Anti-fouling and corrosion-resistant coating composition and application thereof on ships or structures in water

A technology of anti-corrosion coatings and compositions, applied in anti-corrosion coatings, anti-fouling/underwater coatings, polyamide coatings, etc., can solve problems such as poor adhesion and durability, and achieve good durability and anti-fouling corrosion Protective performance, the effect of excellent corrosion protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

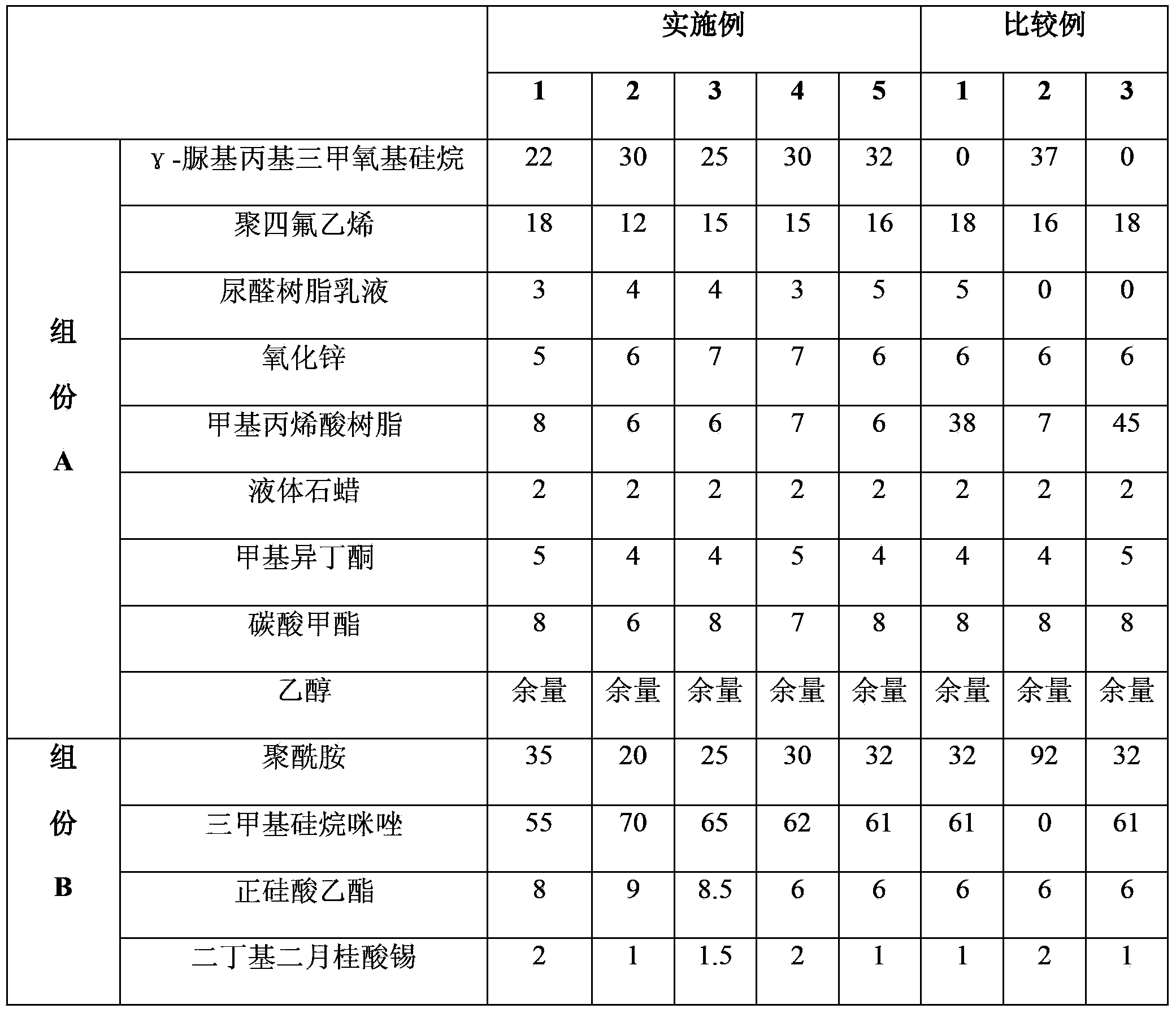

[0019] An antifouling and anticorrosion coating composition is composed of component A and component B, wherein the mass ratio of component A and component B is 5:1; wherein, component A is composed of 22wt% gamma-ureidopropyl Trimethoxysilane, 18wt% polytetrafluoroethylene, 3wt% urea-formaldehyde resin emulsion, 5wt% zinc oxide, 8wt% methacrylic resin, 2wt% liquid paraffin, 5wt% methyl isobutyl ketone, 8wt% methyl carbonate and the rest of ethanol; component B consists of 35wt% polyamide, 55wt% N-trimethylsilylimidazole, 8wt% ethyl orthosilicate and 2wt% dibutyl dilaurate Acid tin composition.

