Absorbent for capturing or separating carbon dioxide and its application

A carbon dioxide and absorbent technology, applied in the direction of absorption, separation method, dispersed particle separation, etc., can solve the problems of restricting the effective absorbent concentration, increasing the volatility of liquid ammonia, and increasing the corrosiveness, achieving high economy, reducing Viscosity, low corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

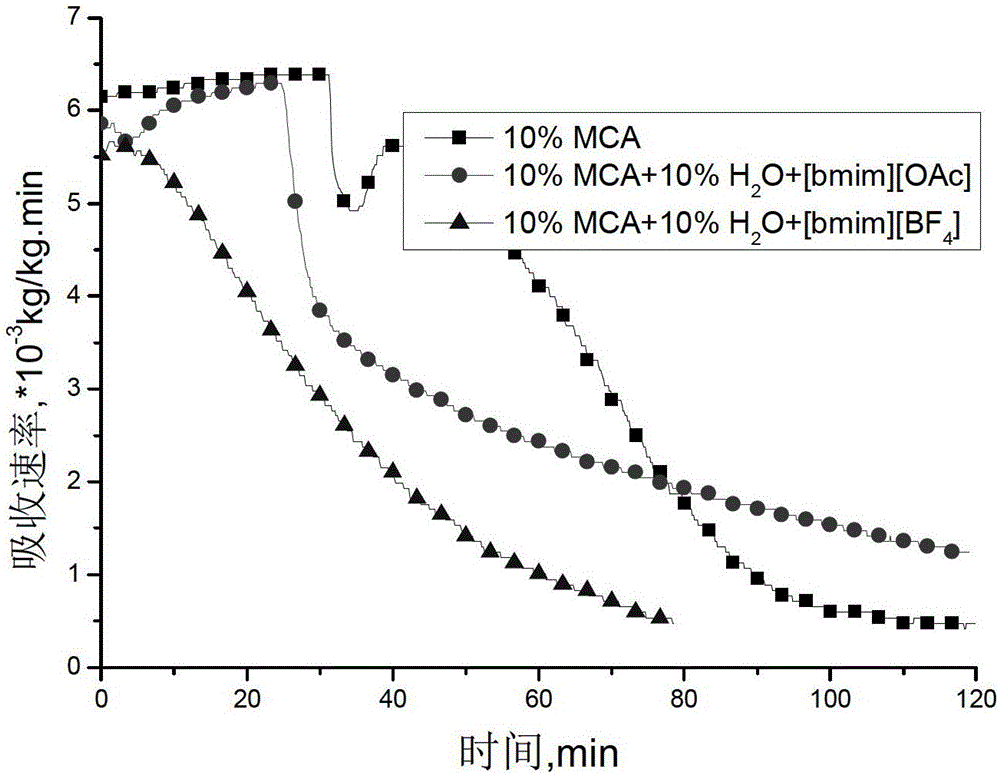

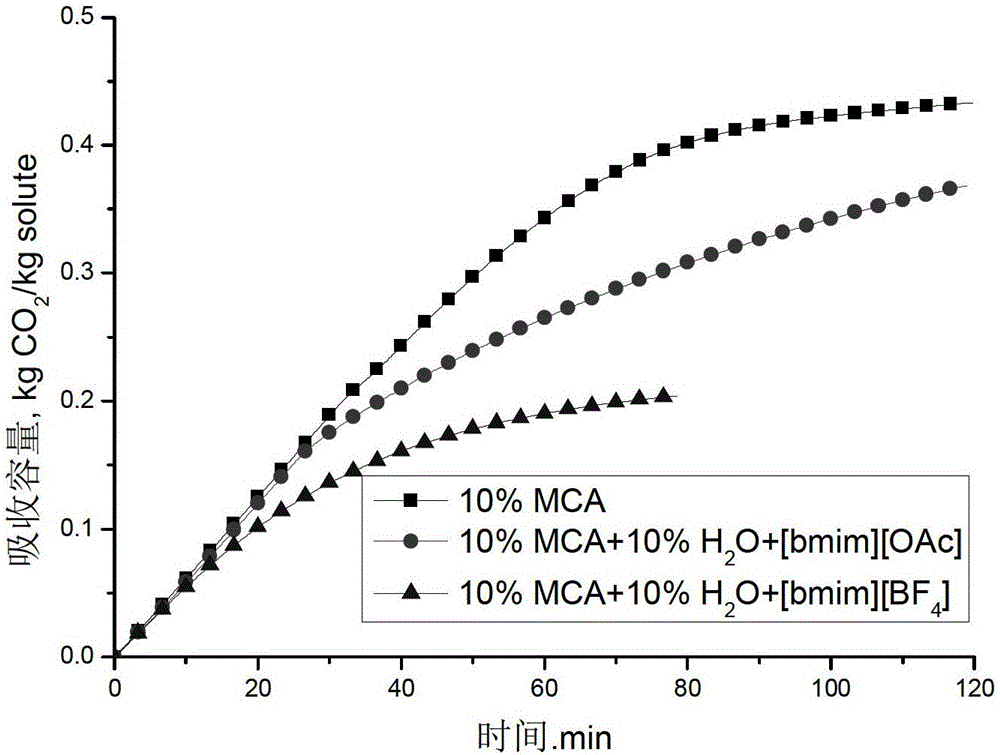

[0035] Mix 50g N-methylcyclohexylamine MCA (mass fraction 10%) with 50g deionized water (mass fraction 10%), add to 400g [Bmim][OAc] ionic liquid preset in a beaker, stir evenly, and obtain absorbent. Measure 50g of the absorbent and put it in an absorption bottle. After the absorption bottle is placed in a constant temperature water bath at 40°C for 10 minutes, the pressure is set to normal pressure, and the CO2 of 16.35mL / min is used. 2 and 120mL / min of N 2 The composition simulated coal-fired flue gas is introduced into the absorption bottle, and the weight of the absorption bottle is weighed at regular intervals. If the weight of the absorption bottle does not change, it can be considered that the absorption has reached equilibrium. The final CO absorbed 2 is 1.84g. The absorbed system was regenerated at 101 °C for 20 min, and the regeneration rate was 38.26%.

[0036] Control the absorption temperature, absorption pressure, stirring rate, absorbent quality, amine acti...

Embodiment 2

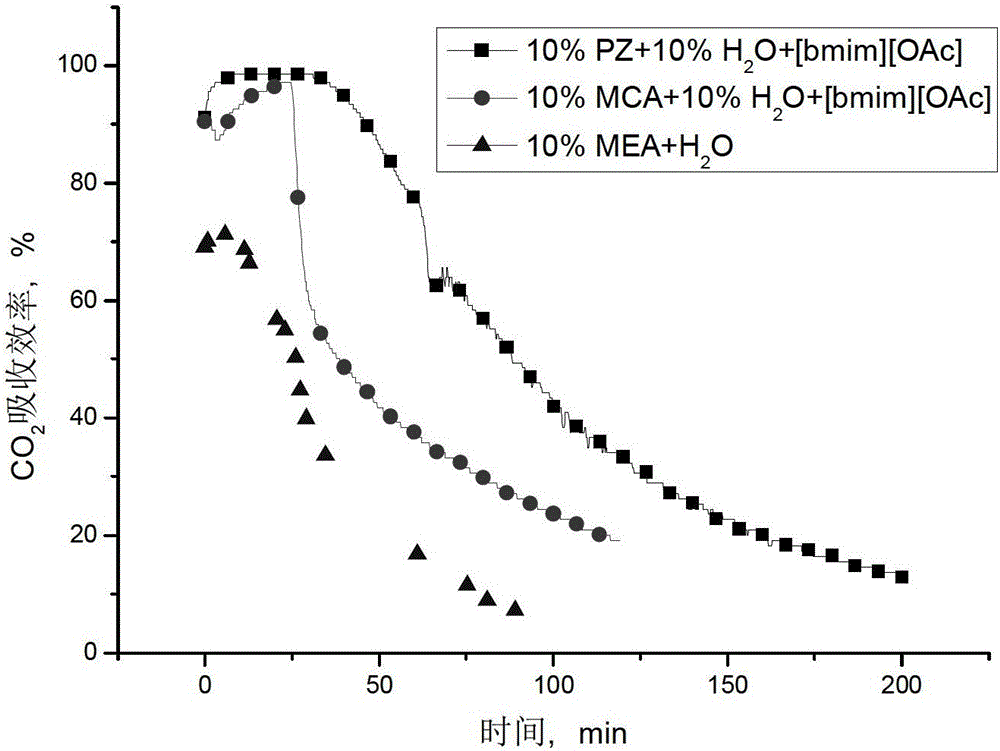

