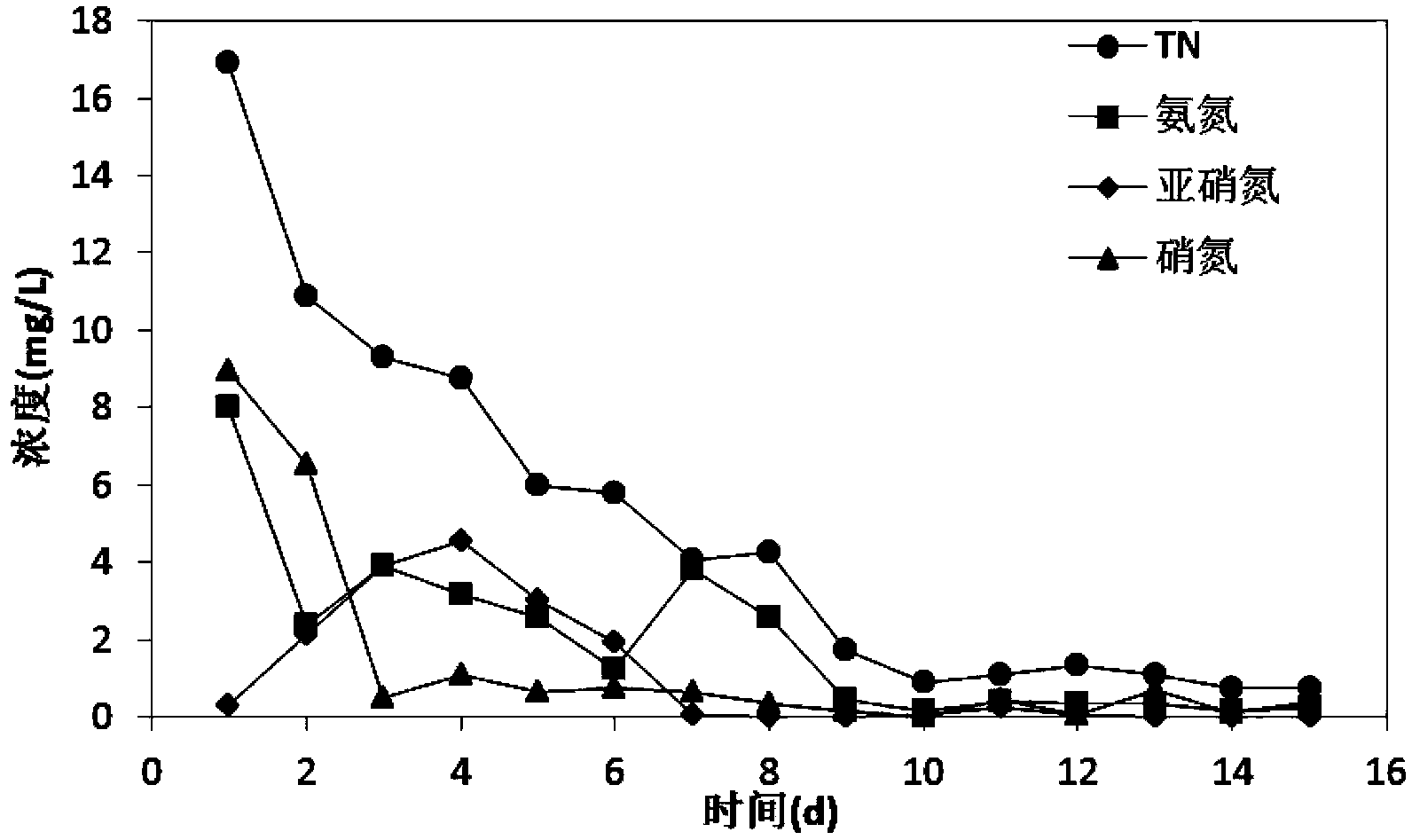

[0066] A filter column was designed to explore the effect of the carrier on the treatment of mariculture wastewater. The filter column has a bottom diameter of 2×10 -3 m polystyrene pipe, the filling height of the filter material is 0.228m, and the top has a super height of 0.1m, such as figure 2 shown. Simulated sewage components, COD Mn The concentration is 108-165mg·L -1 , TN concentration 13.9-14.8mg·L -1, NH 4 + -N concentration 4.7-5.1mg·L -1 , NO3 - -N concentration 9.3-9.5mg·L -1 , with a salinity of 35g·L -1 . The concentration in 20ml is 5167mg·L -1 The activated sludge is added to the filter column as a hanging film. Monitor the concentration of total nitrogen, ammonia nitrogen, nitrate nitrogen, and nitrite nitrogen in the effluent of the filter column, and analyze the pollutant removal effect under the influence of different carriers.

[0067] The filter column effluent concentration of above-mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com