[0020] The preparation method of described coating is as follows:

[0021] (1) Grind PTFE, urea-formaldehyde resin emulsion, zinc oxide, methacrylic resin, methyl isobutyl ketone, methyl carbonate and ethanol in a ball mill for 0.5-1h; (2) Grind liquid paraffin and urea The silane is mixed evenly; (3) Mix the materials in step (1) and step (2) fully to obtain component A; (4) Polyam...

Embodiment 2-5 and comparative example 1-3

[0023] According to the composition and proportion in Table 1, the same operation as in Example 1 was carried out to obtain the antifouling and anticorrosion coating films described in Examples 2-5 and Comparative Examples 1-3.

[0024] Evaluation method

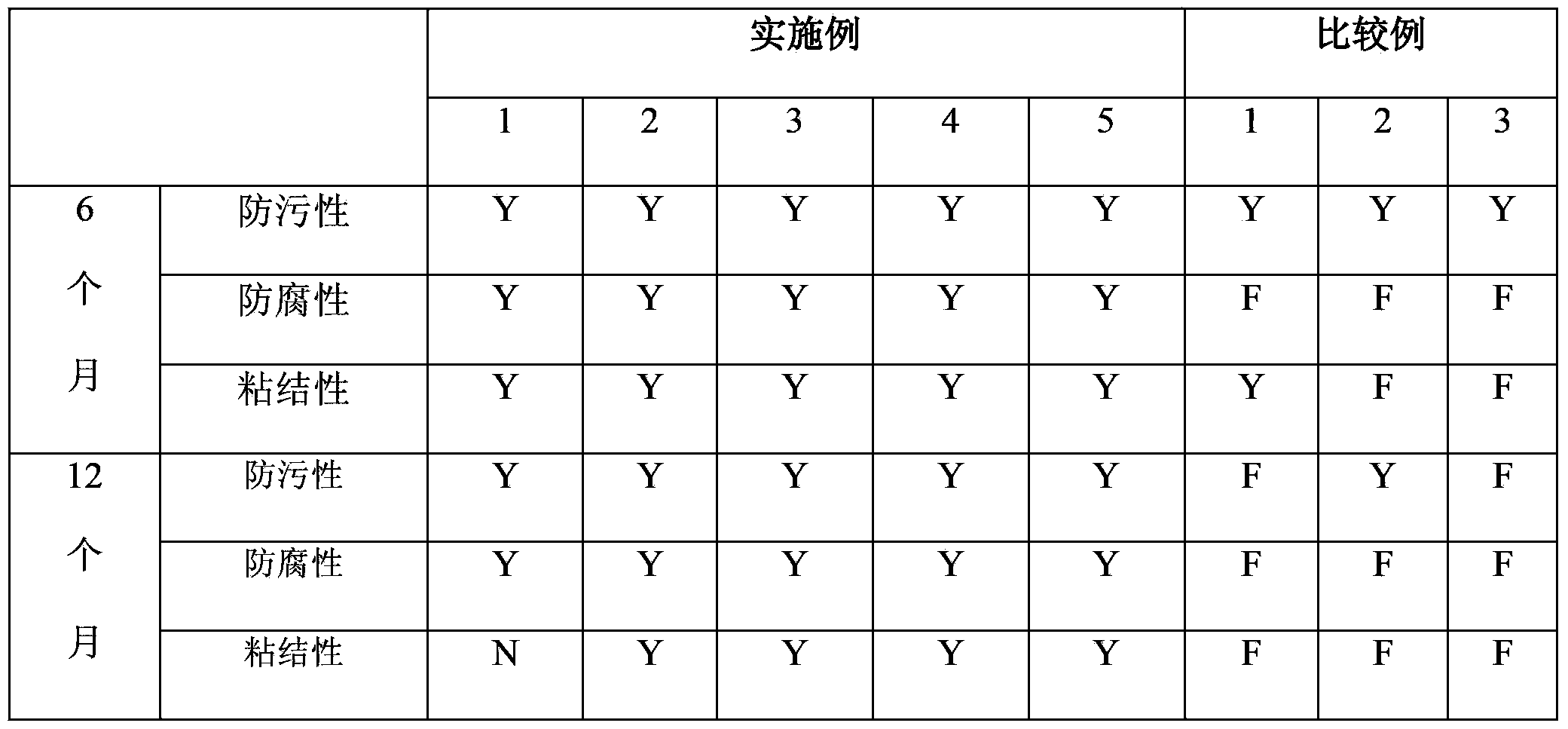

[0025] The steel plate with anti-fouling and anti-corrosion coating formed by Examples 1-5 and Comparative Examples 1-3 is placed in a bamboo cage, immersed in seawater with a water depth of 1m, placed for 6 months and 12 months, and evaluated. Stain resistance, corrosion resistance and adhesion. The evaluation results are shown in Table 2.

[0026] Antifouling

[0027] Check with the naked eye for visible marine organisms. Y: no attachment, F: attachment.

[0028] Corrosion resistance

[0029] Visually observe whether there are blisters on the surface of the steel plate with anti-fouling and anti-corrosion coating after immersion for 6 months and 12 months.

[0030] Y: No abnormality, F: Blistering occurred.

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com