[0038] Mix 50 g of piperazine PZ (10% by mass) with 50 g of deionized water (10% by mass), add it to 400 g of [Bmim][OAc] ionic liquid preset in a beaker, and stir evenly to obtain an absorbent. Measure 50g of the absorbent and put it in an absorption bottle. After the absorption bottle is placed in a constant temperature water bath at 40°C for 10 minutes, the pressure is set to normal pressure, and the CO2 of 16.35mL / min is used. 2 and 120mL / min of N 2 The composition simulated coal-fired flue gas is introduced into the absorption bottle, and the weight of the absorption bottle is weighed at regular intervals. If the weight of the absorption bottle does not change, it can be considered that the absorption has reached equilibrium. The final CO absorbed 2 is 3.37g. The absorbed system was regenerated at 101 °C for 20 min, and the regeneration rate was 47.02%.

[0039] Control the absorption temperature, absorption pressure, stirring rate, absorbent quality, amine activator q...

Embodiment 3

[0042] Mix 50g N-methylcyclohexylamine MCA (mass fraction 10%) with 75g deionized water (mass fraction 15%), add it to 375g [Bmim][OAc] ionic liquid preset in a beaker, stir evenly, and obtain absorbent. Measure 50g of the absorbent and put it in an absorption bottle. After the absorption bottle is placed in a constant temperature water bath at 40°C for 10 minutes, the pressure is set to normal pressure, and the CO2 is 16.35mL / min. 2 and 120mL / min of N 2 The composition simulated coal-fired flue gas is introduced into the absorption bottle, and the weight of the absorption bottle is weighed at regular intervals. If the weight of the absorption bottle does not change, it can be considered that the absorption has reached equilibrium. The final CO absorbed 2 is 1.47g. The absorbed system was regenerated at 101 °C for 20 min, and the regeneration rate was 50.38%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com