Preparation method of castor-oil-coated zinc oxide nano particle

A nano-zinc oxide and castor oil technology, applied in the field of nano-materials, achieves the effects of less environmental pollution, easy-to-obtain raw materials, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

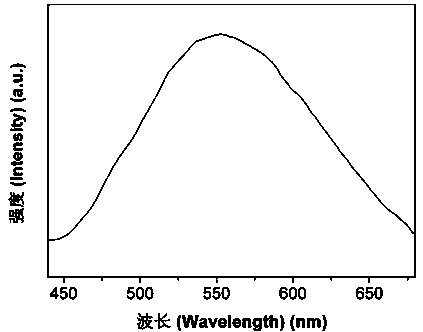

Image

Examples

Embodiment 1

[0022] (1) 0.22 g of zinc acetate was added to 3.95 g of ethanol, stirred for 20 minutes to fully dissolve it, and an ethanol solution containing zinc salt was obtained.

[0023] (2) add the castor oil of 28.65 grams in the ethanol solution that contains zinc salt that step (1) makes, stir 30 minutes, be heated to 80 ℃ of refluxed 120 minutes again, make the castor oil solution that contains zinc salt.

[0024] (3) in the castor oil solution that contains zinc salt that step (2) makes, the amount concentration of adding 2 grams of substances is the sodium hydroxide ethanolic solution of 1 mol / liter, continues to stir 2 hours at 80 ℃, is then cooled to At room temperature, centrifuged, washed with ethanol for 4 times, and then dried at 60° C. for 12 hours to prepare castor oil-coated zinc oxide nanoparticles.

Embodiment 2

[0026] (1) Add 0.068 gram of zinc chloride into 2.37 gram of methanol, stir for 10 minutes to fully dissolve it, and obtain a methanol solution containing zinc salt.

[0027] (2) add the castor oil of 19.1 grams in the methanol solution that contains zinc salt that step (1) makes, stir 60 minutes, be heated to 75 ℃ of refluxed 120 minutes again, make the castor oil solution that contains zinc salt.

[0028] (3) adding 1 gram of substance concentration in the castor oil solution containing zinc salt that step (2) makes is the sodium hydroxide ethanolic solution of 1 mol / liter, continues to stir 1 hour at 120 ℃, is then cooled to At room temperature, centrifuged, washed with ethanol for 3 times, and then dried at 60° C. for 12 hours to prepare castor oil-coated zinc oxide nanoparticles.

Embodiment 3

[0030] (1) 0.225 grams of zinc bromide was added to 8.92 grams of ethylene glycol, and stirred for 30 minutes to fully dissolve it to obtain a zinc salt-containing ethylene glycol solution.

[0031] (2) add the castor oil of 28.65 grams in the ethylene glycol solution that contains zinc salt that step (1) makes, stir 90 minutes, be heated to 90 ℃ of refluxes 30 minutes again, make the castor oil solution that contains zinc salt.

[0032] (3) in the castor oil solution that contains zinc salt that step (2) makes, adding 2 grams of substance concentration is the potassium hydroxide ethanolic solution of 1 mol / liter, continues to stir 0.5 hour at 150 ℃, is then cooled to At room temperature, centrifuged, washed with ethanol for 4 times, and then dried at 60° C. for 12 hours to prepare castor oil-coated zinc oxide nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com