Short-fiber ring dyeing yarn preparation method

A short fiber and yarn technology, which is applied in the field of short fiber ring dyed yarn preparation, can solve the problems of chemical additives and energy consumption, large sewage discharge, insignificant "white core" effect, and difficult control of dyeing conditions, etc. Remarkable effect of ring dyeing, low consumption of dyestuffs, chemical auxiliaries and energy, and wide selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

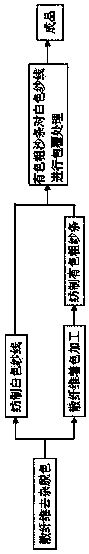

Image

Examples

Embodiment 1

[0019] Spinning a kind of yarn count is the white core ring dyeing yarn that " core layer " and " cortex " of 35s are cotton fiber, specifically comprises the following steps:

[0020] Step a: Purifying and decolorizing the loose fibers: adding 1% of penetrating agent, 8% of hydrogen peroxide, 10% of sodium hydroxide, and CBI 3 of hydrogen peroxide stabilizer in the bulk fiber dyeing machine in sequence %, weight bath ratio 1:10, rise to 95°C at 1.5°C / min, and keep warm for 180min.

[0021] Step b: coloring processing of loose fibers: coloring the cotton fibers treated in step a to remove impurities and decolorize by adopting a conventional dyeing method with reactive dyes;

[0022] Step c: Spinning spun yarns from uncolored fibers: spinning the cotton fibers removed and decolorized in step a into 80s spun yarns;

[0023] Step d: spinning colored roving sliver: spinning the colored cotton fiber processed in step b into roving sliver;

[0024] Step e: Spinning "white core" ri...

Embodiment 2

[0026] Spinning a kind of " core layer " that yarn count is 20s is viscose fiber, and " cortex " is the white core ring dyeing yarn of cotton fiber, specifically comprises the following steps:

[0027] Step a: Removing impurities and decolorizing treatment of loose fibers.

[0028] The cotton fiber treatment process is as follows: in the bulk fiber dyeing machine, 1.5% penetrant, 10% hydrogen peroxide, 12% sodium hydroxide, 4% hydrogen peroxide stabilizer CBI are sequentially added according to the percentage of fiber weight, and the weight-to-bath ratio 1:10, rise to 95°C at 1.5°C / min, keep warm for 120min.

[0029] The viscose fiber treatment process is as follows: in the bulk fiber dyeing machine, add 1% of penetrant and 3% of deoiling spirit in the fiber weight percentage, the weight bath ratio is 1: 15, and rise to 90°C at 2°C / min. Keep warm for 45 minutes.

[0030] Step b: coloring processing of loose fibers: coloring the cotton fibers treated in step a to remove impur...

Embodiment 3

[0035] Spinning a kind of " core layer " that yarn count is 30s is polyester staple fiber, and " cortex " is the white core ring dyeing yarn of cotton fiber, specifically comprises the following steps:

[0036] Step a: Removing impurities and decolorizing treatment of loose fibers.

[0037] The cotton fiber treatment process is as follows: add 1.5% of penetrant, 8% of hydrogen peroxide, 12% of sodium hydroxide, 4% of hydrogen peroxide stabilizer CBI in the bulk fiber dyeing machine, and the weight-bath ratio 1:15, rise to 95°C at 1.5°C / min, keep warm for 120min.

[0038] The polyester fiber treatment process is as follows: in the bulk fiber dyeing machine, 1% penetrating agent and 2% deoiling spirit are added in sequence according to the percentage of fiber weight, the weight bath ratio is 1:10, and the temperature is raised to 80°C at 1.5°C / min 60min.

[0039] Step b: coloring processing of loose fibers: coloring the cotton fibers treated in step a to remove impurities and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com